Mechanical Weeding in the Open Field - Rotary Hoe

The rotary hoe, or crust breaker, is a mechanical weeding tool used in the open field, without a guidance system. It acts mechanically on weeds during germination, uprooting and throwing them into the air along with the top two centimeters of soil. A density-based sorting occurs, and the seedlings of weeds end up on the surface to dry out.

It is used either blindly pre-emergence or post-emergence as soon as weed emergence is observed (in this case, the sowing must be regular and slightly deeper).

It is effective on all weeds during germination (see page 2 The rotary hoe, AgroTransfert) but ineffective on developed weeds, including perennials. It is an alternative to the use of pre- and post-emergence herbicides. It can also be used to destroy false seedbeds and, in this case, represents an alternative to glyphosate use.

Conditions for success:

To succeed in weeding with a rotary hoe, the seedbed must be sufficiently consolidated and well leveled to control the working depth of the tool. It must be sufficiently dry without being too dry, as the presence of a crust of surface crusting that is too dry and thick reduces the penetration of the blades into the soil and penalizes the effectiveness of mechanical weeding. It is less effective in wheel tracks and on tramlines.

To be effective, intervention must occur before the two true leaf stage of weeds because effectiveness decreases when weeds exceed the "cotyledon" stage. Generally, one or two passes are made, depending on the number of days available (see map for mechanical weeding of wheat in autumn). One to two dry days should follow the intervention to ensure weed desiccation.

Sowing density should be increased by 10% to compensate for plant losses.

Equipment:

The rotary hoe consists of numerous star-shaped wheels mounted on a spring-loaded arm and equipped with fingers ending in blades. Different types of equipment exist (blades more or less flattened, wheels mounted independently or in tandem, springs and depth wheels…).

Its aggressiveness depends on:

- Working speed: it must be at least above 10 km/h to properly uproot and throw weeds and soil clods. The optimal speed is estimated at 18 km/h.

- Working depth: it is adjusted using gauge wheels and should not exceed 3 cm to avoid bringing up weeds.

- Pressure of the star wheels on the soil: the higher the pressure, the more aggressive the hoe. On most models, this pressure is constant. However, some manufacturers offer hoes where spring settings can be adjusted to apply more or less pressure.

Available widths range from 3 to 12 m. The 6 m width is the most common, as it represents a good compromise between price, traction power, and limiting wheel passes on the crop.

Details on the technique:

Very easy to use, the rotary hoe passes without difficulty in the presence of crop residues and/or in "wet" but non-sticky conditions. It is very complementary to other mechanical weeding techniques (harrow, hoeing) or chemical methods that can be used as complements or catch-up if weather conditions make intervention difficult (example: see page 2 The rotary hoe, AgroTransfert).

It can be used post-sowing pre-emergence on crops, at the "filament" stage of weeds. At this stage, it also serves to break any surface crust.

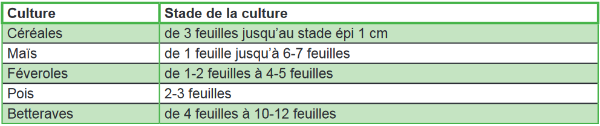

Used post-emergence, the rotary hoe must be used at specific stages depending on the crop:

Source: Mechanical weeding: the rotary hoe, Chamber of Agriculture Seine-et-Marne

It can also be used on soybean and sunflower (from 2 to 3 leaves), on rapeseed (from 1 to 3 leaves and beyond but with foliage shredding issues) or for the restoration of grasslands (low penetration). It is usable in seeded vegetable crops (bean, flageolet, pea) but not in transplanted ones.

For an example of integration into mechanical weeding itineraries in organic farming, see the attached trajectory sheet DEPHY.

Implementation period On established crops

Spatial scale of implementation Plot

Application of the technique to...

All crops: Easily generalizable

Technique adapted to many species, mainly to arable crops and in open-field vegetable crops sown (bean, flageolet, pea). However, care must be taken not to intervene during sensitive crop stages.

All soil types: Generalization sometimes delicate

This tool is particularly suited to loamy soils where it helps break surface crusting. It is not recommended on very stony soils (equipment wear, reduced effectiveness) and on clay-loam soils.

The rotary hoe can work on fresh, moderately dry soils. If the soil is too dry, the blades cannot penetrate.

For more information: see the article ARVALIS-Institut du Végétal Choosing the mechanical weeding tool according to soil type

All climatic contexts: Easily generalizable

One to two dry days should follow the intervention to ensure weed desiccation.

Regulation

The acquisition of a rotary hoe for row crops is subject to a fiche CEPP (action n° 30: Weeding crops in rows using a mechanical weeding tool).

2. Services provided by the technique

Regulation and weed management

The hoe destroys weeds by mechanical action (uprooting, covering with soil). It has a selective action towards the crop due to the differential development between weeds and the crop, which is either not emerged or better rooted.

Effect level: MEDIUM if used alone, to be combined

Confidence index: HIGH

COMPLEMENTARY TECHNIQUE(S)

Mechanical Weeding Between Rows - Hoeing

Mechanical Weeding in the Open Field - Harrow

INCOMPATIBLE TECHNIQUE(S)

Physical stability and soil structuring

The superficial soil work performed reduces the risk of surface crusting and erosion by improving soil aeration and breaking any formed surface crust (formation of a new crust remains possible). The rotary hoe also improves precipitation infiltration into the soil and reduces capillary rise.

Effect level: LOW, if used alone, to be combined

Confidence index: HIGH

COMPLEMENTARY TECHNIQUE(S)

INCOMPATIBLE TECHNIQUE(S)

3. Effects on the sustainability of the cropping system

"Environmental" criteria

Effect on air quality: Decreasing

pesticide emissions: DECREASE

GHG emissions: INCREASE

particle emissions: INCREASE

Effect on water quality: Variable

pesticides: DECREASE

turbidity: VARIABLE

Effect on fossil resource consumption: Variable

fossil energy consumption: VARIABLE

Other: No effect (neutral)

As an alternative to chemical weeding, the rotary hoe reduces the use of herbicides and thus their transfer to water and air.

Fossil energy consumption and GHG emissions: link=|alt=yellow face size 10

Increases if multiple mechanical weeding passes and/or chemical catch-up are needed compared to a herbicide treatment. Required traction is 20-25 hp/m of tool width.

"Agronomic" criteria

Productivity: No effect (neutral)

Using a rotary hoe can cause plant losses up to 5% depending on crop stage and soil conditions. However, this loss can be compensated by increasing sowing density by 10%.

Soil fertility: Increasing

Mechanical action promotes mineralization, aeration, and soil warming. It improves the positioning of phosphate and nitrogen fertilizers.

Functional Biodiversity: No known impact

Mechanical tool passes may disturb surface fauna (macro/micro).

Other agronomic criteria: Variable

New weed emergence:

The hoeing, by disturbing the soil at a shallow depth, promotes new weed emergence. However, these emerge later than the crop, which strongly competes with them.

"Economic" criteria

Operating costs: Variable

Impact is low, as increased fuel consumption is offset by reduced herbicide purchases. However, about 10% more seed is needed to compensate for plant losses.

Mechanization costs: Increasing

Requires an investment between €3,700 and €7,000 excluding tax for a 3 m hoe and about €10,000 for 6 m width.

Margin: Variable

The effect on margin depends on the balance between cost increases and reductions. It is more relevant to compare a strategy using the rotary hoe to an all-chemical approach than to evaluate the effect of adopting the hoe in isolation.

"Social" criteria

Working time: Increasing

Increased working time due to the narrow tool width compared to herbicide treatment: work rate of 4 to 6 h/ha depending on tool width

Peak period: Increasing

It can be difficult some years to find suitable intervention windows. Possible intervention periods can be short or even nonexistent some years.

Observation time: Variable

Observation time before intervention is the same as before a non-systematic herbicide treatment.

4. Favored or disadvantaged organisms

Favored Bioagressors

| Organism | Impact of the technique | Type | Details |

|---|

Disadvantaged Bioagressors

| Organism | Impact of the technique | Type | Details |

|---|---|---|---|

| Annual weeds | MEDIUM | weeds | Much less effective after weed roots are established. |

| Perennial weeds | MEDIUM | weeds | Much less effective after weed roots are established. |

Favored Auxiliaries

| Organism | Impact of the technique | Type | Details |

|---|

Disadvantaged Auxiliaries

| Organism | Impact of the technique | Type | Details |

|---|

Favored climatic and physiological accidents

| Organism | Impact of the technique | Details |

|---|

Disadvantaged climatic and physiological accidents

| Organism | Impact of the technique | Details |

|---|

5. For more information

- Mechanical weeding: Rotary hoe and topper

- -Chambers of Agriculture of New-Aquitaine, Technical brochure, 2016

- Mechanical weeding of arable crops

- -Hélène Sicard, Laurence Fontaine et al

ITAB - CASDAR project "Optimize and promote mechanical weeding", Technical brochure, 2012

The brochure describes the basics of mechanical weeding common to all crops then details, crop by crop, the conditions for use of different mechanical weeding tools, their optimal conditions of use and their integration into mechanical weeding itineraries in organic farming.

- Alternative weeding guide for vegetables in the Picardie Region. "Integrated Vegetable Production" Program

- -Chambers of Agriculture of Somme, Aisne and Oise. Agro-transfert Resources and Territories, Technical brochure, 2014

- Practical guide for designing vegetable cropping systems that economize phytosanitary products. Technical sheet T15.

- -Launais M., Bzdrenga L., Estorgues V., Faloya V., Jeannequin B., Lheureux S., Nivet L., Scherrer B., Sinoir N., Szilvasi S., Taussig C., Terrentroy A., Trottin-Caudal Y., Villeneuve F.

Ministry of Agriculture, French Agency for Biodiversity, GIS PIClég., Book, 2014

- The rotary hoe

- -Chapuis S.

LPC Bio, Technical brochure, 2013

- Mechanical weeding practice: The rotary hoe

- -Pierre Mischler

Agro-Transfert Resources and Territories, Technical brochure, 2011

- The rotary hoe on maize to reduce pesticide use

- -Res'agri 29, Multimedia, 2018

- Presentation, settings and usage windows – ROTARY HOE

- -CA17, Multimedia, 2017

- Reduction of pesticide use: strategies implemented in the DEPHY FERME network - arable crop sector - mixed farming

- -Félix I. et al

DEPHY - Ecophyto, Technical brochure, 2018

The brochure describes 16 families of pesticide use reduction strategies observed in different production contexts among farmers in DEPHY groups. Strategy 11 ("In livestock farms in western France, multi-species grazed grassland-based systems for conversion to organic farming") describes several all-mechanical weeding itineraries on maize, integrating the rotary hoe in complement to hoeing and, in some cases, the harrow.

6. Keywords

Bioagressor control method: Physical control

Mode of action: Catch-up

Type of strategy regarding pesticide use: Substitution

Annexes

Est complémentaire des leviers

Contribue à

S'applique aux cultures suivantes

Défavorise les bioagresseurs suivants