Agricultural methanization

Installation of a methanizer for gas production

Installation of a methanizer for gas production

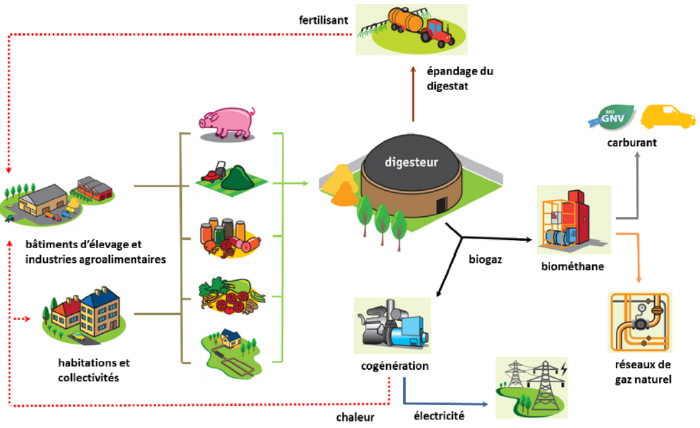

Methanisation is a method of transforming organic matter into energy (biogas) and fertilizer (digestate). It is a technology based on the degradation of organic matter by microorganisms, under controlled conditions and in the absence of oxygen.

Description

Methanisation is a process both innovative and well-known for producing biogas from organic matter, under the action of various bacteria and in the absence of oxygen (anaerobic digestion).

It involves treating waste from agro-food industries or communities (derived from cereals, lawn clippings, sewage sludge, etc.) and valorizing products or by-products from agricultural operations (livestock effluents, crop residues, catch crops, ...) with, ultimately, a return to the soil for the fertilization of crops or grasslands. At the end of this process, the outputs are:

- Biogas composed on average of 55% methane (CH4), 40% carbon dioxide (CO2), and 5% other gases.

- Digestate containing undegraded organic matter (lignin, ...), mineral substances (N, P, K, ...) and water.

Benefits of methanisation

The benefits of this process are widely agreed upon:

- Production of renewable energy valorized as biomethane (injection), electricity and heat (cogeneration) and/or biofuel (bioCNG).

- Valorization of agricultural effluents contributing to the reduction of greenhouse gas (GHG) emissions from livestock.

- Evolution of practices and crop rotations allowing increased nitrogen autonomy (digestate) and soil cover (Energy Valorization Catch Crops (CIVE)).

- Territorial projects combining waste treatment, local energy loops, creation of added value and jobs.

Setting up a methanisation unit

Financial aids

Several organizations can participate in project financing, according to different criteria (see Cour des Comptes 2025):

- ADEME [1] through the “heat fund” and the “circular economy fund”

- Regions

- Europe through the Regional Economic Development Fund (FEDER)

Other aid schemes are implemented for agricultural methanisation (see Cour des Comptes 2025):

- exemptions [2] (according to established criteria) from: property tax on built properties (TFPB), business property tax (CFE) and value-added business tax (CVAE)

- since the “Climate and Resilience” law (2021), a certain part of the cost of connection to natural gas transport or distribution networks is borne by all consumers, under certain conditions

- guarantee-free loan schemes have been created by Bpifrance: “agricultural methanisation” and “injection methanisation”

- the sale of Biogas Production Certificates (CPB) to natural gas suppliers provides a small additional source of income

Methanisation in cogeneration or injection?

Cogeneration allows simultaneous production of electricity and heat from biogas; for this, biogas is burned in an engine.

Injection consists of purifying biogas to transform it into biomethane (more concentrated in methane and thus energy) and then injecting it into the natural gas network (biomethane can also be converted into fuel (BioCNG)). For this type of methanisation, the methanizer must be located near a connection to the natural gas network.

Currently, the number of methaniser installations in cogeneration is low because the energy efficiency of the injection method is higher than that of cogeneration (80% versus 40-55%).

It is possible to change the production mode technically, but this requires administrative procedures that can be restrictive.

Collective, individual or micro-methanisation?

| Collective | Individual | |

|---|---|---|

| Advantages | Non-agricultural partners can reassure banks and bring their expertise | Short transport distances to bring inputs to the methanizer |

| Employees manage methanizer maintenance | Internal valorization of produced energies | |

| The budget can allow investment in a hygienizer | Additional income | |

| Disadvantages | Agreement within the group | Obligation to supply enough inputs |

| Mental load of methanizer maintenance |

Micro-methanisation is a particular individual system intended for organic matter in liquid form (up to 10% solid elements maximum). It is characterized by an installed power below 80 kW electric (electric power of the cogeneration engine), an input quantity between 3000 and 6000 tons of raw materials per year, and self-consumption valorization of biogas in the form of a boiler and sometimes cogeneration.

The system relies on different types of installation:

- a “classic” small volume methanizer

- installation of a gas-tight cover (equipped with a gas meter) on a slurry storage pit; unlike a more “classic” methanisation unit, the digester (thus the slurry pit) is not heated, so the biological reaction is not forced.

Substrate supply for a methanizer is crucial

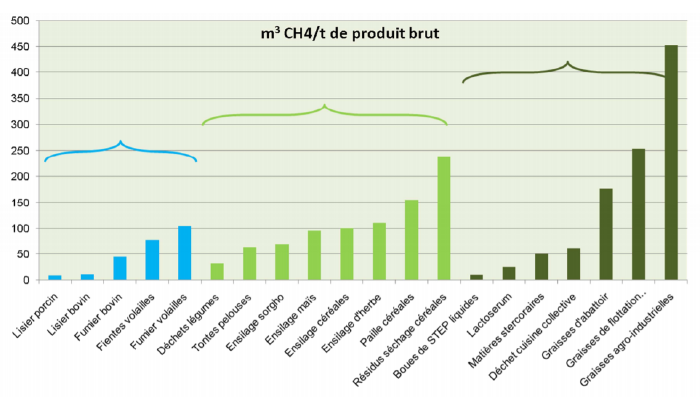

In methanisation projects, supply is fundamental because the choice of organic materials (substrates), each having a methanogenic potential, degradability and specific characteristics, determines biogas production, technology used, equipment sizing, and site profitability.

A wide variety of possible substrates

Organic residues used in the methanisation process are called inputs. Methanisation uses different types of organic substrates, offering an ecological alternative to conventional waste treatment channels. Some sites treat waste from the agro-food industry or sewage treatment plants, others mainly receive agricultural inputs. Mixing inputs of different natures (plant, animal, urban waste, etc.) is common and regulated, to balance the methanisation process by providing different types of nutrients.

The majority of the resource comes from agricultural activity: manure and slurry (called "livestock effluents") and agricultural plant materials (crop silages, straw and small straw, crop residues, silo waste, energy catch crops).

Different technologies

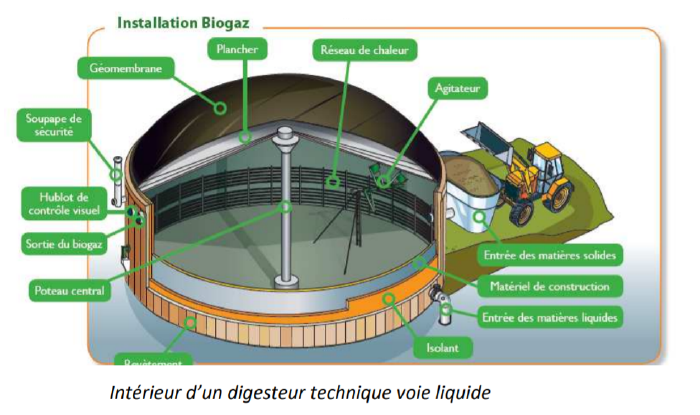

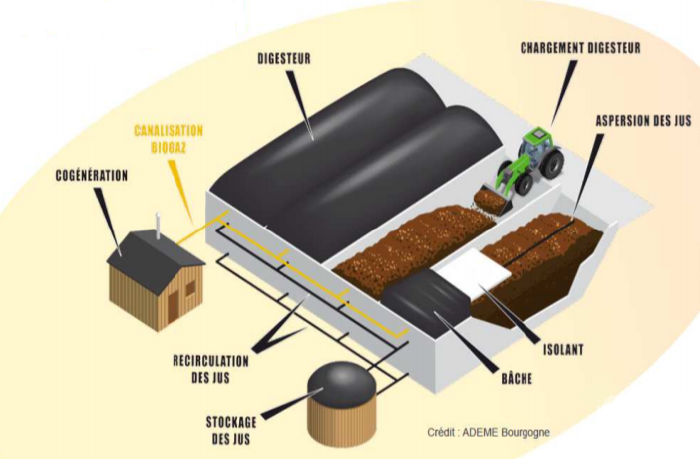

Different methanisation techniques allow valorizing the many organic materials present in our territories. Liquid route, continuous or discontinuous solid route, ...? The choice of technique partly depends on the type of substrate mix obtained.

Liquid route

Dry route

Optimizing methanisation valorization

Analyze the digestate

Knowing the exact composition of the digestate allows refining its integration into a fertilization plan to optimize valorization.

Several indicator panels exist:

- Simple analysis: phosphorus / dry matter / residual moisture / nitrogen Dumas / ammoniacal nitrogen / nitric nitrogen / potassium.

- Complete analysis: residual moisture / potassium / phosphorus / pH / magnesium / dry matter / sodium / total organic carbon / calcium / nitrogen Dumas / ammoniacal nitrogen / nitric nitrogen.

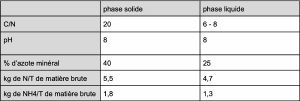

Favor phase separation

In some methanisation units, raw digestates are treated with a phase separation process with:

- A solid phase: stable organic matter form with a high C/N ratio, poorly mineralizable, contributing to improving soil humus content in the long term;

- A liquid phase: organic matter form with a lower C/N ratio, easily mineralizable, providing rapidly assimilable nutrients for crops.

Favoring phase separation allows better control over the use of digestate as fertilizer, depending on the specifics of crop rotation and parcel layout.

Use the right equipment

Spreading liquid digestate can be done with a tankless system directly connected to the storage by a flexible hose (or a box if the field-storage distance is too great), the material is then spread via trailing hoses. Advantages of this technique include:

- the light weight of the system (< 10 t) which reduces soil compaction

- the possibility to spread when crops have already emerged, allowing fractionated applications, timely spreading and limiting leaching

the digestate is deposited at the base of plants which reduces losses by volatilization

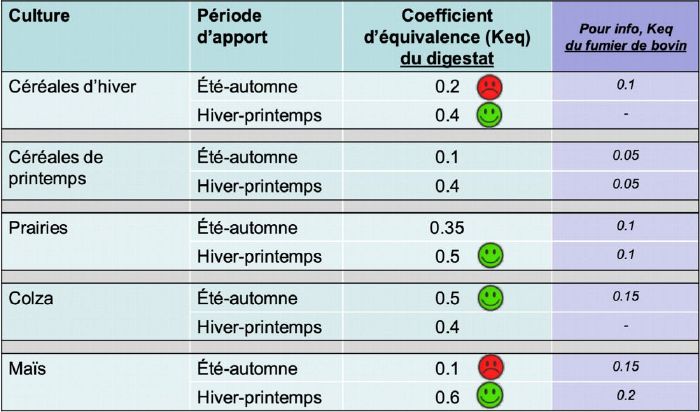

Fertilizing value of digestate

To account for digestate spreading in a fertilization plan, it is important to know its fertilizing value. We focus on its fertilizer equivalence coefficient (Keq), which indicates the portion of nitrogen available to the crop during the growing season. To optimize digestate valorization, a Keq as high as possible is targeted. This rate varies according to crop needs periods.

This equivalence coefficient highlights the crops that best valorize digestate applications, and thus on which applications should be prioritized:

- Mowing grasslands: preferred in late winter (low valorization of ammoniacal nitrogen for autumn applications);

- Rapeseed: in autumn;

- Maize: in late winter;

- Cereals: in late winter;

Example of Keq use for a winter cereal

For an application of 25 m3 of raw digestate at 4.56 kg/t total nitrogen (25 x 4.56 = 115 UN total):

- Application on wheat in autumn: 115 x 0.2 = 23 UN available over the entire wheat cycle;

- Application on wheat in late winter: 115 x 0.4 = 45 UN available over the entire wheat cycle.

⚠️ For cereals, it is better to avoid any autumn application: nitrogen needs of cereals in autumn are limited (5 to 15 UN) and the soil can supply these needs. Nitrogen is poorly valorized and presents risks of ammoniacal nitrogen losses to the atmosphere and nitrate leaching into groundwater.

For autumn applications, preference is given to applications on rapeseed or on cover crops which valorize nitrogen well, only if they have good emergence. The cover crop will return nitrogen to the spring crop which will valorize it in turn.

⚠️ It is essential to incorporate digestate if applied before sowing, to limit ammoniacal nitrogen losses by volatilization.

Recommended applications: 20 to 25 m3, except before rapeseed and on cover crops where 15 to 20 m3 will be applied.

- If incorporation is planned, it should be done immediately after spreading, which greatly limits losses.

- If spreading is done only on the surface, it should be followed by rain, or just before rain, under low wind conditions and temperatures below 15°C.

Maximize biomass production and methanogenic yield

Biomass

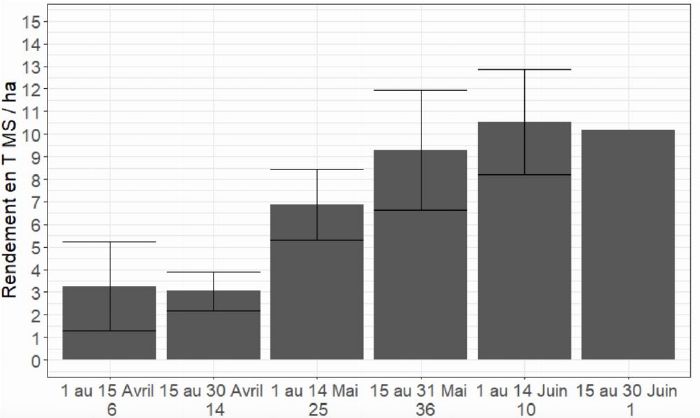

For winter CIVEs, the main challenge is to harvest the CIVE as late as possible without impacting the following food crop.

For staggered harvests from March 20 to April 20, production can double or triple. 20 to 40% of production occurs in the last 15 days.

Adapting the following crop is therefore an essential success factor, as well as the earliness of CIVE sowing date.

Fertilization

- Nitrogen needs of winter CIVEs are concentrated in spring, ensuring the nitrate trap function in autumn. Fertilization levels according to crop sequence and soil supply range from 60 to 100 UN.

- In situations where CIVEs feed methanizers, digestates are good candidates for fertilization. In these cases, digestate application should be positioned before precipitation for winter CIVEs with narrow spacing to avoid losses by volatilization.

- For summer CIVEs with wider spacing, incorporation of digestates at application limits nitrogen losses.

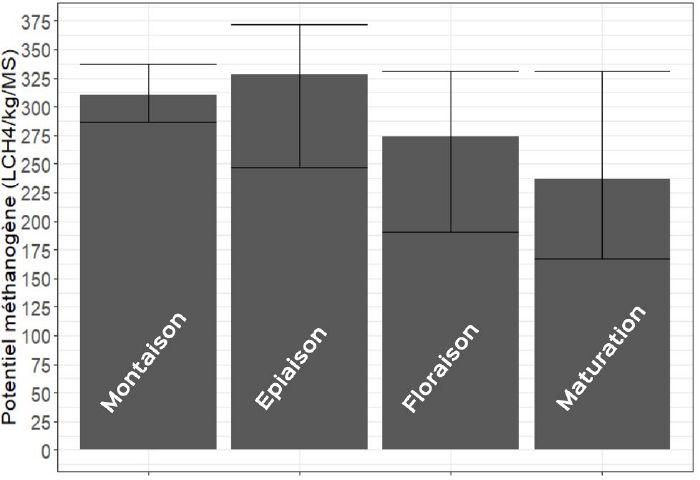

Methanogenic yield

Biomass production correlates with the methanogenic potential of CIVEs, expressed in liters of methane produced per kg of dry matter. Maximum yield occurs around heading, as shown in the graph below from results of experiments of the “Demonstrator Sites Network” project in Hauts-de-France.

Methanogenic yields vary greatly between species. However, when a mixture is established, e.g., grass + legumes, species differences diminish, especially with late harvest.

Maximize nitrogen fixation in CIVEs

For a winter CIVE, grass mixtures (oat, triticale, barley) or grass/legume associations are best suited.

Introducing legumes reduces total biomass production but contributes to system nitrogen autonomy via return to soil of methanisation digestates. A threshold of 20% legumes seems appropriate (common vetch, hairy vetch, faba bean).

Regarding varietal choice, priority criteria are:

- Earliness;

- Biomass productivity;

- Tolerance to some pests, diseases or viruses;

- Non-frost sensitivity (depending on local conditions).

Reduce herbicide costs on CIVEs

Weeding must be adapted to the chosen species and managed in the crop sequence:

- Higher weed pressure than in food crops can be accepted due to immature plant harvest and reduced weed seed set.

- Associations limit weeding options but often ensure soil cover that competes with and suppresses weeds.

The sector

The methanisation sector includes all economic actors involved: farmers, manufacturers, equipment suppliers, consulting firms, financiers, researchers, etc.

Moreover, several public services may be involved in project support or administrative file management at various levels (municipality, department, region, State).

The Chambers of Agriculture support the development of agricultural and territorial methanisation, in the form of individual or collective projects led by farmers. These projects can be developed towards cogeneration, biogas injection into natural gas networks, or biomethane fuel production. The key is to prioritize "tailor-made" and profitable projects, developed and managed by motivated farmers, rooted in territories with strategic partnerships.

The Chambers of Agriculture have strengthened their resources dedicated to agricultural methanisation development, notably with a national network of 50 experts. Today, in most regions, the Chambers of Agriculture support projects at various stages, from emergence to monitoring existing units and capitalizing on references.

Effects of methanisation

Agronomic

Methanisation contributes to agroecological transition in various ways. Agronomic effects vary depending on installation typology: on-farm (integrated into a farm), agricultural collective (carried by several agricultural structures), or territorial (carried by various actors, communities, developers, industrialists, farmers, valorizing waste from a given territory).

Whatever the typology, methanisation ensures the return to soil of organic waste from a territory by spreading digestate, thus entering the virtuous circle of the circular economy.

- Methanisation and nutrient cycle

- Evolution of mineral substances during and after methanisation

- Accessibility of nitrogen in digestate

- Effects of digestates used in agriculture on soils and crops

- Soil humus balance and methanisation

- Fertilizing properties of digestate

- Methanisation and agricultural crops

- Management of energy catch crops

- Biomass production and impact of catch crops on soils and organic matter

- Competition of CIVE with other productions or functions

- Valorization of agricultural co-products

- Storage of co-products before methanisation

- Digestate

- Evolution of organic matter during and after methanisation

Environmental

Agricultural activity is a source of emissions of several greenhouse gases (CO2, CH4, N2O ...), either through direct emissions in the field or indirectly through the consumption of fertilizers or energy. Methanization helps reduce several sources of emissions without changing agricultural operating methods. Emissions specific to the methanization process are low compared to the observed reductions in direct and indirect agricultural emissions.

- Reduction of greenhouse gas emissions from agriculture

- Methane emissions from agriculture

- Waste treatment and circular economy

- Methanization of sewage sludge

- Methanization of biowaste

- Potential impact of digestate spreading

- Odor reduction by methanization

- Digestate and water quality

Socio-economic

Installing a methanization unit is the initiative of an actor or a collective of actors (farmers in particular) generally established in the territory or having strong ties with the territory. This territorial component is fundamental to the success of the project, which will depend on its appropriation by the actors of the territory. This appropriation has a geographical dimension (site choice), a social dimension, and a political dimension: it can rely on the territorial dynamic of energy transition that may exist in the territory.

- Job creation

- Methanization and territory

- Societal appropriation of methanization

- Territorial dynamic of energy transition

- State of methanization in Europe

- The methanization sector

Energy

Methanization allows local energy production in the form of biogas from materials from the territory. It thus contributes to national energy independence by reducing the import of fossil natural gas.

There are different outlets for this energy, which can have several functions for professionals and individuals: production of heat, electricity, or biomethane injected or not into natural gas networks.

This agricultural-origin energy has the advantage of stability for French energy systems (electricity and gas). Indeed, the constant production of biogas makes it a non-intermittent supply source. Finally, biomethane is easily storable in natural gas storage facilities to meet variations in energy consumption.

- Various energy outlets

- Contribution of biogas to the stability of the energy system

- Biogas

Regulation

Methanization, like any economic activity, is subject to various regulations and may be subject to national or international standards.

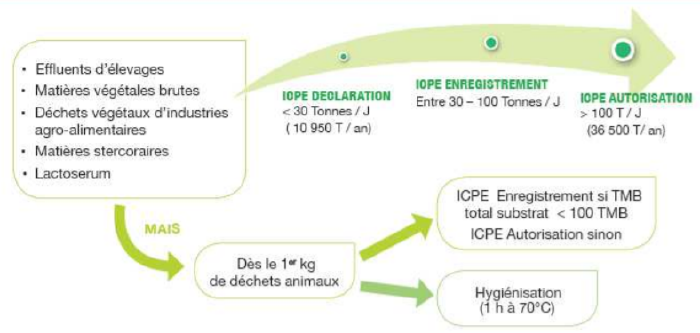

In France, methanization units fall under the ICPE (classified installations for environmental protection), which requires specific procedures at the prefecture before commissioning and during operation. There are different regulations depending on the type of supply to the méthaniseur.

Digestate spreading

Digestates are by default subject to spreading plans, except for certain agricultural digestates meeting one of the specifications Dig'Agri.

International standards are currently under study for methanization units (domestic and non-domestic). European regulations may also apply, notably through directives on renewable energies (RED).

- International standardization on the construction of methanizers

- Hygienization: French regulation

- Digestate valorization in France: regulatory aspects

- Spreading plan and methanization digestates

Digestate spreading is authorized in organic farming, even if the inputs come from conventional farming, provided that the digestate does not come from industrial livestock and is not spread on the edible parts of the plant.

Crops used for biogas production

According to decree n°2022-1120 of August 4, 2022[3], the feedstock used at the input of methanizers cannot be composed of more than 15% (in gross tonnage) of main crops. A crop is considered a main crop if it meets at least one of these conditions:

- it is the only crop harvested on a plot during a calendar year

- it is a crop declared as the main crop in an aid application under a CAP support scheme

- it is a crop harvested on a plot for which no aid application under a CAP support scheme was made for the harvest year

- it is a crop present on June 1st, or, if applicable, on another date between June 1st and June 15th (date defined by the State representative in the department, considering climatic specificities and cultural practices)

- it is a perennial crop (mentioned in article R. 411-9-11-1 of the rural and maritime fishing code) or it is a crop grown on a plot in which a perennial plant is implanted

Digester heating

Energy consumption of biomethane injection sites is regulated [4] by:

- the decree of November 23, 2011 (for contracts signed before November 24, 2020)

- the decree of November 23, 2020 (for contracts signed from November 25, 2020)

These texts define the purchase tariffs for biomethane and require methanization units to use their own energy to heat the digester, it is then possible:

- to use the energy from the biogas produced by the installation

- to recover waste heat from the system

- to recover waste heat from equipment installed on the methanization site, if biogas production is from: sludge, fats, or organic liquids from urban wastewater treatment.

Hygienization chain heating

If hygienization takes place upstream of the digester, it is not part of the methanization scope and is therefore subject to no constraints on the type of energy used for heating; however, if it takes place downstream of the digester, it is not separated from the methanization scope, so heating cannot be done using fossil energy.

Find a methanization unit

ATEE has set up a map of methanization units in France, you can consult it here.

A controversial practice

Many concerns arise when talking about methanization. For example, the fact that plots are specially dedicated to crops to feed the methanizer and no longer for food crops (human or animal).

Among the most often cited nuisances is odor. When sites are near dwellings, residents complain.

The quality of the spread digestate is also a source of concern. If "hygienization" is insufficient, this mixture may contain bacteria that will then infiltrate soils or even groundwater. It may also contain heavy metals and other harmful pollutant residues.

Finally, these installations sometimes have leaks. Methane being a greenhouse gas, leaks could reduce or even cancel the ecological benefit of this process.

Further reading

- Association of Methanizing Farmers of France

- Study and develop your project

- Biogas - Ministry of Ecological Transition

- Methanization feedback - Ambitions Biogas 2023 - Chambers of Agriculture Auvergne-Rhône-Alpes

Sources

- Agricultural methanization - Chambers of Agriculture France

- AgroLeague. 6 keys to better valorize your methanization. https://www.agro-league.com/blog/6-cles-de-reflexion-pour-valoriser-au-mieux-sa-methanisation

- ATEE. Methanization and biogas. https://atee.fr/energies-renouvelables/club-biogaz/methanisation-et-biogaz

- InfoMétha

- Methanization: energy by the territory for the territory - Auvergne Rhône-Alpes Energy Environment

- Chamber of Agriculture of Normandy. Micromethanization. [14/11/2025]. https://normandie.chambres-agriculture.fr/sinformer/rechercher-innover/bioeconomie/la-methanisation/la-micromethanisation#c1032914

- GRDF. What choice between injection and cogeneration: synergies, advantages, profitability. [14/11/2025]. https://projet-methanisation.grdf.fr/la-methanisation/la-methanisation-et-les-energies-renouvelables/les-synergies-entre-cogeneration-et-injection

Cette technique s'applique aux cultures suivantes

La technique permet de favoriser la présence des auxiliaires et bioagresseurs suivants

Cette technique utilise le matériel suivants

- ↑ ADEME. Financing. [14/11/2025]. https://www.ademe.fr/nos-missions/financement/

- ↑ Public Finances. Business property tax - Exempt persons and activities - Permanent statutory exemptions - Agricultural methanisation activity. [14/11/2025]. https://bofip.impots.gouv.fr/bofip/10598-PGP.html/identifiant%3DBOI-IF-CFE-10-30-10-25-20190626?utm_source=chatgpt.com

- ↑ Légifrance. 2022. Decree n° 2022-1120 of August 4, 2022 relating to crops used for biogas and biofuel production. [14/11/2025]. https://www.legifrance.gouv.fr/jorf/id/JORFTEXT000046144291

- ↑ AILE. 2021. Guide for implementing hygienization in methanization. [17/11/2025].https://projet-methanisation.grdf.fr/cms-assets/2021/09/GUIDE-HYGIENISATION-VF-sept21.pdf