Practicing Mechanical Weeding on the Inter-row - Hoeing

The hoe is a mechanical weeding tool working in the inter-row of already established crops that have been hoed. It acts by cutting or uprooting weeds and by stirring the soil in the inter-rows. It also allows breaking crusts and earthing up, depending on the different hoeing elements used. Finger or rotary hoes are adapted to work on the row.

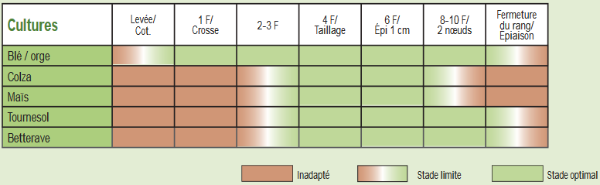

The hoe is effective on a wide range of weeds (grasses and annual dicotyledons) from emergence up to advanced development stages (see page 2 Hoe, CUMA Ouest). It is not effective against perennials because its working depth is too shallow. Unlike the hoe and the harrow tine harrow, it slows their growth but risks generating rhizome cuttings. It is an alternative to herbicide use in crops.

It is possible to hoe after the crop has fully emerged and the rows are visible or as soon as the weeds emerge, before the crop exceeds the height of the tool carrier. Hoeing before crop emergence is possible if it benefits from RTK guidance.

Success conditions:

To succeed in weeding with the hoe, it is important to ensure soil leveling at sowing or planting to avoid clods and uneven emergence. The soil must be flat, firmed, and sufficiently dried without being too dry. It is less effective in the presence of excessive crop residues. The presence of plant debris slightly reduces tool efficiency, whereas the presence of stones decreases effectiveness.

The intervention must be followed by one or two days of dry and sunny weather to ensure desiccation of uprooted weeds.

Equipment:

Hoeing elements (1 per inter-row) are fixed to a central beam but are independent and can be adjusted to different spacings. These elements have one to five working parts, the type of which determines aggressiveness and action on the soil and weeds. There is a wide variety (see The hoe, ARVALIS-Institut du végétal) and they can be combined.

Plant protectors can be used during hoeing at young crop stages to avoid covering the row.

Hoes can also be equipped with a guidance system (manual guidance, front hoe, camera, satellite, etc.), which provides comfort, precision of work, and higher work rates. It is essential in cereals.

The working width must be the same as that of the seeder or planter to facilitate guidance and work precision.

The aggressiveness of the hoe is defined by:

- The rigidity of the tines on which the shares are fixed and the working depth of the soil: the more rigid the tines, the deeper they penetrate the soil. The depth should be between 2 and 6 cm. Adjustment is done via the gauge wheel on each hoeing element.

- The type of share used

- The penetration angle of the share: the more vertically the share penetrates the soil, the deeper the work and the more soil is stirred, with a favorable action on the crust of surface crusting and a risk of bringing new weed seeds to the surface.

The recommended speed ranges from 3 km/h during the first pass (young crop stages) to 10 km/h for later passes. With autoguided systems, it is possible to advance at 14 km/h.

Technique details:

The hoe is to be used in mechanical weeding strategies complementing the tine harrow and rotary hoe, or mixed. It is rather reserved for passes at more advanced stages of the crop and weeds and can be combined with localized spraying elements (spot weeding), treating the row.

Source: The hoe, Agrotransfert

It is also possible to hoe on faba bean from 4-5 leaves, on soybean from the first trifoliate leaf stage, and on vegetable crops.

Implementation period On established crop

Spatial scale of implementation Plot

Application of the technique to...

All crops: Easily generalizable

Technique easily generalizable on established crops with sufficient spacing for the passage of hoeing elements (minimum 15 cm). It is feasible at narrow spacing (up to 17.5 cm spacing) provided a high-performance guidance system (RTK, camera, etc.) is available.

All soil types: Generalization sometimes tricky

Hoeing effectiveness is limited in clay-loam soils with flint (high wear) and in hydromorphic loams (see page 19 Mechanical weeding of field crops, ITAB)

All climatic contexts: Easily generalizable

One to two dry days must follow the intervention to ensure desiccation of weeds.

Regulation

The acquisition of hoeing tools for row crops is subject to a fiche CEPP (action no. 30: Weeding crops in rows using a mechanical weeding tool).

2. Services provided by the technique

Regulation and weed management

The hoe destroys weeds by uprooting or cutting, by delaying the growth of perennial weeds (drying by exposure to air) making them less competitive with the crop, or by covering seedlings on the row.

Effect level: MEDIUM if used alone, to be combined

Confidence index: HIGH

COMPLEMENTARY TECHNIQUE(S)

Mechanical full-field weeding practice - Tine harrow

Mechanical full-field weeding practice - Rotary hoe

INCOMPATIBLE TECHNIQUE(S)

Water storage and water management

Hoeing improves water infiltration into the soil and limits evaporation by breaking the surface crust and suppressing capillary rise. Hence the saying "one hoeing is worth two waterings".

Effect level: MEDIUM if used alone, to be combined

Confidence index: HIGH

COMPLEMENTARY TECHNIQUE(S)

INCOMPATIBLE TECHNIQUE(S)

3. Effects on the sustainability of the cropping system

"Environmental" criteria

Effect on air quality: Decreasing

pesticide emissions: DECREASE

GHG emissions: INCREASE

Effect on water quality: Variable

pesticides: DECREASE

turbidity: VARIABLE

Effect on fossil resource consumption: Increasing

fossil energy consumption: INCREASE

Other: No effect (neutral)

As an alternative to chemical weeding, hoeing reduces the use of herbicides and thus their transfer to water and air.

Fossil energy consumption and GHG emissions: link=|alt=yellow face size 10

Increasing, as hoeing consumes more fuel compared to a sprayer and requires more interventions for optimal effectiveness.

"Agronomic" criteria

Productivity: Variable

Using the hoe can cause plant losses if the intervention is poorly conducted and crops are not protected by plant protectors during sensitive stages. However, the soil aeration effect and improved water status can lead to a slight yield increase (some references in maize silage), as well as reduced competition from weeds.

Soil fertility: Increasing

There is a reduction in surface crusting and erosion due to increased soil aeration, with possible acceleration of mineralization.

Water stress: Increasing

Improved water infiltration into the soil and reduced evaporation

Other agronomic criteria: Decreasing

Slug regulation: Increasing

Soil work in the inter-row can destroy or disrupt the development cycle of slugs.

"Economic" criteria

Operating costs: Variable

Impact on operating costs is low, as increased fuel consumption is offset by reduced herbicide purchases: between -25% to -50% herbicides in situations maintaining mixed weeding (mechanical and chemical) compared to all-chemical weeding.

However, in case of too late hoeing or limited effectiveness, a chemical "catch-up" can greatly increase costs (hoeing is effective but technically more difficult to succeed).

Mechanization costs: Increasing

Requires an investment ranging from €4,000 to €40,000 depending on hoe types, widths, brands, accessories. The price of a guidance system must be considered: between €6,000 and €15,000 depending on the system.

Combined (mechanical and chemical) or all-mechanical itineraries have an additional cost of at least €10 to €20/ha compared to all-chemical itineraries.

Margin: Variable

Depends on the cost of herbicides replaced and additional working times to be integrated.

"Social" criteria

Working time: Increasing

Passes are slower than chemical weeding (1 ha/h for a 4-row to 6 ha/h for an 8-row autopiloted) and more frequent, resulting in a tripled working time compared to all-chemical weeding.

Peak period: Variable

Intervention windows can be short some years, especially when spring is wet. Adjustments are sometimes tricky and possible intervention windows can be short or nonexistent some years, especially when spring is wet.

Available slots for use are limited on maize (see available days maps in the brochure Mechanical weeding of field crops, page 57, ITAB).

Observation time: Increasing

Increasing as it requires regular monitoring of plots.

4. Benefited or disadvantaged organisms

Favored Bioagressors

| Organism | Impact of the technique | Type | Details |

|---|

Disfavored bioagressors

| Organism | Impact of the technique | Type | Details |

|---|---|---|---|

| Annual weeds | MEDIUM | weeds | |

| Perennial weeds | MEDIUM | weeds |

Favored Auxiliaries

| Organism | Impact of the technique | Type | Details |

|---|

Disfavored Auxiliaries

| Organism | Impact of the technique | Type | Details |

|---|

Favored climatic and physiological accidents

| Organism | Impact of the technique | Details |

|---|

Disfavored climatic and physiological accidents

| Organism | Impact of the technique | Details |

|---|

5. For more information

- Mechanical weeding of field crops

- -Hélène Sicard, Laurence Fontaine et al.

ITAB - CASDAR project "Optimizing and promoting mechanical weeding" 2009-2011, Technical brochure, 2012

The brochure describes the basics of mechanical weeding common to all crops then details, crop by crop, the conditions of use of different mechanical weeding tools, their optimal use conditions, and their integration into mechanical weeding technical itineraries in organic farming.

- Alternative mechanical weeding guide in vegetables - Picardie region

- -Ecophyto, Technical brochure, 2014

- Practical guide for designing vegetable cropping systems saving phytosanitary products. Technical sheet T17.

- -Launais M., Bzdrenga L., Estorgues V., Faloya V., Jeannequin B., Lheureux S., Nivet L., Scherrer B., Sinoir N., Szilvasi S., Taussig C., Terrentroy A., Trottin-Caudal Y., Villeneuve F.,

Ministry in charge of agriculture, French Agency for Biodiversity, GIS PIClég., Book, 2014

- The hoe

- -Pierre Mischler

Agro-Transfert, Technical brochure, 2007

- The hoe, a versatile tool adapted to a wide range of soils

- -ARVALIS-Institut du Végétal, Website

- Presentation, settings and usage ranges – HOE – CA17

- -CA17, Multimedia, 2017

- Hoeing fresh vegetables shallots

- -Rés'agri Légumes 29, Multimedia, 2016

- Mechanical weeding: hoe

- -Chambers of Agriculture of New Aquitaine, Technical brochure, 2016

- Alternative weeding in market gardening - Curative measures

- -Ferrier J-D.

Chamber of Agriculture of Ain, Technical brochure, 2016

See page 16

6. Keywords

Bioagressor control method: Physical control

Mode of action: Catch-up

Type of strategy regarding pesticide use: Substitution

Annexes

Est complémentaire des leviers

- Mechanical full-field weeding practice - Tine harrow

- Mechanical full-field weeding practice - Rotary hoe

Contribue à

S'applique aux cultures suivantes

Défavorise les bioagresseurs suivants