Collecting Straw Chaff During Harvest

Fine straw is plant residue rejected by the combine harvester during grain cleaning at harvest:

- It consists of pieces of straw, the grain husk and weed seeds.

- For cereals, approximately 1 to 2.5 t/ha of fine straw can be expected.

Description

Fine straw is composed of the glumes and paleas of the grains, straw debris, stems and weeds seeds that are at the height of the cutting bar at harvest. It is discharged at the rear of the upper sieve during grain cleaning by the combine harvester. While it is usually returned to the soil, this technique aims to recover the fine straw.

Benefits

Reduction of weed pressure

The primary benefit is to reduce medium-term pressure from certain weeds and regrowth by limiting reseeding of the harvested field.

Limiting reseeding of the field

Exporting the weed seeds contained in the fine straw helps to reduce the enrichment of the existing seed bank and limit recontamination by regrowth (small grains or broken grains). This concerns upright weeds, whose seeds differ in size from the crop and are not already dispersed at harvest.

The effect on field contamination is particularly visible after a few years (2-3 years), especially if the weeds have a short germination capacity.

Arvalis trials

A trial conducted by Arvalis from 2014-2018, on a no-till plot with a succession of 4 winter straw cereals, demonstrated a significant effect of this practice on weed pressure, allowing a 75% reduction in ryegrass density after the 3rd season compared to a treatment without fine straw harvesting:

- This trial was conducted on a no-till plot with high presence of ryegrass resistant (>40 ryegrass/m2 at harvest) and compared a "fine straw recovered and exported" treatment with a "fine straw scattered in the field" treatment.

- In the first year, the technique allowed to recover 70% of ryegrass seeds that had not fallen to the ground before harvest. Little short-term effect on weed cover was observed due to the seed bank already present in the soil.

- However, a 40% reduction in ryegrass pressure was observed the following year and a 20% yield increase after 3 years, all other factors being equal.

- Visible effects are therefore more medium to long term.

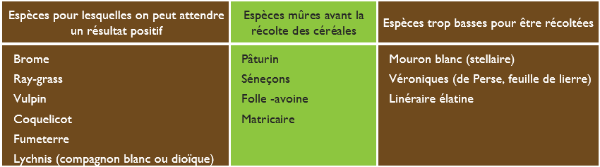

INRA Grignon also reports 70% efficacy on black-grass, brome, fumitory and poppy. However, exporting fine straw, while limiting weed development, alone does not stop it. It should be considered as a lever within a broader weed management strategy to reduce herbicide use, for example by diversifying sowing periods and introduced crops and by using mechanical soil work to bury seeds (ploughing, stubble cultivation) and destroy seedlings by stimulating their emergence (ploughing, false seedbeds).

In the case of a heavily infested field, it is recommended to clean the combine harvester after harvest to limit contamination of other fields and to harvest the most infested fields last.

Valorization as a co-product

The amount of fine straw recovered depends on humidity conditions at harvest (risk of clogging in wet conditions), the recovery device, the crop, its yield and the machine settings. It can reach up to 30% of the amount of straw harvested (see CUMA network trial results in Normandy and Pays de Loire from page 26), averaging 1 to 2 t/ha.

When exported, fine straw constitutes an additional co-product that can be valorized as:

- Livestock farming:

- In an agricultural Methanization project, combustion for boiler: fine straw has good energy production potential.

Comparison of cumulative methane production in a digester between different fresh materials (source: CDER, 2009)

- For composting and soil return: During the composting fermentation phase, the temperature rise will destroy the germination capacity of weed seeds. It is considered that maintaining temperatures above 65-70°C in the compost pile kills the germination ability of weed seeds.

The RMT Biomass & Territory offers a comprehensive summary of possible valorization methods and associated logistical constraints and the manufacturer Thierart a detailed quantified valorization pathways (from page 22).

Reduction of disease and slug pressure

This technique helps reduce damage from slugs or diseases (e.g. fusarium head blight) by reducing regrowth of the previous crop.

Tools, recovery devices

It should be noted that the recovery device chosen for fine straw can condition the valorization to be made (see page 73): integration into the windrow will not allow fine straw to be valorized alone, as it will be used mixed (In the case of valorization as bedding in livestock, it is necessary to compost the manure to destroy the germination capacity of weeds before returning to the field).

Several devices allow recovery of fine straw:

- Adaptable "turbine" type system: deposits fine straw on the top of the windrow via an adjustable chute. Straw and fine straw are thus mixed and recovered during baling. See detailed technical sheet. (adaptable to all combine harvester types).

- Adaptable "box" type system: This system allows to separate fine straw and leave it at the field edge, for export purposes. See detailed technical sheet

- Integrated system: part of factory assembly or original combine harvester equipment (see technical details from page 8), directs fine straw into the windrow. It cannot be exported alone and there is a high risk of soil deposition.

It should be noted that the "turbine" device recovers and exports the most weed seeds. By placing fine straw on the windrow, it limits losses by reducing contact between fine straw and soil. The recovery rate of fine straw is never 100%.

Economic criteria

Operating costs: Decreasing

Operating costs: Decreasing

Additional fuel consumption for the recovery device is very low compared to the total combine harvester consumption (14 hp required to power the hopper). Additional baling work may be needed to condition fine straw deposited at field edges.

Input costs: Decreasing

Input costs: Decreasing

A herbicide cost saving of 20 to 30 €/ha is observed in the medium term.

Mechanization costs: Increasing

Mechanization costs: Increasing

The purchase cost of the device varies:

- Type "turbine" : from €8,000 to €10,000;

- Type "box" : from €30,000 to €40,000;

- The integrated model is included in the combine harvester purchase price.

Depending on existing equipment on the farm, specific equipment for baling (special pick-up on the baler for collection) may be necessary. A ETA (custom work contractor) may also be used.

Margin: Increasing

Margin: Increasing

Among 18 surveyed farmers, 11 report economic interest in recovering fine straw. Although it requires investment in equipment and additional work time, this is offset by increased biomass valorized per hectare and herbicide savings. The effect on margin (crop/rotation) is positive.

Application of the technique

All crops: Generalization sometimes difficult

All crops: Generalization sometimes difficult

Fine straw recovery can be done on many crops: cereal straw, rapeseed, pea, sunflower, faba bean, lupin, maize, ryegrass. Device efficiency varies by crop:

- The "turbine" and "box" types are well suited for cereal straw;

- The "box" type is generally better suited for rapeseed because the windrow is limited and straw often not harvested.

All soil types: Easily generalizable

All soil types: Easily generalizable

Presence of stones in fields may limit valorization projects. For Methanization or bedding use, stones should be avoided during conditioning, which can occur during baling of fine straw.

Complementary techniques

- Perform false seedbeds during intercrop

- Distribute ploughing in the rotation

- Grow diverse species in the rotation

- Clean soil or harvest tools

- Grow species with varied sowing periods

Sources

Recovering fine straw during harvest, GECO

Recovering fine straw, AgroLeague

Further reading

- Fine straw harvest: an additional lever for medium-term weed management, Metais P., Brun D, ARVALIS-Plant Institute, Press article, 2019

- Fine straw recovery: Technical day, Foucault B, Fremont F., Fortino G., Viel L., CUMA Lower Normandy; CUMA West, Professional report, 2015

- Technical sheet: fine straw recovery box, Minette S. (Regional Chamber of Agriculture of Poitou-Charentes), Regional Chamber of Agriculture of Poitou-Charentes, INRA, RMT innovative cropping systems, Technical brochure, 2010

- Technical sheet: "turbo straw" fine straw recovery, Minette S. (Regional Chamber of Agriculture of New Aquitaine), Regional Chamber of Agriculture of New Aquitaine, INRA, RMT innovative cropping systems, Technical brochure, 2011

- Video: No-till and fine straw, a profitable and planet-friendly duo, ordimania, Multimedia, 2008

- Video: Information day on fine straw and valorization in poultry bedding, ordimania, Multimedia, 2010, Presentation by Thiérart company, Doux group for valorization of fine straw as poultry bedding (from 12'45) and COHESIS cooperative for agronomic part (from 21'45)

- Fine straw recovery: a complementary tool for weed flora management, Métais P., Griard E., Perspectives agricoles, no. 431, Press article, 2016

Appendices

Est complémentaire des leviers

- Grow species with varied sowing periods

- Grow diverse species in the rotation

- Clean soil or harvest tools

- Perform false seedbeds during intercrop

- Distribute ploughing in the rotation

Contribue à

S'applique aux cultures suivantes