Packaging and Storage of Vegetables

There is a tendency to focus too much, whether physically or economically, on the production activity alone, yet it is not the only one demanding a lot of time and involvement. Due to lack of consideration, the harvesting, logistics, and sales positions can become real black holes, especially in terms of working time, which is why they must be integrated into the overall farm strategy.

Packaging and preservation : a key logistical point for the success of the market gardening operation

Washing

Washing is the unpleasant and time-consuming task par excellence. Yet it is essential for the presentation of vegetables, so it is important to optimize it to save time while limiting water expenses. To do this, task distribution among different stations is necessary :

- Washing/brushing root vegetables

- Washing bunches

- Packaging endive roots and breaking chicory heads,

- Trimming

- …

Each must have its own space in a dedicated washing area. For this to be optimal, one must not forget to consider the presence of a water inlet and outlet, access to 380V outlets, proper station dimensions, waste management, supply of the lines, and boxing after cleaning.

Towards the finished product

Vegetable preparation indeed follows a long series of steps from harvest to sale : vegetables come out of the field, are stored or packaged, leave storage, go through the preparation line, are packaged, cleaned, and stored again before being shipped.

Logistics on the farm is therefore very important; to ensure everything runs smoothly, it is necessary to set up : a central order-taking unit, transport and storage-packaging tools, a weighing, packaging, and labeling line, packaging stocks, waste management, as well as a loading dock or ramp.

Vegetable storage conditions

Properly storing vegetables offers multiple advantages such as improved quality of the production, time and labor savings, as well as the possibility to spread out sales, especially to maintain diversity in the vegetable offer.

Each vegetable evolves differently after harvest. Its storage potential is determined by the characteristics

specific to its species and variety, notably its respiration rate, as well as by the cultivation and harvest conditions. Conversely, each vegetable requires a different storage method and it is important to seek to provide optimal conditions that do not vary, i.e., the best combination of temperature (°C) and humidity (H%), in the storage space allocated to it.

Tips

- Store species with a short shelf life in an easily accessible place to prioritize their sale.

- To avoid condensation, limit the difference between storage temperature and temperature at exit to 7-8°C.

Precautionary measures before storage

| During cultivation : | At harvest : | Pre-conditioning vegetables : |

|---|---|---|

|

|

|

What type of storage?

In the field

On non-hydromorphic plots :

Leeks, cabbages, carrots, radish, turnip, rutabaga, parsnip (preferably for the latter). Harvest as needed, protecting the crop with thermal covers depending on climatic conditions.

Practical and no investment.

Difficult management of frost and pests.

Space occupation.

Vegetables continue to grow (radishes, turnips) and possibly hollow out.

In dug or above-ground silo

Carrot, black radish, turnip, rutabaga, celeriac, beetroot.

Micro-perforated soil nets or bags in dug pits : drained soil covered with sand. Provide water drainage at the bottom. Cover the bottom with dry ferns to deter rodents. Cover vegetables with soil.

Economical

Harvest is often done the day or the day before sale, in which case a cool or temperate room and moisture protection suffice, even if not always optimal in summer. But many vegetables cannot remain outside indefinitely, exposed to weather; for this, it is necessary to provide more ideal storage conditions.

Storage in a room

Beware of cohabitation as some vegetables produce ethylene (onions, …), a natural hormone accelerating ripening and aging of fruits and vegetables sensitive to it (carrot, cabbage, leafy vegetables, apples, etc.).

In cold room

Regulated according to each species' needs, it is humid and ventilated. Ideally : leafy vegetables, strawberry and small fruits, fennel, endive, zucchini and cabbages. Possible : celeriac, radish and turnip, carrot

Allows longer preservation of storage vegetables.

Not well suited for small diversified surfaces as it is a significant investment.

The refrigeration unit tends to dry out vegetables.

Self-built cold room

To reduce costs, it is possible to build a simple insulated and ventilated room before adding a refrigeration unit :

- Used sandwich panels (10-15 €/m²)

- Door (possible to recover doors from cold rooms in supermarkets replacing their equipment or closing)

- Refrigeration unit (from €3,000 new + installation cost)

A vegetable always stores better unwashed. A root vegetable stores better in darkness.

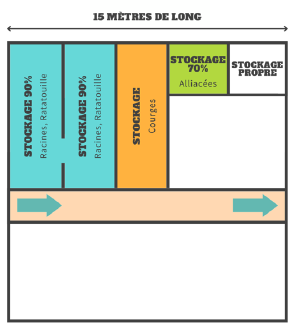

In temperate room

Allows aeration for vegetables not necessarily needing very low temperatures.

Isolated ventilated humid room (RH 90%) : eggplant, tomato, bell pepper, carrot, beetroot, turnip, potato, celeriac, bean, melon, cucumber, leek, rutabaga. Manage around 5-10°C in winter, 15°C in summer.

Essential to install : the cornerstone of storage.

Isolated ventilated dry room (RH 70%, 5-8°C) : onion, garlic, shallot.

Difficult to keep vegetables beyond February.

May require a dehumidifier.

A well-aired ventilated room such as a porch or a very airy attic may suffice.

Isolated ventilated dry and heated room (RH 75%, 12°C) :squashes, exotic vegetables.

It is possible to place squashes in crates or pallets, but also on shelves set up in the room, to avoid the accumulation of weight from stacked squashes.

Heating is often necessary.

Preventive measures during storage

Separate vegetables by group

- according to temperature and humidity conditions

- according to odor and ethylene emission

Sort and check stock health

- do not hesitate to discard damaged vegetables

- ensure easy access to all crates and pallets

Prevent sprouting

- keep onions, potatoes, carrots… in the dark

- possibility to use anti-sprouting peppermint essential oil for potatoes

How to properly organize storage?

The importance of the market gardening building

The market gardening building is a construction or set of constructions that groups storage, washing, sorting, and packaging stations following the logistics of flows. Designing and fitting out the building accordingly allows to ensure better management of harvests and orders, saving time and energy which also has economic repercussions. It is difficult to invest heavily from the start, so it is possible to use existing buildings and gradually fit them out, always keeping these ergonomic questions in mind. Each station must be considered : estimating needs and arranging space. But it is also about designing a system where everything flows : the “forward flow” (vegetables enter from one side and exit from the other) must prevail to avoid tiring back-and-forth and time loss. It is necessary to provide :

- A concrete area : facilitates transport by pallet truck. A loading dock at truck height can also be considered. Note, its installation requires a significant financial investment.

- Homogeneous pallets and/or small-sized pallets. Ventilation must be well thought out and avoid piles over one meter high.

- Démarrer en maraîchage sol vivant

- Le cycle de la fertilité des sols

- Les vers de terre dans l'écosystème sol

- Diagnostic de son sol

- Stratégie de gestion de la fertilité

- Réaliser son bilan humique

- Gérer l'enherbement en maraîchage sol vivant

- Gestion des maladies et des ravageurs en maraîchage

- Conditionnement et conservation des légumes

- Commercialisation et transformation en maraîchage

- Produire ses propres semences

- L’installation en MSV

- Conversion en MSV

- Jardin amateur

- Verger maraîcher

- Avoir un atelier poules pondeuses

- Introduction aux itinéraires techniques

- Conseils de maraîchers sol vivant