Longueil's Farm

Living soil and industrial crops

Guillaume and Antoine Chedru

In 1988, Antoine Chedru set up the family farm in the Pays de Caux region with his brother and father, as partners in a mixed farming (dairy) system that has since evolved considerably.

The very wet winters of 1993 and 1994 triggered a great deal of erosion in their conventional plots of loamy soil. Following this, Jean-François Ouvry (AREAS) raised awareness of the problem, noting that tillage amplified the erosion phenomenon. This prompted the farm team to completely revise their technical itinerary and even build their own equipment.

Since setting up, Antoine, and now his son Guillaume, are fully committed to an agroecological approach in the sense that they work on a system-wide scale, actively seeking to work with and not against natural ecosystems.

However, the system change did not happen with a snap of the fingers, but in an incremental way, punctuated by mistakes and uncertainties, supported by a dynamic of experimentation and local working groups.

Special features of the farm

- Reduced tillage with SD (direct seeding) + TCS (simplified cultivation techniques) + Plant cover crops and companion plants.

- Beet using strip-till without insecticides.

- Self-build.

- Development of biocontrol solutions such as fermented nettle extracts, comfrey, garlic maceration and development of effective microorganisms (EM).

Contextual data

| Farm name' | Ferme de Longueil |

| Location | Goderville, Seine-Maritime (76) |

| SAU | 160 ha |

| UTH | 1.25 (Antoine Chedru full-time and Guillaume 25%) |

| Crops | Beet, wheat, flax, rapeseed |

| Labels | HVE 3 |

| Groups | Sol en Caux |

Land context

| Soil texture | Loam loam, 60% loam |

| OM content at planting (%) | 1,7 |

| Last MO rate'

lab test (year n) |

2.8 (2023 analysis) |

| Soil PH 2020 (year n) | 7 |

| Bearing capacity, structure... | No rotary tillage, no plough tillage

Good bearing capacity, improved by plant cover crops |

| Earthworms per m²' | 110 |

Local climate data

| Local data | National data | |

|---|---|---|

| Annual rainfall

average |

Around 1200 mm per year"

(average 161 mm/month) |

155 mm/month |

| T°max moyenne' | 38 | 29 |

| T°min moyenne | -4.7 | 2,7 |

| First frost

usually |

December when there is" | |

| Type of climate' | Oceanic |

Source: Météo France

Transition stages

- 1995 : Stopped ploughing and switched to simplified tillage (TCS) with the farm's existing equipment. From this date on, with significant rainfall of 1000 to 1200 mm per year, Antoine no longer observed any erosion in his plots. He explains that the reason they switched to TCS was that the soil was not yet ready to "take care of itself". So they made a few deep passes with a stubble cultivator to "build up a structure conducive to root development". As the level of Organic Matter (OM) increased, the working depth decreased (first from 20 to 15 cm, then 10 cm).

- 2000: Antoine's brother leaves the farm, and an employee is hired to replace him.

- 2010 : They test strip-till beets.

- 2012 : End of dairy herd.

- Winter 2012-2013: Warning from the water agency following major mudslides on the roads and turbidity problems in the area. This is when most of the crops are planted using direct seeding.

- 2013: Creation of "Sol en Caux": emergence at last of a welded group at department level (15 farmers in the area).

- 2015 : Beginning of the implementation of plant macerations as an alternative to fungicides and the spreading of BRF (Bois Raméal Fragmenté).

- 2016 : Stop using insecticides.

- 2019 : 800mm of water in autumn, beginning of cracking trials due to crop loss caused by the fact that in Seine-Maritime, soils are generally made up of fine silts with a little clay (12% clay and 70% silts) which naturally take up mass. This phenomenon induces water stagnation, despite the fact that the farm was already in SD for rapeseed and wheat, and that tillage was very shallow for spring crops (which partly solved hydromorphic problems).

Effects of new practices

- Stop mudflows and floods, Hydromorphic management and more microporosity' in the soil.

- Growing potatoes by direct seeding, with Sol en Caux |Gain in soil fertility]] (OM has improved by 1 percentage point since the change in practices): "I find that since we've been working with a simplified seeding system, or even direct seeding, the soil's bearing capacity has improved considerably and, despite the rain, we're able to plant in excellent conditions because the organic matter level has risen and the soil is in much better health.

- Cost savings:' Today, the farm's biggest expense is the harvester.

- SD practices are favorable to the development of slugs and voles. Antoine therefore uses a [[[straw harrow]] after harvest, to expose slug eggs to the sun. He also uses Sluxx (Molluscicide) as a preventive measure, up to 15 days before sowing. For voles, he relies on natural predators, which he encourages with perches in the plots, as well as on the tillage he has maintained for certain crops (beet and flax).

- Effect of trials with companion plants / maceration, cumulated with the cessation of insecticides on pest pressure:' A Berlèse test was carried out in December 2021 to see the effect of stopping insecticides in rapeseed associated with faba bean. The result was 0.6 flea beetle/foot larvae, on a plot with 2.8 to 3% OM. A robust rapeseed that emerges more quickly from winter means that flea beetle larvae stay in the petiole and don't do as much damage to the stems.

- "'Since we've been working with a semi-simplified system, or even direct seeding, the soil's bearing capacity has improved considerably, and despite the rain, we're able to sow in excellent conditions, as the organic matter level has risen and the soil is in much better health."

Objectives

- "The objective is to continue doing a good job. To develop organic matter and have a self-fertilizing system, we need to perpetuate it because it can change overnight."

- Develop other crops like hemp at the same time as flax. It's complicated because of the vagaries of the weather.

Crop monitoring: rotation and technical itineraries

Crop rotation

On installation: wheat, rapeseed, fibre flax (peas or corn could also be grown, but at an additional cost). Since then, there has been a lengthening of the rotations and a diversification of crops, which has the merit of improving rye grass and vulpin concerns.

The reasons for this choice of crop rotation combine agronomy, management and economics (flax, the region's leading crop, faba beans, economically profitable beet).

Rotation features

Use of companion plants

- Bean for rapeseed (lure effect against flea beetles).

- Barley for wheat and beet.

External OM input

In addition to crop cover and straw residues, there is a contribution of RCW without incorporation (this conserves surface oxygen) after flax, about 10t/ha. This input will take between 2 and 3 years to be completely decomposed (RCW must not be found in the flax slicks). They then sow the wheat directly into the RCW.

This contribution does not have a direct impact on the crop, but it increases the stable OM content with C/N levels below 50, so that it can be degraded into humus. (cf. analyses de sol Celesta lab).

Use of starter fertilizers

Use of starter fertilizer' at sowing to anticipate the lack of mineralization that can occur in SD.'

Use of fermented extracts

Use fermented nettle extracts, comfrey, garlic maceration.'

- Nettle is a silica-rich plant that thickens the cuticle of wheat and beet leaves, making them more resistant to bio-aggressors.

- Garlic is an excellent insect repellent. Flax is a crop often attacked by flea beetles, so after sowing, when the flax is 2-3 cm tall, Antoine and Guillaume apply garlic maceration.

This allows them to stop using insecticides on the farm.

Cover crops

Plant cover crops are used in rotation for several reasons:

- Important nitrogen contribution to the crops that follow (between 20 and 40 units of nitrogen/ha, for example, for the cover crop preceding beet. Faba bean as a rapeseed companion plant can also fix 20 U of nitrogen resituated to the rapeseed at the end of winter, and can even be beneficial to the wheat crop that follows, thanks to the mineralization process), also generating fertilizer savings.

- Substantial addition of biomass (minimum 250 plants per hectare, calculated using the MERCI method in December) after a frost and a pass through the Rolofaca, when the canopy is theoretically in flower. . "Except that in our region, the canopy is quickly in flower and it's still too early to destroy it. The aim is for it to decompose before the spring crop. Herbicides are not normally needed for its destruction" (just for the following crop, to manage ray grass/vulpin).

- Soil drainage thanks to their root structure.

- Break the grass cycle.

- Their cost: Approximately 70€ per ha.

Reducing tillage on industrial crops

Although Guillaume and Antoine are adepts of direct seeding, they recognize that it is a system with its limits: we can hardly do without tillage for crops such as potato, beet, flax" in particular to warm up the soil, level out boar holes, mounds created by moles, and so on.

The guiding principle was to ask what they could do, during the long rotation, to build up the soil more than we deconstruct it after a penalizing crop like beet.

For beet, a few days before planting, "they work the soil to a depth of 3 cm" with a "rolling spade" tool, then "they restructure the soil with a strip-till which allows them to work a 10 cm row every 50 cm, to a depth of 12 cm".

A few days later, they refine the line with a strawberry, which precedes the beet drill.

Fiber flax, which is very sensitive to compaction and requires particularly well-levelled soil, also benefits from shallow tillage. Knowing that these two crops are the ones that destructure the soil the most, Guillaume and Antoine try to space them further apart and lengthen the rotation to give the soil time to rest.

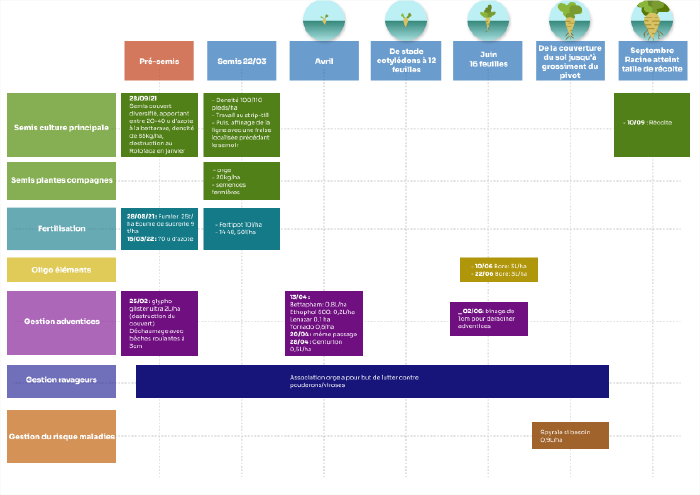

Focus on a culture : Beets

Here we will develop an example of a reduced-tillage technical itinerary for beets.

For the record, the simplified itinerary for beet culture (the lead of the rotation) used by the Chedru family is :

Pre-seeding : Possibility of multi-species cover in August the year before

Ground work: stubble cultivation to level the land and hoeing in June at 1cm

Type of seeder: three passages of strip-till

Sowing date: 03/22

Seeding density: 125 thousand seeds/ha Companion plants: oats/farm barley, 20kg/ha

For beet, a few days before planting, they work the soil to a depth of 3 cm with a rolling spade tool, then restructure the soil with a strip-till, which allows them to work a line of 10 cm every 50 cm, at a depth of 12 cm.

A few days later, they refine the line with a self-built localized tiller, which precedes the beet drill.

Biodiversity focus on the farm

There are twelve beehives on the farm (belonging to the President of the Seine-Maritime Departmental Council), so they want to avoid mortality, a parameter that has motivated the reduction in phytosanitary products and zero insecticides.

"You have to feed them all the time. They feed in spring, when faba beans, peas and colza blossom. Cover crops based on peas, sunflowers and faba beans help them get through the winter".

Focus on autonomy

- Seed self-sufficient crops: Wheat, fababeans (also exchange seeds, e.g. fababeans for sunflower).

- Crops with purchased seed: Beetroot, rapeseed.

- Overall self-sufficiency: Self-build workshop for machinery (especially seeders), straw/manure exchange, dryer and storage area on the farm, branches and green waste brought in by the waste disposal center and neighbors.

Equipment: disc seed drill AND tine seed drill

The farm is well equipped in terms of equipment, because in a very rainy region, the window of opportunity for seeding is quite short. Guillaume and Antoine alternate between two seed drills: one with discs and one with tines:

The tine seeder

Self-built. Total investment is €30,000. Commercially available equipment would cost around €100,000.

- The tool is 6 m wide and has '20 elements spaced 30cm apart.

- 3 depth levels: A single pass can perform 3 different operations (in particular, they have added a micro fertilizer for localized fertilization in the furrow).

- Sowing: Suitable for large and small seeds (cover crops, rapeseed).

- With the aim of "disturbing the soil as little as possible", the tool runs at a maximum speed of 7 km/h.

- Particular attention is also paid to low tire pressure.

- The work rate is 4 ha/h.

- The seed drill is mounted, and weighs 3.5 tons, which means that it requires more power and lift than a semi-mounted machine.

The disc seeder

[Fichier:Semoir à disques chedru.jpg|vignette|Semoir à disques des Chedru]]

- It was purchased secondhand for €25,000.'

- It is used for 'sowing wheat and flax under plant cover (clover or legumes).

- The tractor is equipped with a ballasted Rolofaca (2.8 T for 4.5 m width) to lay down the canopy.

- The discs have a 12 mm opening. They are positioned 15 cm apart, which is ideal for sowing flax, the region's flagship crop.

- Pinches the straw at the bottom of the furrow, greatly disrupting emergence.

RTK self-guidance system - working comfort

- The RTK system costs €15,000 per tractor for plot mapping. It can then be used 'for all tractors.

Other equipment

- Beet drill shared with a neighbor.

- CUMA harvesting equipment.

- Strip-till

Economics

Antoine and Guillaume are lucid about their system: "With ploughing, we might have better yields. But it's the margin and not the turnover that we're looking for".

| Rapeseed | Durum wheat | Beetroot | |

|---|---|---|---|

| Product | 2 812 € | 2 915 € | 3 960 € |

| Seeds | 161 € | 378 € | 288 € |

| Fertilizers | 717 € | 424 € | 382 € |

| Oligos | 15 € | 36 € | 32 € |

| Phytos | 67 € | 99 € | 183 € |

| Mechanization | 53 € | 50 € | 75 € |

| Irrigation | 0 € | 0 € | 0 € |

| Gross margin 2022 | 1 800 € | 1 927 € | 3 000 € |

- Inputs have increased enormously: nitrogen, phosphorus, potash and all the trace elements and phyto products.

- The dryer consumes a lot of energy.

- For fuel: in the accounting documents, you need to know that the services provided by other farmers, Guillaume and Antoine, do not exceed 50 and 60L/ha.

Marketing

Guillaume and Antoine used to deliver everything to storage organizations. Now they "alternate between a few forward sales cooperatives" and a little direct selling. They keep a constant eye on market prices. The most important thing is to know your production costs, and then you can define a sales strategy.

| Culture | Customer |

|---|---|

| Lin | Agylin |

| Cristal Union | Cristal Union |

| Cristal Union | Cristal Union |

| Beans | Cover + trader |

| Peas | Covered + dealer |

| Corn | Direct sale to a farmer |

Storage

They store 100% of their crops thanks to the'adaptation of former livestock buildings present on the farm with :

- Adapted ventilation.

- Flat storage on level platforms.

- A dryer to dry crops that are too wet.

2022 Economic, social and environmental report

- Level of comfort at work, taking into account physical or mental hardship: 8/10

- Economic satisfaction: 10/10

- 'Daily work satisfaction, feeling of being surrounded in one's work: 10/10

- Cooperation with other local players, mutual aid: 7/10

- Living environment: 10/10

- Percentage of Organic matter: 2.8

- Soil coverage (days/year) :340 days

- Tillage index (tilled area x aggressiveness coefficient x depth): 1.2 i(l was calculated on two technical itineraries, rapeseed and beet)

- SIE/SAU : 0.04

- Crop diversity (number of crops in the rotation, excluding cover crops): 6

- EBE/UTH: 194,336 (e)

- EBE/CA (%): 41

- Subsidies/Sales (%): 10

- Annuities/EBIT (%): 34

- Expenses/Sales (%): 70

Working hours are difficult to estimate.

Source: Moyennes régionales Agreste/Rica (Réseau d'Information Comptable Agricole) 2021

Tips for getting started

- Start with simplified seeding and gradually increase OM levels:' "If you don't have good natural porosity and a good level of organic matter, you won't be able to do without tillage. You have to start by creating a soil in the first years of transition. It's a long-term job."

- Surround yourself:' Antoine felt isolated in the experimental approach he embarked upon (at the start there were five of them in the department, and all the organizations in the sector were telling them they were heading straight for disaster). They got a lot of help from Jean-François Aubry and through exchanges on internet forums, but above all through group work. It was very hard to get off the beaten track, to face up to the scrutiny and pressure exerted by other farmers who don't question their model. Antoine is therefore grateful to be part of a group of 15 somewhat original farmers, for whom any idea has the merit of being tried out, and who are constantly open-minded.

- Integrating the agricultural sector into the transition: A group can't change everything on its own either: Sol en Caux has therefore integrated the entire upstream and downstream agricultural sector (cooperatives, storage organizations, technicians, management bodies, etc.).

- When you have a global approach and take care of the soil, you open up exceptional horizons.

Vidéo

Sources

- Visit to the Ferme de Longueuil on 07/11/2023.

- Decompacting a no-till soil, Guillaume Chedru.

- https://www.youtube.com/watch?v=7P-yJtKCLDM Tour de plaine #5: Gestion d'un système grandes cultures pour réduire les charges et protéger le sol] (Youtube - AgroLeague).

- Regional averages Agreste/Rica (Réseau d'Information Comptable Agricole) 2021.

- GisSol.