Mechanical Weeding

Weed management using agricultural tools (tined weeder, rotary hoe...)

Weed management using agricultural tools (tined weeder, rotary hoe...)

Solutions to combat weeds existed long before the arrival of plant protection products. They were preventive (soil tillage, crop rotation, or mulching) or curative (manual weeding, mechanical weeding for some crops that are hoed, etc.). After World War II, herbicides made weeding more effective and faster. Their massive use now shows its limits. Mechanical weeding can be one of the solutions to reduce the risks associated with the use of chemical methods.

Principle

The control of weeds without herbicides primarily involves prevention, with mechanical actions as a complement (alone, their effectiveness is limited).

It is important to remember that the strategies of herbicide-free cropping systems rely on two essential notions:

- Regular observation of fields and knowledge of the weed flora and the biology of the species composing it are the basis of any management strategy implemented by the farmer.

- The goal is weed control, not elimination. In other words, tolerance to weeds is sought, allowing them to be present in the fields without impacting the production of the crops in place or to come. Some even see advantages, as they contribute to increasing biodiversity, supporting the development of beneficial fauna.

Why mechanically weed?

In recent years, the withdrawal of active substances has accelerated without other solutions being proposed. This has sometimes led to technical dead ends. Complementary or not to chemical weeding, mechanical weeding can provide a more cost-effective and efficient solution. Replacing some treatments with mechanical tool passes anticipates regulatory changes.

Using mechanical weeding reduces the impact of active substances on the environment and prevents water pollution. In pre-emergence, it limits the use of root herbicides, considered the most harmful and likely to leach into groundwater.

Mechanical weeding is not only useful for combating weeds; it also has recognized agronomic benefits. Depending on the equipment and conditions at the time of intervention, the passage of a tool can limit runoff by breaking the crust, aerate and level the soil, reduce water evaporation, position fertilizers, and stimulate soil microbial life and organic matter mineralization.

According to some authors, two to three hoeings could gain twenty units of nitrogen, or more[1]. The passage of mechanical tools also reduces soil water loss by disrupting evaporation in the top centimeters of soil.

Thanks to new technologies, especially guidance systems, the use and performance of mechanical weeding tools are now optimized, capable of adapting to many crops and situations. These innovative systems improve precision and working speed.

Tools

The tined weeder

The tined weeder works at about 2 cm depth (and up to 4 cm in pre-emergence) independently of crop rows, allowing weeding over the entire surface. Its flexible tines vibrate as the tool advances and uproot weeds by tearing them out through vibration and impact.

These tines, spaced 2 to 3 cm apart, can be straight or curved. Curved tines offer better aggressiveness than straight ones but are less suitable for very stony soils. They are mounted on different independent panels that ensure good ground adherence and follow soil heterogeneities well.

There are many adjustments: forward speed, working depth, tine inclination, and especially the pressure applied on them.

It can be used in pre-emergence, then from the 2-3 leaf stage and quite late in the season without too much risk. Its impact is effective on very young weeds up to the 1 to 2 leaf stage.

Intervention should be on a drained, leveled, and compacted soil to ensure good work. If the soil is not clean, there is a risk of clogging the tool. Its effectiveness is limited on crusted soil.

The rotary hoe

The rotary hoe works at about 2 cm depth independently of crop rows, allowing weeding over the entire surface. It is equipped with spoon-shaped wheels at the ends that dig, loosen, uproot, and then throw the weeds.

The tool has high penetration power, making it effective on crusted soil. It can also serve as a crust breaker.

It is recommended to intervene on weeds between germination and cotyledon stages.

There are few adjustments possible: forward speed, pressure on working elements, depth.

It is difficult to use on stony soil.

The hoe

The shares of the hoe cut or loosen roots and can bury young weeds by bringing soil onto the row. It weeds the inter-rows of line crops with spacing more or less wide depending on guidance accuracy.

The different hoeing elements (one per inter-row) are fixed to a central beam but are independent and can be adjusted to different spacings. These elements have one to five working parts, the type of share determining the action on soil and weeds.

In cereals, guidance is practically indispensable because row spacing is very narrow and damage to the crop can be significant if the machine does not stay in the right place. Guidance can be mechanical (marker wheel) or electronic (GPS, camera). It is also possible to mount the tool on the front linkage for more precision.

Hoeing is not recommended at crop emergence but rather for late passes at least until the 1-node stage. Good effectiveness on weeds even beyond the 2-3 leaf stage.

Several adjustments: working depth, pressure applied on each element.

Tool choice

Mechanical weeding can be implemented using a range of tools. Some are complementary, others have similar actions. The perfect and versatile tool does not yet exist. The choice of mechanical weeding tools depends on crops, their stages, soil type, and also weeds[1].

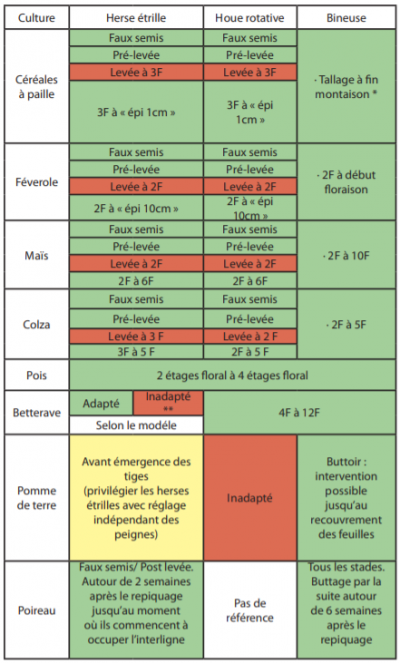

According to crop stage

| Tined weeder | Rotary hoe | Hoe | |

|---|---|---|---|

| Seeding densities | Increase seeding densities by 10% in anticipation of plant losses due to tool passes | ||

| Row spacing | No adaptations necessary | Spacing must be regular, straight, and adapted to the hoe used | |

| Guidance/plant protection system | Not necessary | Strongly recommended | |

| Targeted crops | Usable on all crops | Suitable for row crops | |

| Pre-emergence weeding | No crop damage | High risk of crop damage | |

| Post-emergence weeding | No crop damage (but effective only if weeds are at young stages) | Little crop damage | |

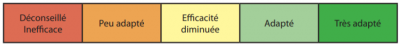

According to soil type

For these 3 tools, a leveled, compacted soil without large plant debris is necessary[1]

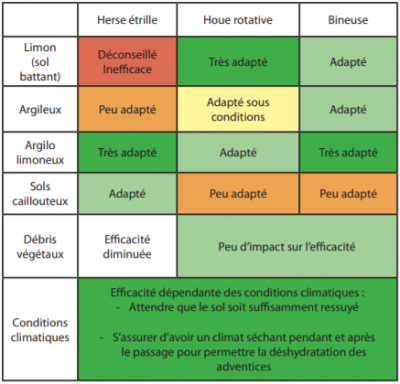

According to weed flora

L=leaf

The tined weeder and rotary hoe allow weeding over the entire surface. The hoe is effective on the inter-row (possibility of action on the row by flexible fingers or ridging).

The roto-tined weeder, the new mechanical weeding tool

The roto-tined weeder is a recent tool, halfway between the tined weeder and the rotary hoe. It consists of discs with round teeth of a diameter equivalent to that of a tined weeder. However, each disc has an attack angle similar to the discs of a cultivator. The entire width of the tool is worked because the discs slightly overlap.

The action of the teeth and the angle of the discs lift a thin layer of soil and thus destroy weeds by uprooting or covering.

It is effective on very young weeds, but also up to the 2-3 leaf stage on dicotyledons.

Several adjustments: machine horizontality, working depth, pressure applied on elements, and forward speed.

Since there is no raking effect, there is no clogging due to residues on the field surface. However, the soil must be well leveled and have received a fairly fine preparation.

Including mechanical weeding in an agronomic strategy

Under certain conditions, mechanical weeding is not as effective as chemical weeding: to avoid field contamination, the cropping system as a whole must be reviewed to try to reduce the seed bank. Lengthening rotations with alternating spring and autumn crops improves the effectiveness of mechanical weeding. Alternating ploughing/no-till and repeated stubble cultivation in summer depletes seed stocks of certain species, especially grasses.

Reconciling weather and mechanical weeding

For passes in cereals, for example, if climatic conditions allow a "blind" pass in autumn, effectiveness will be increased. Then, at the end of winter, as soon as the soil is sufficiently drained, mechanical weeding must be resumed. Two to three days without rain are needed to avoid re-rooting of seedlings. Conversely, if conditions are too dry at the time of the pass, the risk of cutting crop roots increases.

Limits of mechanical weeding

- For some weeds, intervention must occur at a very precise stage, requiring favorable climatic conditions at that time to allow tool passage.

- Passing a mechanical tool in the early stages of a sown crop carries a risk of uprooting or injuring young seedlings because their rooting is shallow.

- Passing a hoe can amplify the phenomenon of vegetative propagation.

Techniques to master

Each intervention condition (crop stage, soil texture, moisture conditions, etc.) requires an adapted tool (blades, tines, harrows..., full or inter-row...), which demands good mastery of these techniques.

Indicative costs

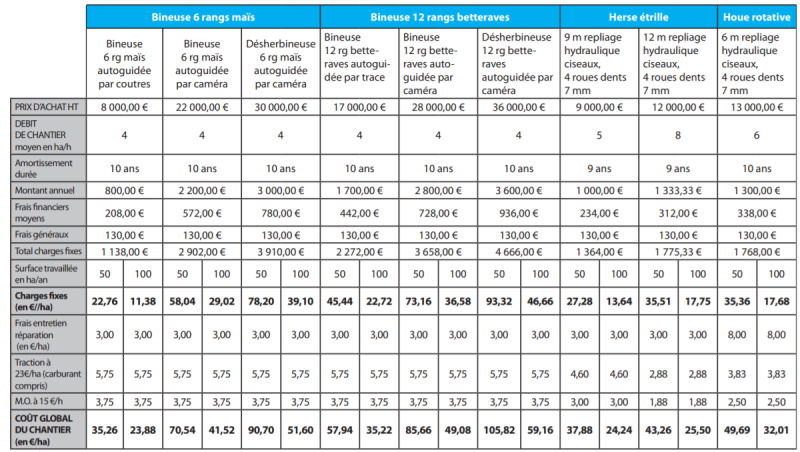

Cost of one mechanical weeding pass[1]:

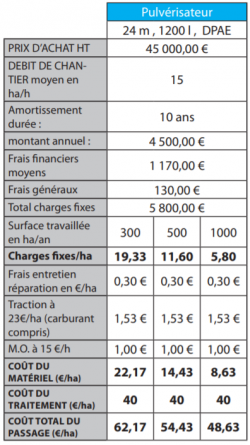

For comparison, cost of one sprayer pass with an herbicide at €40/ha (including filling and rinsing time):

Sources

- Mechanical Weeding - La France Agricole

- Reduce and improve the use of plant protection products - Ecophyto

- Mechanical Weeding in Arable Crops - ITAB Asso

- Mechanical Weeding: Adapting the Tool to the Farm Context - Arvalis-infos