Chain harrow

The harrow chain harrow is a tool for mechanical weeding in the open field. It is composed of articulated panels to follow the terrain, equipped with long flexible teeth spaced 2 to 3 cm apart.

Operating principle

The flexible teeth vibrate as the tool advances, uprooting and injuring the weeds.

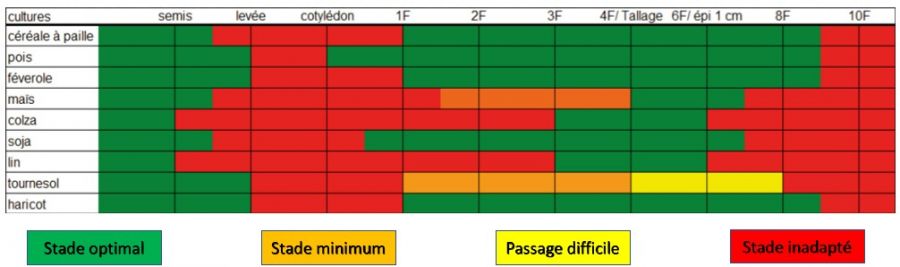

This tool can be used in the open on many crops such as wheat, sunflower, sorghum, corn, barley, soybean, rapeseed, bean, seed bearer....

Mode of action

The chain harrow uproots and covers the aerial parts. It works at about 2 cm depth

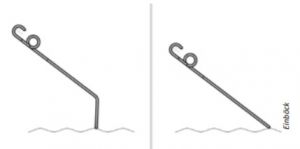

(or even 3-4 cm in raised soil) independently of the crop rows and thus allows weeding over the entire surface. Its flexible teeth vibrate with the tool's advancement and uproot the weeds by vibration and impact. These teeth, spaced 2 to 3 cm apart, can be straight or curved.

Curved teeth offer better aggressiveness than straight teeth but are less suitable for very stony soils. They are mounted on different independent panels that allow good adherence to the terrain and good tracking of its heterogeneities. The diameter and length of the teeth must also be chosen at purchase according to aggressiveness objectives.

Settings and aggressiveness

The aggressiveness of the chain harrow results from the inclination of the teeth and their vibration, itself linked to the tool's forward speed. Settings are delicate because a compromise must be found between good selectivity for the crop in place and good effectiveness on weeds. The working depth is related to the gauge wheels. It should not be too high to avoid lifting weeds.

For more information on settings.

Effectiveness and selectivity according to soil conditions

The chain harrow, like other mechanical weeding tools, requires a drained, leveled, and compacted soil to work effectively. It is preferred on stony soils, as its effectiveness is not impaired there. However, it is ineffective alone on crusted soils because its teeth cannot penetrate the soil. The soil should also not be too cloddy to avoid covering crop seedlings with clods, and there should not be too much plant debris because the chain harrow tends to rake.

Effectiveness against weeds

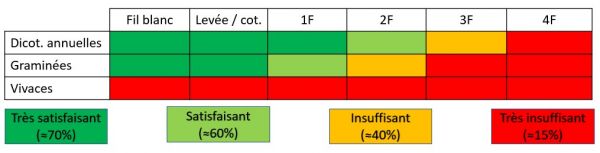

The chain harrow is not very effective on perennials (it can nevertheless weaken field bindweed and hedge bindweed with repeated passes). It is only effective on small weeds (50 to 70% effectiveness according to ACTA, 2011). They must be at the "white filament" stage (germinating), cotyledons or even 2-3 leaves.

Selectivity regarding the crop in place

This tool is generally suitable for all crops but not at all stages of their development. The right time for mechanical weeding is determined among other things by the crop stage. The tool must not weaken the crop in place and should therefore be used at stages where the crop is less sensitive to the tool's work (tillering of cereals, 2-4 leaf stage of other crops). It is still recommended to increase sowing densities by 10% in anticipation of plant losses caused by the tool's passage. At early stages (in raised soil then after the first leaves appear), it is preferable to use the Rotary hoe then the chain harrow which offer better selectivity than the Cultivator. After these early crop stages, the chain harrow will only be effective on new weed seedlings.

Usage ranges

Strengths and weaknesses

Strengths

- Versatile tool

- Wide spectrum of effectiveness

- High work rate

- Lower purchase and operating cost

- Low maintenance

- Usable in windy conditions

- Effective on stony soils

- Weeds in the open field

- Avoids selection of herbicide-resistant herbicides-resistant weeds

- Power 10 to 12 hp/m

Weaknesses

- Ineffective on developed weeds and on perennials

- Requires well-leveled soil preparation

- Low effectiveness in presence of crusted crusting, prefer the Rotary hoe

- Frequent clogging in presence of surface plant debris

- Sometimes delicate settings

Cost per hectare

Equipment + tractor + labor: €9/ha (12 m tool on 200 ha/year).

Selection criteria

| Points to consider | Comments |

|---|---|

| The frame can be mechanically foldable (small widths) or hydraulically foldable (U or portfolio/double effect) | Hydraulic folding has a significant impact on price but is practically essential from 6 m width upwards |

| The adjustment of the teeth attack angle (aggressiveness) can be done manually by a lever or hydraulically from the tractor cab | This criterion particularly affects the price |

| Length of teeth | From 380 mm to 600 mm.

Long teeth in crusted soils risk misalignment |

| Tractor lifting capacity | Ensure sufficient lifting force (weight of a 12 m harrow = up to 2t) |

| Power requirement | 7 hp/meter linear for spring crops (pay attention to tractor track width) and 10-12 hp/meter linear for cereals |

| The diameter of the teeth is generally 6-7 mm, with optional 8 mm teeth | An 8 mm diameter will be too aggressive for spring crops |

| Use on permanent pasture | To be avoided as ineffective and risk of deforming teeth |

| The spacing between 2 teeth represents the soil surface worked by the chain harrow | Important criterion: the smaller this spacing, the larger the soil surface worked |

| Gauge wheels: generally 4 from 9 m width | They ensure good depth consistency of work. Acquiring an additional pair may be interesting for 12 m harrows. |

| Double teeth | Double teeth, removable by pins, have greater fragility over time. |

| Tooth wear: carbide teeth (usually optional) are more durable | Criterion to consider for "abrasive" soils (clay with flint, stones) |

| Spring chain harrow | Allows more demanding work because it offers:

However, this machine is more expensive. |

Different models of plate chain harrows

| Manufacturer | Model | Minimum width | Maximum width | Aggressiveness adjustment | Reference price (for a 12 m plate chain harrow) | Details |

|---|---|---|---|---|---|---|

| Steimer | Natalia | 6 m | 12 m | Manual | Unknown | Detail |

| Agronomic | HE Agronomic | 1 m | 12.5 m | Hydraulic | €20,000 | Detail |

| UNIA | Akcent | 6 m | 12 m | Manual | €10,000 | Detail |

| AGRImarque | Chain harrow | 1.5 m | 12 m | Manual | €13,080 | Detail |

| APV | AS | 3 m | 12 m | Manual or hydraulic | €14,380 | Detail |

| Agrokraft | Tor | 3 m | 12 m | Manual or hydraulic | €13,500 | Detail |

| Agro-Factory II | IZAK | 7.5 m | 12 m | Manual | €10,346 | Detail |

| ETR AVT | HE ETR AVT | 1 m | 14 m | Manual or hydraulic | Unknown | Detail |

| Hatzenbichler | Original harrow | 3 m | 15 m | Manual or hydraulic | €18,000 | Detail |

| Carré | Sarclerse | 1.5 m | 12 m | Manual or hydraulic | €16,400 | Detail |

| Quivogne | HET | 3 m | 12 m | Manual | €15,000 | Detail |

Different models of spring chain harrows

| Manufacturer | Model | Minimum width | Maximum width | Aggressiveness adjustment | Reference price (for a 12 m spring chain harrow) | Details |

|---|---|---|---|---|---|---|

| Agronomic | Agronomic | 1 m | 12.5 m | Hydraulic | €25,000 | Detail |

| APV | Vario | 1.7 m | 12.2 m | Hydraulic | €32,983 | Detail |

| Pöttinger | 9 m | 12.2 m | Hydraulic | €27,000 | Detail | |

| Lemken-Steketee | Precision HE | 3 m | 15 m | Manual and hydraulic | Unknown | Detail |

| Lemken-Steketee | Thulit | 6 m | 12 m | Unknown | €39,900 | Detail |

| ETR AVT | HNG ETR AVT | 1.2 m | 15 m | Hydraulic | €25,000 | Detail |

| Agrifarm | Bio Profi | 3 m | 24 m | Hydraulic | €38,485 | Detail |

| Hatzenbichler | "Original" Air Flow harrow | 1.5 m | 15 m | Manual and hydraulic | Unknown | Detail |

| Carré | Pressius | 1.8 m | 15.4 m | Hydraulic | €47,300 | Detail |

| Horsch | Cura ST | 2.3 m | 24.5 m | Hydraulic | €38,000 | Detail |

For more information on the chain harrow

- The chain harrow - Chamber of Agriculture of Ile de France

- Mechanical weeding: focus on the chain harrow - Chamber of Agriculture of Nouvelle Aquitaine

- The chain harrow - AgroTransfert

- Chain harrow - Arvalis

- Chain harrows descriptive sheet - Chamber of Agriculture Nord-Pas de Calais region

Videos

The chain harrow in market gardening

Article written with the support of:

Sources

- Chain harrow - Arvalis Infos

- Mechanical weeding of field crops - ITAB

- DEPHY-FG-CRAO2019 collection

- https://optimat.org/