Mechanical weeding

Weed management using agricultural tools (curly harrow, rotary hoe, etc.)

Weed management using agricultural tools (curly harrow, rotary hoe, etc.)

Solutions for controlling weeds existed long before the arrival of plant protection products. They were either preventive (working the soil, rotation or mulching) or curative( manualweeding, mechanical weeding for certain weeded crops, etc.). After the Second World War, herbicides made weed control faster and more effective. Their widespread use is now showing its limitations. Mechanical weeding may be one way of reducing the risks associated with the use of chemical methods.

Principle

Weed control without herbicides is first and foremost a preventive approach, with mechanical weed control as a complement (its effectiveness on its own is limited).

It is important to remember that herbicide-free cropping system strategies are based on two essential concepts :

- Regular observation of plots and knowledge of the weed flora and the biology of the species that make it up are the basis of any management strategy implemented by the farmer.

- The aim is to control weeds, not eliminate them. In other words, we talk about weed tolerance, as weeds can be present in plots without affecting the production of future crops. Some even see advantages, as weeds help to increase biodiversity and support the development of auxiliary fauna.

Why use mechanical weeding?

In recent years, the withdrawal of active substances has accelerated without any alternative solutions being proposed. This has sometimes led to technical impasses. Whether or not it complements chemical weeding, mechanical weeding can provide a more cost-effective and efficient solution. Replacing certain treatments with mechanical tools can help to anticipate regulatory changes.

Mechanical weeding reduces the impact of active substances on the environment and avoids water pollution. In the pre-emergence phase, it limits the use of root herbicides, which are considered to be the most harmful and risk being washed into water tables.

Mechanical weeding is not only useful for controlling weeds, it also has recognised agronomic advantages. Depending on the equipment used and the conditions at the time of application, mechanical weeding can limit run-off by destroying the crust of soil, aerating and levelling the soil, reducing water evaporation, positioning fertilisers, boosting soil microbial life and encouraging the mineralisation of organic matter.

According to some authors, two or three hoeing operations can save twenty or more units ofnitrogen.[1]. The use of mechanical tools also reduces water loss from the soil, by disrupting evaporation in the first few centimetres of soil.

Thanks to new technologies, in particular guidance, the use and performance of mechanical weeding tools are now optimised, capable of adapting to a wide range of crops and situations. These innovative systems make it possible to work faster and more accurately.

The tools

Weeder harrow

The currycomb har row works at a depth of around 2 cm (and up to 4 cm for pre-emergence work) independently of the crop rows, enabling weed control to be carried out over the entire surface. Its flexible tines vibrate as the tool moves forward, uprooting weeds by tearing them up through vibration and impact.

The tines, spaced 2 to 3 cm apart, can be straight or curved. Curved tines are more aggressive than straight tines, but less suited to very stony soils. They are mounted on different independent panels to ensure good grip on the soil and good tracking of its unevenness.

There are numerous settings to choose from: forward speed, working depth, tine inclination and, above all, the pressure applied to the tines.

It can be used pre-emergence, then from the 2-3 leaf stage until fairly late in the season without taking too many risks. Its impact will be effective on very young weeds up to the 1-2 leaf stage.

Weed management should be carried out on reconsolidated, levelled and reconsolidated soil to ensure it works properly. If the soil is not clean, there is a risk of the tool jamming. Its effectiveness is limited on threshing soil.

The rotary hoe

The rotary hoe works at a depth of around 2 cm, independently of the crop rows, and can therefore be used to weed the entire surface. It is fitted with spoon-tipped wheels that dig, loosen, pull up and then throw up weeds.

The tool's high penetration power makes it effective on loose soil. It can also be used as a crust-breaker.

It is advisable to work on weeds between the germination and cotyledon stages.

There are few possible adjustments: forward speed, pressure on the working elements, depth.

It is difficult to use on stony soil.

The weeder

The shares of the hoe cut or loosen the roots and can bury young weeds by bringing soil up to the row. It weeds between the rows of row crops, with more or less wide spacing depending on the precision of the guidance.

The various hoeing elements (1 per row) are fixed to a central beam but are independent and can be adjusted to different spacings. These elements comprise one to five working parts, the type of share determining their action on the soil and weeds.

In cereals, guidance is virtually indispensable, as the spacing between rows is very narrow and damage to the crop can be significant if the machine does not stay in the right place. Guidance can be mechanical (trace wheel) or electronic (GPS, camera). It is also possible to mount the tool on the front linkage for greater precision.

Hoeing is not recommended at crop emergence, but rather for late passes at least up to the 1-node stage. Good effectiveness on weeds even beyond the 2-3 leaf stage.

Several settings: working depth, pressure exerted on each element.

Choice of tool

Mechanical weeding can be applied using a range of tools. Some are complementary, others have similar actions. The perfect all-purpose tool does not yet exist. The choice of mechanical weeding tool depends on the crop, its stage, the type of soil and also the weeds.[1].

Depending on the crop stage

| Weederharrow | Rotary hoe | Weeder | |

|---|---|---|---|

| Sowing densities | Increase sowing densities by 10% in anticipation of plant losses due to the passage of tools. | ||

| Spacing between rows | No adjustments required | Spacing must be regular, straight and adapted to the weeder used. | |

| Guidance system/plant protector | Not necessary | Strongly recommended | |

| Target crops | Can be used on all crops | Suitable for row crops | |

| Pre-emergence weed control | No crop damage | High risk of crop damage | |

| Post-emergence weed control | No crop damage (but only effective if weeds are at a young stage) | Little damage to the crop | |

Depends on soil type

For these 3 tools, the soil must be levelled and reconsolidated, with no large plant debris.[1]

Depending on the weed flora

F=leaf

The harrow and hoe can be used to weed the entire surface. The hoe is very effective in the inter-row (it can also be used in the row with flexible fingers or ridging).

The roto-weeder, the new mechanical weeding tool

The roto-chopper is a recent tool, halfway between the currycomb harrow and the rotary hoe. It is made up of round-toothed discs with a diameter equivalent to that of a currycomb harrow. However, each disc has an angle of attack similar to that of a disc harrow. The entire width of the tool is worked, as the discs intersect slightly.

The action of the tines and the angle of the discs will lift a thin layer of soil and destroy weeds by uprooting or covering them.

It is effective on very young weeds, but also up to the 2-3 leaf stage on broadleaf weeds.

There are a number of settings: the horizontal position of the machine, the working depth, the pressure applied to the elements and the forward speed.

As there is no raking effect, there is no clogging due to residents on the surface of the plot. However, the soil must be well levelled and fairly well prepared.

Including mechanical weeding in an agronomic strategy

Under certain conditions, mechanical weed control is not as effective as chemical weed control : to prevent plots from becoming dirty, the entire cropping system needs to be reviewed to try and reduce the seed bank. Extending crop rotations by alternating spring and autumn crops improves the effectiveness of mechanical weeding. Alternating ploughing/no ploughing and repeated stubble ploughing in summer depletes the seed stocks of certain species, particularly grasses.

Reconciling weather and mechanical weeding

For example, when stubble ploughing cereals, if the weather conditions allow a " blind " pass in the autumn, efficiency will be increased. Then, at the end of winter, as soon as the soil has sufficiently dried out, you need to start mechanical weeding again. You need 2 or 3 days without rain to prevent seedlings from taking root. On the other hand, if conditions are too dry at the time, there is an increased risk of cutting the roots of the crop.

The limits of mechanical weeding

- For some weeds, it is necessary to intervene at a very precise stage, so weather conditions must be favourable at the time for the tool to be used.

- Mechanical weeding in the early stages of a sown crop entails a risk of uprooting or injuring young seedlings, as they are shallow-rooted.

- Hoeing can amplify the phenomenon of cuttings.

Techniques to master

Each intervention condition (crop stage, soil texture, humidity conditions, etc.) requires a suitable tool (blades, tines, currycombers, etc., in the middle or between rows, etc.), which means that these techniques need to be mastered.

Indicative costs

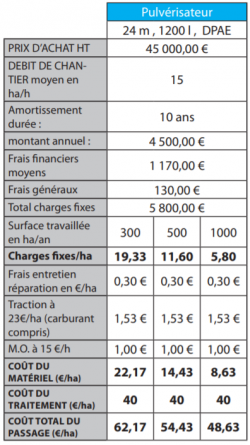

Cost of a mechanical weeding pass[1] :

By way of comparison, the cost of one spray pass with a herbicide is €40/ha (including filling and rinsing time):

Sources

- Mechanical weeding - La France Agricole

- Reducing and improving the use of plant protection products - Ecophyto

- Mechanical weeding in field crops - ITAB Asso

- Mechanical weeding: Adapting the tool to the farm context - Arvalis-infos