Hoeer

Hoeing consists of loosening the superficial soil layer around cultivated plants.

Operating principle

By penetrating the soil, the shares or stars cut the weeds present between the rows. This tool is rather reserved for passes at more advanced stages of the crop and weeds.

The tools are equipped with teeth and shares allowing to work the soil at the desired depth. Wide shares allow shallow soil work that cuts weeds 2 or 3 cm below the soil surface, at the level of their roots, which is enough to destroy them. Indeed, if the weather is dry, no longer supplied with water, they die within a few hours to a few days. If it rains again, some may re-anchor their roots in the soil and continue their development. A second hoeing will be necessary if they are too numerous.

Some tools are adjustable or equipped with parts allowing ridging of the crop row of interest, which allows covering poorly developed weeds on or near the row. This limits the competition these weeds have on the crop of interest.

To preserve the crop in place, it is necessary to keep the tool in the inter-row under penalty of damaging the crop in place. For this, different systems have been implemented.

- On animal traction systems, it is the driver who guides his tool, the precision is low and it is not allowed to work more than 60% of the inter-row width.

- On tractor traction systems, the driver can also guide his tool with the tractor's movement, whether pushed or pulled. Other solutions improve the work done: precision allowing work on 80% of the inter-row and working speed.

- Manual guidance of the hoe offset: a person guides the hoe laterally behind the tractor using a steering wheel or joystick if it is a hydraulic system.

- Automated guidance of the hoe following different markers:

- Following a furrow dug in the soil during sowing

- Row sensors: detect the crop rows by touching them

- Camera that detects the crop rows

- GPS following the path made during sowing previously recorded

Manual guidance requires two operators, one driving the tractor, the other the hoe; reaction time is slow and working speeds limited. The furrow and GPS systems allow intervention at any time, including before crop emergence. The camera system allows following the rows as soon as the crop has emerged but is less effective if there are many weeds. Finally, the row sensor is effective if the crop is tall enough and weeds are poorly developed. In the 2000s, small "autonomous" robotic weeders, such as the Oz robot from the startup Naïo Technologies, appeared on the market, equipped with cameras and infrared vision for market gardening[1].()

Mode of action

The shares of the hoe cut or uproot roots and can bury young weeds by bringing soil back onto the row.

Unlike the harrow and the rotary hoe, the hoe does not work in full width: it weeds the inter-rows of crops planted in rows with spacing more or less large depending on the precision of guidance such as wheat, sunflower, sorghum, corn, barley, soybean, rapeseed, seed producers...

The different hoeing elements (1 per inter-row) are fixed to a central beam but are independent and can be adjusted to different spacings. These elements have one to five working parts, the type of share determines the action on the soil and weeds (shares of vibrocultivator, triangular shares type "goose foot", blades or stars). Increasing the number of parts can lead to uneven effectiveness on different inter-rows.

The working depth is 2 to 10 cm depending on soil type. Deep work can promote the rise of new weed seeds.

Settings and aggressiveness

- Settings are made on the choice of shares, working width in the inter-row, accessories (autoguidance, finger wheels, localized spraying, plant protectors).

- The aggressiveness of the hoe is defined by the rigidity of the teeth on which the shares are fixed: rigid teeth increase penetration into the soil. There are rigid teeth like beet cultivator type, mixed or semi-rigid teeth (most used), and flexible teeth of vibrocultivators. The penetration angle of the share also plays a role in aggressiveness: if it is low, the share tends to be parallel to the soil and performs surface cutting work. If it is high, the share tends to penetrate the soil vertically and in this case the work is deeper, more soil is moved and it can have a favorable action on crusting, but also a rise of new weed seeds.

Finally, the action and aggressiveness are defined by the type of share used:

- The vibrocultivator shares are narrow, facilitate penetration into the soil and result in fairly deep work. Their narrowness does not allow overlapping of the work of the different shares. They often open the soil first to allow better work of flat shares or goose foot shares.

- The triangular shares type "goose foot" work at about 5 cm and allow good penetration into the soil if they are not flat. They can have a ridging action to smother weeds on the row. However, if the crop is fragile and ridging action is not desired, there are half-shares that allow scalping action close to the row without causing ridging or covering. Triangular shares can be flat (and thus parallel to the soil). In this case, their action is close to that of blades.

- The blades are flat and their work is done parallel to the soil. They allow scalping the inter-row over its entire width but require precise driving (front hoeing or on a tool carrier) or a guidance system. Beet blades (Lelièvre blades) have the particularity of working only on one side of the tooth to pass closer to the row.

- Stars can sometimes replace the tooth + share assembly. These star wheels tear out weeds and cover them with soil. Similar in action to the rotary hoe, they act on the crusting and can also be used as ridgers.

Effectiveness and selectivity according to soil conditions

To be effective, the hoe must pass over a drained, leveled, low-stony soil, and not too dry.

Effectiveness against weeds

Unlike the harrow and the rotary hoe, the hoe has an effective action (70 to 100%) on developed weeds (up to 3 to 6 leaves). This tool is therefore suitable for later passes in the crop cycle (from tillering for cereals). However, the hoe is not effective on perennials, and its scalping action can lead to propagation of their rhizomes. One limitation of the hoe is that it is only effective on inter-row weeds. To manage weeds on the row, the crop must be ridged, sometimes using discs or flexible fingers (Kreiss). In all cases, a compromise must be found to cover the row sufficiently (5 cm of soil) without damaging the crop.

Selectivity regarding the crop in place

The hoe is used exclusively on crops sown in rows and is particularly suitable for row crops such as corn, sorghum, sunflower, soybean, lupin, faba bean or rapeseed. Although wide spacings are more appropriate and allow better selectivity on the crop, it is possible to hoe cereals sown in rows with spacings around 17.5 cm if the shares are adapted and if the hoe has a guidance device.

The hoe offers good selectivity for the crop because it only works the inter-row. Using a guidance system (camera, photoelectric cell, sensors or GPS) will allow better precision and prevent the hoeing elements from damaging the crop in place. For good selectivity, the crop must also be sufficiently developed and therefore less vulnerable to the hoe's action. For safety, plant protectors can be placed on the hoe to protect the crop.

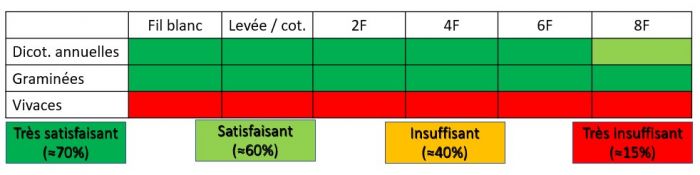

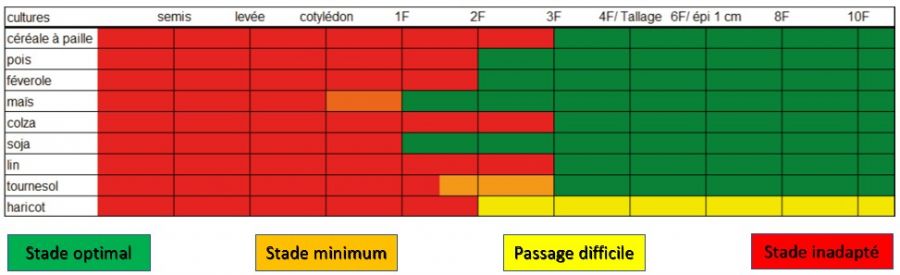

Usage ranges

Strengths and weaknesses

Strengths

- Usable on many row crops

- Wide spectrum of effectiveness even on developed weeds

- Usable in windy weather

- Crusting action on crusting soils

- Avoids selection of herbicide-resistant weeds

- Intervention period spread over the crop cycle

- Autoguidance allows high work rates (3 to 4 ha/h)

Weaknesses

- Requires well-leveled soil

- Tool limited to row crops

- Ineffective in presence of stones or surface residues

- Low work rate without autoguidance

- Cost of autoguidance

Cost per hectare

Equipment + tractor + labor: €18/ha (12-row tool on 200 ha/year).[2]

Selection criteria

| Points of attention | Comments |

|---|---|

| Seeder-hoe compatibility | Preferably choose a hoe with the same number of rows as the seeder |

| Inter-row width varies from 15 cm to 100 cm | Being able to easily move the elements on the beam allows hoeing crops with different inter-row spacings |

| Power requirement | 12-15 hp/linear meter |

| The composition of a hoeing element varies depending on the targeted inter-row: 1 to 5 teeth | Rapid wear of shares in presence of stones |

| Arrangement and spacing of teeth | An overlap between shares will be sought, while ensuring the teeth arrangement facilitates soil evacuation without risk of clogging |

| Individual hydraulic lifting of parallelograms | Significant extra cost |

| Forced penetration of elements | Mechanical or hydraulic |

| Sloping terrain | Different possibilities to correct the hoe trajectory:

|

| Fingers or harrows are offered as options by most manufacturers to allow work on the row | Not essential on corn, interesting on non-ridgable high-value crops |

| Other options |

|

Different models

| Manufacturer | Model | Min width | Min number of rows (for corn) | Max width | Max number of rows (for corn) | Movable elements on beam? | Lifting of hoeing elements? | Reference price (for a mechanical 6-row hoe (corn)) | Details |

|---|---|---|---|---|---|---|---|---|---|

| Bednar | Row-Master RN | 4.8 m | 6 | 9.6 m | 12 | no | no | €15,000 | Details |

| Sfoggia | Thema (hydraulic folding) | 3.3 m | 4 | 6.8 m | 8 | no | no | Unknown | Details |

| Monosem | Multicrop | 3.5 m | 4 | 9 m | 12 | no | yes | €12,000 | Details |

| Monosem | SCD | 3.5 m | 4 | 6.7 m | 8 | no | no | €8,000 | Details |

| Agronomic | Agronomic Hoe | 3 m | 4 | 12.5 m | 8 | yes | yes | €24,000 | Details |

| Agrokraft | Gelio | 3.5 m | 4 | 12.5 m | 16 | yes | yes | Unknown | Details |

| Pöttinger | Flexcare | 4.7 m | 6 | 9.2 m | 12 | yes | yes | Unknown | Details |

| Agri-Structures | Autoguided Hoe | 3 m | 4 | 6 m | 8 | yes | no | Unknown | Details |

| Razol | BMIR (hydraulic folding) | 3.5 m | 4 | 6.6 m | 8 | no | no | €12,000 | Details |

| Samo | Variochop | 3 m | Unknown | 12 m | Unknown | yes | yes | Unknown | Details |

| Dickson Kerner | Variofield | 3 m | 4 | 6.3 m | 8 | yes | no | Unknown | Details |

| Lemken-Steketee | EC weeder | 1.5 m | 2 | 12 m | 16 | yes | yes | Unknown | Details |

| K.U.L.T Kress | Habicht | 1 m | 2 | 6 m | 8 | yes | no | €10,000 | Details |

| Oliver Agro | 2.5 m | 4 | 5 m | 6 | no | no | €23,000 | Details | |

| Badalini | Maia | 2.5 m | 3 | 9 m | 12 | no | no | Unknown | Details |

| Hatzenbichler | A teeth | 3.5 m | 4 | 12 m | 16 | yes | no | Unknown | Details |

| Hatzenbichler | A stars | 3.5 m | 4 | 9 m | 12 | yes | no | Unknown | Details |

| Claydon | Terrablade | 3 m | Unknown | 8 m | Unknown | no | no | €8,000 | Details |

| Franquet | Franquet Hoe | 3 m | 4 | 6 m | 8 | no | no | Unknown | Details |

| Özdöken | ACMK | 4.5 m | 6 | 6 m | 8 | no | no | €9,000 | Details |

| Matermacc | Unica PVI | 3.5 m | 4 | 6.7 m | 8 | no | no | €9,000 | Details |

| Kongskilde | VCO intelli | 6.7 m | 8 | 10 m | 12 | yes | yes | Unknown | Details |

| Kongskilde | VCO | 3.7 m | 4 | 10 m | 12 | yes | yes | €10,000 | Details |

| Carré | Econet mono-beam | 4.5 m | 6 | 10 m | 12 | no | yes | €11,400 | Details |

| Carré | Econet front | 4.5 m | 6 | 6 m | 8 | no | yes | €12,400 | Details |

| Carré | Econet bi-beam | 4.5 m | 6 | 6 m | 8 | yes | yes | €11,700 | Details |

| Carré | Econet cereal | 4 m | Unknown | 6 m | Unknown | no | yes | Unknown | Details |

| Dieter Leibing | Sickle hoe | 3 m | 4 | 10 m | 12 | yes | yes | €12,000 | Details |

| Garford | Robocrop | 1.5 m | 2 | 24 m | 32 | yes | yes | €25,000 | Details |

| Horsch | Transformer VF | 6 m | 8 | 12 m | 16 | yes | yes | Unknown | Details |

| Phenix Agrosystem | Onyx | 3 m | 4 | 12 m | 16 | yes | yes | Unknown | Details |

| Quivogne | Quivogne Hoe | 3.3 m | 4 | 7.5 m | 8 | no | no | €9,150 | Details |

Hoe guidance

Selection criteria

| Points of attention | Comments |

|---|---|

| Manual guidance (steering wheel or joystick) | Requires a 2nd person so interesting for small areas |

| Front guidance (if the tractor is equipped with a front hitch). Some manufacturers offer an adapter between axles or an arm to mount the hoe at the front | Economically advantageous solution |

| Sensors | Only usable on stem crops |

| Trace and guidance skis to allow hoe guidance, it is necessary to make guidance furrows during sowing beforehand | Disadvantage: the trace made at sowing can be erased by the harrow or hoe |

| Camera guidance |

|

| GPS guidance (RTK) | RTK allows straight sowing facilitating subsequent guidance. It allows lifting of hoeing elements for better management of wheel tracks.

RTK on tractor alone is not sufficient for precise hoeing depending on overhang and slope. RTK tracer + hoe systems seem interesting but represent a significant investment. An alternative solution can be to complement tractor-only RTK with sensors and/or camera installation |

Different models

Descriptive tables of several guidance models are available on this page: https://optimat.org/outil/guidage-bineuse/

Appendices

References

- Hoe: choosing the hoeing elements and guidance system well https://www.arvalis-infos.fr/la-bineuse-un-outil-polyvalent-adapte-a-une-large-gamme-de-sols-@/view-9615-arvarticle.html

- RecueilDEPHY-FG-CRAO2019.pdf https://occitanie.chambre-agriculture.fr/fileadmin/user_upload/National/FAL_commun/publications/Occitanie/Agroenvironnement/RecueilDEPHY-FG-CRAO2019.pdf

- Opti'mat: https://optimat.org/

- ↑ Naïo Technologies: the little robot friend of market gardeners

- ↑ Additional information on the Arvalis—Plant Institute website: https://www.arvalis-infos.fr/view-9365-arvarticle.html