Rotary hoe

The rotary hoe is a mechanical weeding tool used in open fields. It consists of star-shaped wheels mounted on a spring-loaded arm, equipped with fingers ending in a spoon-shaped tip.

Operating principles

By penetrating the soil, the spoons dig, loosen, uproot, and cover the aerial parts.

This tool can be used in open fields on many crops such as wheat, sunflower, sorghum, maize, barley, soybean, rapeseed, bean, and seed-bearing plants…

The rotary hoe is a simple-to-use tool that requires few adjustments. The aggressiveness of the tool largely depends on the travel speed and the working depth of the soil (the higher the pressure of the wheels on the soil, the more aggressive the hoe). The hoe is preferred on crusted soils for its crust-breaking function.

Tool characteristics

The rotary hoe consists of star-shaped wheels spaced 7 to 9 cm apart, with spoon-shaped ends that dig, uproot, and throw weeds. As a mechanical weeding tool used in open fields, like the harrow, it allows “blind” weeding, post-sowing before crop emergence, but it should not be used during the delicate crop emergence stage. Also called “crust breaker”, the rotary hoe breaks the crust, particularly useful in loamy soils of the boulbène type.

Usage

The rotary hoe is passed at a shallow depth, about 2 cm, over the entire crop surface. Few adjustments are needed to use a rotary hoe. The main factor affecting the tool's effectiveness is the forward speed. For effectiveness, a rotary hoe pass must be done at a speed of at least 10 km/h, up to 15 km/h: at this speed, the rotation of the star wheels is optimal and the uprooting of weeds is maximal. Its work rate is therefore high: from 5 to 8 ha/h depending on speed but also on the tool's width (generally from 3 m to 9 m).

Another adjustment to optimize aggressiveness is the penetration depth of the spoons. It can be adjusted using gauge wheels and/or depth wheels, pressure springs, or by placing weights on the frame. However, a major drawback of this tool is its low effectiveness on developed weeds, compared to the harrow, especially the spring-tooth harrow. Indeed, it is difficult for a rotary hoe to uproot weeds that have passed the 2-3 leaf stage. Its combination with the spring-tooth harrow is therefore interesting, since the crust of soil crusting hinders the passage of the latter, the teeth possibly sliding on the surface of a crusted soil and not penetrating enough to weed. The spring-tooth harrow is also more aggressive on more developed weeds, so it can be used after a first crust-breaking pass with the rotary hoe, for example “blind”.

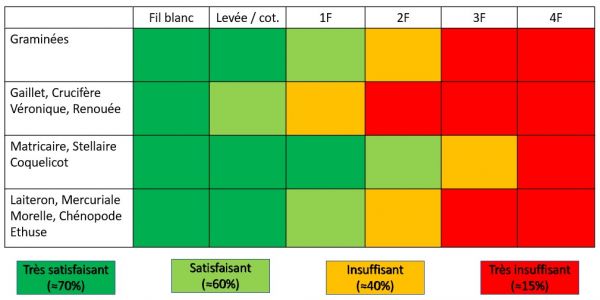

Effectiveness depending on weed development stage

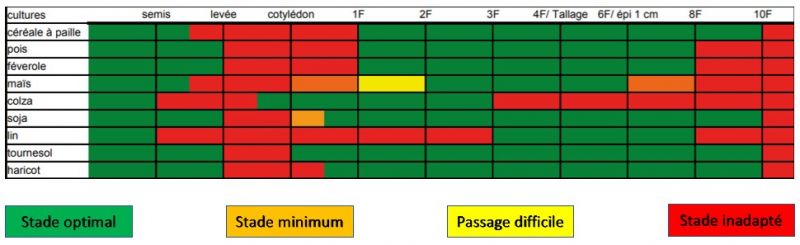

Usage ranges

Strengths and weaknesses

Strengths

- Few adjustments

- Versatile tool

- High work rate: 5-8 ha/h

- Usable on many crops

- Breaks soil crust

- Wide spectrum of effectiveness on weed seedlings

- Economical and low maintenance

- Little sensitivity to plant debris

- Row weeding

- Usable in windy conditions

- Avoids selection of herbicide-resistant herbicides-resistant weeds

Weaknesses

- Short intervention periods relative to weed development

- Ineffective on developed weeds and perennials

- Requires well-leveled soil preparation

- Low effectiveness in presence of stones or surface residues

- Requires power (20 to 25 hp/m)

- Sometimes delicate timing of interventions

Example of rotary hoe use according to crops excluding “blind” passes, possible post-sowing pre-emergence

1. Winter cereals

✓ Autumn or late winter: stage 1-3 leaves

✓ Late winter - early spring: tillering

2. Faba bean

✓ Stage 2-4 leaves

✓ Stage 6-8 leaves

3. Maize - Sorghum

✓ Stage 3 leaves

✓ Stage 5-6 leaves

4. Soybean

✓ Stage first unifoliate leaves

✓ Stage first trifoliate leaves

5. Sunflower

✓ Cotyledon stage (caution, sensitive stage for sunflower: do not exceed 10 km/h)

✓ First leaf pair

Selection criteria

| Points of attention | Comments |

|---|---|

| The frame can be mechanically foldable (small widths) or hydraulic (U or portfolio/double effect) | Hydraulic folding has a significant impact on price but is essential from 4.5 m width onwards |

| The traction power is important and must be related to the optimal effective speed of the tool | The traction demand is 20 hp per linear meter. The tractor must be able to quickly reach 16 km/h, otherwise effectiveness will not be optimal.

Hatzenbichler rotary hoes are less demanding in terms of speed, traction demand is lower. Low-pressure tires allow driving on maize up to the 4-leaf stage. |

| Hydraulic adjustment of the wheel pressure on the soil | Interesting criterion generating an additional cost (5000 to 6000) |

| Spacing between two wheels | This criterion is mainly important to have the maximum worked surface. Too narrow spacing can cause blockages on stony soil or with significant residues on balance-arm systems. |

| Shape of the wheel ends | Prefer the shape of spoon-shaped teeth.

Reversed wheels require less speed and thus less power but tend to break maize. |

| The weight of the tools ranges from 1.35 t to 2.4 t | This criterion is important: the heavier the rotary hoe, the better the wheels will penetrate the soil, especially on crusted soil |

| Matching tractor track width and power | Keep a sufficient safety margin between the tractor wheel and the crop considering the high working speed. |

Different models

| Manufacturer | Model | Minimum width | Maximum width | Type of rotary hoe | Spoon orientation | Reference price (for a 6m rotary hoe) | Details |

|---|---|---|---|---|---|---|---|

| Yetter | HR Yetter | 3 m | 12 m | Independent arm | Tip attacks the soil | €16,000 | Details |

| Agronomic | HR Agronomic | 3.2 m | 6 m | Balance arm | Tip attacks the soil | €27,500 | Details |

| APV | Rotary Crusher | 6 m | 12 m | Independent arm | Unknown | €23,600 | Details |

| Agrokraft | Stern | 3 m | 12 m | Balance arm | Tip attacks the soil | €20,000 | Details |

| Pöttinger | Rotocare | 6.6 m | 12.4 m | Independent arm | Tip attacks the soil | Unknown | Details |

| Ferju-Gourdin | HR Rotario | 3 m | 6.3 m | Balance arm | Tip attacks the soil | €25,440 | Details |

| Eurotechnics | Rotaking | 3 m | 12.4 m | Independent arm | Tip attacks the soil | €19,000 | Details |

| ETR AVT | HR ETR AVT | 3 m | 9 m | Balance arm | Tip attacks the soil | Unknown | Details |

| Spedo | HR Spedo | 2.6 m | 6.1 m | Balance arm | Tip attacks the soil | €15,500 | Details |

| Agrifarm | HR Bio Plus | 3 m | 24 m | Independent arm | Unknown | Unknown | Details |

| Badalini | Romeo | 3 m | 7.2 m | Balance arm | Tip attacks the soil | Unknown | Details |

| Hatzenbichler | HR Hatzenbichler | 3.3 m | 12.2 m | Balance arm | Back attacks the soil | Unknown | Details |

| Leroch Distribution | H-roto | 3 m | 12 m | Balance arm | Tip attacks the soil | €10,000 | Details |

| Özdöken | Rotokul K620 | 4.2 m | 6.2 m | Independent arm | Unknown | €18,600 | Details |

| Conpexim | Astra 2 | 3 m | 6 m | Balance arm | Tip attacks the soil | €13,000 | Details |

| Carré | Rotanet control | 4.8 m | 10.3 m | Independent arm | Tip attacks the soil | €39,100 | Details |

| Carré | Rotanet | 3 m | 12.4 m | Independent arm | Tip attacks the soil | €16,900 | Details |

Cost per hectare

Equipment + tractor + labor: €10/ha (4.5 m tool on 200 ha/year).

Article written with the support of:

Sources

- Organic letter July 2019 - Chamber of Agriculture of Ariège

- DEPHY-FG-CRAO2019 Collection

- Rotary hoe - Arvalis Infos

- Opti'Mat: https://optimat.org/outil/houe-rotative/

- Agro Transfert: http://www.agro-transfert-rt.org/wp-content/uploads/2016/02/La_houe_rotative.pdf