Spreading digestate

The spreading of digestate is regulated by rules, from the development of the spreading plan to the regulatory obligations of methanization installations:

- Distances and prohibition periods,

- storage and quality requirements,

- nitrogen input limits

Spreading is also linked to environmental issues — volatilization, N₂O emissions, leaching — and ways to limit them, as well as technical and economic issues related to equipment and management of inputs to optimize the agronomic valorization of digestate.

Digestate spreading rules

General principle

As with other organic residual products, spreading digestate in agriculture is possible if it presents an agronomic interest and if its use under recommended conditions does not pose a danger to humans, plants, animals, and the environment.

Spreading plan

A preliminary study, the content of which is defined by the ICPE regime (see Table 2.2), must be carried out to analyze the agronomic value of the materials to be spread and to obtain a soil characterization.

This study results in a spreading plan that identifies the spreading plots, locates them on a map, provides information on the operator and land lenders involved in spreading, and specifies the quantities of nitrogen to be spread per area.

ICPE subject to authorization and registration must also indicate in the annual forecast program the cropping system, the nature and nitrogen contents, the maximum allowable doses per effluent, per soil and per crop, as well as a forecast spreading schedule. A spreading logbook recording the nitrogen fertilization practices carried out for each plot or cultural block must be kept by the operator to trace the operations actually implemented.

For installations subject to authorization, an annual agronomic balance must present a quantitative and qualitative status of the materials spread and summarize the elements contained in the spreading plan. These installations must also comply with safety thresholds according to the decree of February 2, 1998, relating to emissions of any kind from ICPE.

Spreading distance

Table 2.3 specifies the distances imposed for digestate spreading, according to the regime and the category of the methanization installation as well as the spreading rules on sloping land, applicable in May 2021.

| Declaration and registration

2781-1 Registration 2781-2 (without urban sludge) |

Authorization and registration

2781-2 (With urban sludge) |

Authorization

2781-1 |

Authorization

2781-2 (without urban sludge) | |

|---|---|---|---|---|

| Dwelling |

immediate incorporation |

immediate incorporation |

odorous effluent

non-odorous effluent

immediate incorporation |

odorous effluent

non-odorous effluent |

| Drinking water sampling points(1) | 50 m |

slope < 7%

slope > 7% | ||

| Bathing sites | 200 m |

| ||

| Fish and shellfish farming zones | 500 m upstream |

| ||

| Watercourses and water bodies |

10m grassed or wooded strip along watercourse edge

slope > 7% (3) |

slope < 7%, non-fermentable waste and immediately incorporated (2)

slope < 7%, fermentable waste

slope > 7%, solid and stabilized waste

slope > 7%, non-solid or non-stabilized waste | ||

(1) See specific provisions for each drinking water catchment protected by a protection perimeter

(2) Warning, in vulnerable zones, specific recommendations which are stricter must be followed

(3) if slope > 7%: prohibited for liquid digestates under registration, unless devices preventing any risk of runoff and flow towards watercourses are implemented (grassed strip, wooded strip...)

Spreading must be carried out by a device allowing to limit atmospheric ammonia emissions (pendillards, direct incorporation, rapid incorporation after spreading, etc.). In this context, the use of the pallet nozzle is prohibited.

Furthermore, in accordance with the Nitrates Directive, spreading is prohibited:

- on frozen or snow-covered soils

- on flooded or waterlogged soils

- on soils not used for agricultural production

- during periods of heavy rainfall.

Storage devices: capacity and location

The storage structures for digestate must have a capacity sufficient to allow the storage of the quantity of digestate (raw or liquid and solid in case of phase separation) produced over a period corresponding to the longest period during which its spreading is either impossible or prohibited; unless the operator or a service provider has storage capacities on another site and can justify their permanent availability.

Under the ICPE declaration and registration regime, this period cannot be less than four months.

Considering the climatic contexts, spreading calendars in vulnerable zones, crop rotations and spreading practices, it is often recommended to have, at least for liquid digestates, a storage capacity of 6 months.

Digestate storage areas:

- must be at least 35 m away from wells and boreholes for water catchment outside the site, springs, open-flow aqueducts, shores and banks of watercourses, any underground or semi-buried installation used for storing water intended for drinking water supply, food industries, or irrigation of vegetable or hydroponic crops. The 35 m distance from shores and banks of watercourses may however be reduced in case of transport by waterway

- cannot be located within the close protection perimeter of a water catchment intended for human consumption.

It is recommended that the storage site be located at least 50 m away from third parties.

Quality of materials spread

The ministerial decree, which governs the activities of sites under declaration, specifies that the operator must have digestate analyses without specifying their nature or frequency.

For sites under registration (2781-1), at least one analysis per year must be performed at minimum on total nitrogen and mineralizable nitrogen contents.

It is nevertheless recommended that the operator perform at least one analysis of agronomic parameters at each spreading period (dry matter (%), organic matter (%), pH, total nitrogen, ammoniacal nitrogen (as NH4), C/N ratio, total phosphorus (as P2O5), total potassium (as K2O)).

Digestates are subject to safety analyses only if the installations are classified under authorization. The authorization decree then specifies the nature and frequency of analyses to be performed.

It should be recalled that for methanization activities, any use of animal by-products (including endogenous slurry) requires a sanitary approval. Regulation No. 142/2011 sets the requirements concerning the processing standards of treated animal by-products as well as the conditions of use of the resulting digestates.

It also defines microbiological limits for digestates from installations classified under authorization:

- for Escherichia coli and Enterococcaceae:

- out of 5 samples of 1 g each, at least 4 samples must contain a maximum of 1,000 bacteria and one sample may contain between 1,000 and 5,000 bacteria

- in case of non-compliance, a new conversion is requested.

- For Salmonella:

- out of 5 samples of 25 g each, none must present bacteria

- in case of non-compliance, digestates must be handled (composted) or disposed of according to the instructions of the competent authority.

Digestate and nitrogen input limits

For units treating urban sludge and subject to registration or authorization, digestate inputs must not exceed 30 tDM/ha/10 years.

For other units subject to authorization, inputs of pasty or solid digestates must not exceed 30 tDM/ha/10 years.

In accordance with the Nitrates Directive, the quantities of nitrogen spread must not exceed 170 kg of organic nitrogen from livestock effluents per hectare per year.

Respecting the nitrogen fertilization balance at the plot may however lead to limiting the quantities that can be spread to levels below 170 kg N/ha.

Spreading period

In accordance with the Nitrates Directive, Table 2.4 sets the minimum periods during which spreading of type II fertilizers is prohibited. These periods differ according to the land use during or following spreading and apply in vulnerable zones.

These prohibition periods may be reinforced at the regional level.

| Land use during or following spreading

(main crop) |

Minimum prohibition periods for spreading type II fertilizers |

|---|---|

| Uncultivated soils | All year round |

| Crops planted in autumn or late summer (other than rapeseed) | from January 1 to 31(1) |

| Rapeseed planted in autumn | from January 15 to 31(1) |

| Spring-planted crops not preceded by a catch crop, a cover crop or a vegetative cover in intercrop | from July 1 to January 31(2) |

| Spring-planted crops preceded by a catch crop, a cover crop or a vegetative cover in intercrop |

The total inputs before and on the catch crop, cover crop or intercrop vegetative cover are limited to 70 kg of effective nitrogen per ha |

| Grasslands established for more than six months including permanent grasslands, alfalfa | from November 15 to January 15 (3) |

| Other crops (perennial crops, vegetable crops and seed crops) | from December 15 to January 15 |

(1)In some regions, spreading is allowed from January 15

(2) In the presence of a crop, spreading of low-loaded effluents by fertigation is allowed until August 31 within the limit of 50 kg of effective nitrogen/ha. Effective nitrogen is defined as the sum of nitrogen present in the low-loaded effluent in mineral form and in mineralizable organic form between July 1 and August 31.

(3) Spreading of low-loaded effluents is allowed during this period within the limit of 20 kg of effective nitrogen/ha. Effective nitrogen is defined as the sum of nitrogen present in the low-loaded effluent in mineral form and in mineralizable organic form between November 15 and January 15.

Ammoniacal nitrogen volatilization

Ammonia emitted into the atmosphere is a precursor of fine particles recognized for their negative health effects. Digestate is rich in ammoniacal nitrogen (in the form of ammonium). Ammonia (NH3) is emitted from digestate from ammonium (NH4+) in contact with air (NH4+ + HO- → NH3 (gas) + H2O).

The concentration of NH3 in ambient air being much lower than that in digestate, there is a transfer of ammonia from digestate to air, especially when the ammoniacal nitrogen concentration in digestate is high.

This phenomenon is immediate upon spreading and fades quickly with the decrease of NH4+ concentration in digestate. Volatilization is very variable but can reach more than 50% of the ammoniacal nitrogen spread.

It is favored by:

- warm temperatures

- wind

- absence of rain within 24 hours following spreading (rain allows ammonium infiltration into the soil)

- soil pH and/or digestate pH being high.

Incorporation of digestates allows to drastically reduce volatilization, even if superficial; however, it must be done as quickly as possible after spreading because most emissions occur during the first hours after spreading.

For immediate incorporation, ammonia emission reduction is 90%. For incorporation within 4 hours after spreading, it drops to 45-65%. Beyond and within 24 hours it further drops to 30%.

Nitrous oxide emission

Nitrification

Nitrification is the oxidation of ammonium (NH4+) into nitrate (NO3-). It occurs under aerobic conditions within a timeframe ranging from a few days to a few weeks. The process releases gaseous nitrogen in the form of N2O and NO.

Denitrification

Denitrification is the process of transforming nitric nitrogen (NO3-) into gaseous nitrogen N2 under the action of certain bacteria. Under specific conditions (low soil pH values for example), the sequence of chemical reactions is incomplete and leads to the production of intermediate forms of nitrogen oxide including nitrous oxide N2O.

Low in well-drained soils, nitrogen losses by denitrification can be much higher when soil conditions favor this process: anoxia linked to temporary excess water, abundance of nitrogen in nitrate form and presence of labile organic matter.

Direct nitrogen losses as N2O by nitrification and denitrification are generally estimated at 1% of the nitrogen applied on average.

Direct emissions

In addition to so-called "direct" emissions, i.e., emissions resulting from N2O production processes in soils, there are also so-called "indirect" N2O production pathways, which are emissions of N2O from:

- nitrate or nitrite dissolved in waters and carried to groundwater or surface waters by runoff

- deposition of ammonia or NOX which, dissolved in water, transforms into NH4+ and thus feeds again the nitrification and denitrification processes. It can also be transformed into nitrate, leached, and contribute to indirect N2O emissions.

Nitrate leaching

Nitrate leaching contributes to nitric contamination of waters, to eutrophication of aquatic ecosystems and to indirect N2O emissions as described above.

Leaching is the transport of dissolved mineral elements (mainly nitrates NO3-) by water percolation downwards. The amount of nitrates transported beyond the root-accessible zone depends on:

- the drainage water depth

- the amount of nitric nitrogen present (and thus the stock of mineral nitrogen remaining in the soil after crop harvest) and its distribution in the soil profile

- the type and depth of the soil

- the cover of the soil and the ability of the cover to utilize residual nitrogen.

The annual leaching rate varies:

- from 0-5% of nitrogen applied (situation of short intercrops or long intercrops with catch crop, in non-filtering soils such as deep silts)

- up to 30% (long intercrops without catch crop, filtering soils such as sand)

- with intermediate situations at 10 or 20% (for example medium clay-limestone soils, alternating winter and spring crops without catch crop).

For an input of 150 kg nitrogen per ha, between 0 and 45 kg nitrogen can thus be lost by leaching.

For an input of 150 kg nitrogen per ha, between 0 and 45 kg nitrogen can thus be lost by leaching.

Technical and economic issues of nitrogen flow management

Input control, loss limitation

In crop management, the goal is to optimize nitrogen inputs relative to plant needs. For this, it is necessary to consider the yield objectives for the crop, the sources and sinks of nitrogen in the system, and the possible losses in water or air.

For digestate input, determining the amount of nitrogen supplied, actually available to the plant, requires analyses and calculations. Indeed, in digestate, nitrogen is present in mineral form (ammoniacal) and in organic form. The nitrogen in digestate available to the plant is the sum of ammoniacal nitrogen not lost in water or air and the fraction of mineralized organic nitrogen.

This available nitrogen is highly variable depending on digestates (origin substrate and treatment method). That is why an agronomic analysis of digestate must be done before each spreading period.

Moreover, calculating the nitrogen dose supplied by digestate requires using reference Keq coefficients. Regarding nitrogen losses to water and air from digestates, some can be limited by spreading practices: quantities spread, conditions, equipment.

Regarding nitrogen losses to water and air from digestates, some can be limited by spreading practices: quantities spread, conditions, equipment.

Spreading cost

There are various equipment for spreading digestate.

The cost of a spreading operation for raw or liquid digestate with a slurry tanker is very variable. It is diluted by the increase in the volume of activity of the tanker. It increases with distance, and especially the share of the cost related to transport becomes more and more significant with distance.

Spreading without a tanker can also be an interesting option for raw or liquid digestate. The advantage is to reduce the weight of the machines spreading on the field and thus better preserve the soil. The cost of implementation is very variable and often higher than that of a slurry tanker, particularly if it does not rely on pre-existing delivery facilities (for example an irrigation network). In this case, it requires supply by truck or slurry tanker, with a lagoon, a tank or a slurry tanker, to temporarily store the digestate near the plots to be spread. Moreover, the handling of the pump and hose in the field requires a little more handling than spreading by slurry tanker alone.

Soil compaction

The importance of compaction depends on the volume to be spread, the type of equipment (spreading with/without tanker, size of the tractor, tire width), the time of intervention (soil bearing capacity), the nature of the soil and the topography, which allows easier or more difficult passage of the equipment.

Managing digestate inputs

The fertilizing value of a digestate in the year of its application corresponds to the amount of fertilizing elements in the digestate that is absorbed by the crop. It is never the total amount of fertilizing elements in the digestate.

In particular, the availability of nitrogen and sulfur depends on many factors. For potassium and magnesium, in soluble form in digestates, the efficiency is close to that of the reference fertilizer with equivalent fertilizing value, and for phosphorus this efficiency depends on the origin and treatment of the product.

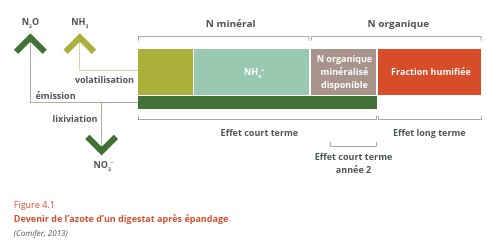

More precisely regarding nitrogen, its mineral part, mainly consisting of ammoniacal nitrogen, is immediately available for crops or lost by volatilization or leaching. The organic nitrogen in the digestate, on the other hand, is released gradually by mineralization (see Figure 4.1). This mineralization is more or less rapid and significant depending on the digestates.

In the calculation of the nitrogen dose to be applied on crops, the contribution of the digestate, taken into account in the parameter Xa, is determined thanks to its composition and a coefficient Keq, such that:

Xa (digestate) = %N (digestate) x Keq x Q (digestate)

With

Xa: amount of effective nitrogen supplied by the digestate

%N: total nitrogen content of the digestate (% per unit volume or mass)

Keq: coefficient of effective mineral fertilizer equivalence

Q: volume or mass of digestate spread per hectare

To know the total nitrogen content of the digestate, it is necessary to perform analyses as close as possible to the spreading date to take into account any transformations during storage.

The Keq is used to estimate the portion of digestate nitrogen available in year n, taking into account the mineral nitrogen present in the digestate at the time of spreading and the organic nitrogen mineralizable within the year, as well as losses (volatilization, leaching).

It is therefore linked to the crop and the time of application (spreading conditions and climate after application).

But the behavior of digestates, and thus the Keq, are linked to their composition, the type of methanized biomass, and interannual climate variations (temperature, rainfall), hence a certain annual variability of the actual nitrogen availability.

In practice, the amount of digestate to be applied is limited, in vulnerable zones, by the ceiling of 170 kg of organic nitrogen of animal origin per ha of UAA per year. It is also limited for applications on catch crops and CIVE. Finally, it may be limited by the needs in other nutritional elements, such as P or K.

Apply at the best time

The equivalence coefficients differ according to the period when the digestate is spread and according to the needs of the crops, linked to their development. They highlight the crops and periods that best valorize the applications of raw digestates. Recommendations are presented in Figure 4.3.

For solid digestate

It is recommended to favor incorporation before crop establishment to allow better valorization of phosphorus. Be careful, as it loses mass during storage. Therefore, if weather conditions and timing are suitable, it is advised to spread regularly and limit storage duration.

For raw or liquid digestate

Storage capacities are crucial. The larger they are, the more freedom the farmer has to spread at the most appropriate time according to crop needs and weather. Therefore, it is recommended to properly size storage for winter (minimum 6 months).

Managing organic matter

Managing fresh organic matter

During the digestion process, microorganisms feed on fresh organic matter and mineralize it. This is why it is strongly reduced in the digestate compared to the raw materials entering the methanization unit. However, the input of fresh organic matter is essential for maintaining or improving soil microbiological activity (biological fertility). Thus, it is recommended to supplement digestate applications with a cover crop. CIVE (Intermediate Energy Cover Crops) that leave a significant root system after harvest partly fulfill this role of fresh organic matter input.

Managing fertilizing and liming power of digestate

Raw digestate can be managed as a complete fertilizer, with both fertilizing power and liming power.

Phase separation however produces a solid fraction and a liquid fraction with very different properties.

The solid fraction concentrates the organic matter as well as phosphorus, and with them the liming power.

The liquid fraction concentrates the ammoniacal nitrogen as well as potassium, and with them the fertilizing power.

Phase separation thus allows different agronomic management according to plot needs, notably a temporal separation of spreading for liming (solid fraction) or fertilization (liquid fraction).

Use appropriate equipment

For better spreading uniformity

Spreading uniformity, characterized by a good transverse distribution (uniformity across the working width) and longitudinal distribution (distribution in the direction of tractor movement) of digestate on the plot, is essential to obtain homogeneous yields on the plot.

For solid digestates, good longitudinal distribution relies on the regular feeding of mills or rotors.

Several equipment options are possible for this, at minimum a moving floor with slats, to which can be added a speed control system, or a guillotine gate. More expensive equipment allows for greater precision: pushing floor, flow proportional to forward speed (DPA) system, continuous weighing equipment.

For raw or liquid digestates, spreading uniformity first requires good homogenization before spreading, to evenly distribute fertilizing elements. Longitudinal distribution of spreading is quite good and more precise than for solid digestates. For optimal longitudinal and transverse distribution, the feeding of the spreading equipment must be regular, notably thanks to a crusher/distributor. Two crushers/distributors are necessary for wide spreading booms (from 15 m).

Operation is further improved with complementary equipment such as flow proportional to forward speed (DPA), satellite guidance, section control, and instantaneous measurement of digestate nitrogen content.

To avoid losses by volatilization

The ammoniacal fraction of raw or liquid digestates is significant, causing substantial risks of nitrogen volatilization. Thus, with spreading by paddle nozzle, 40 to 90% of ammoniacal nitrogen is lost within 6 hours after spreading.

To limit these losses and maximize digestate valorization, the use of paddle nozzles is strongly discouraged. Alternative solutions exist and are presented in Table 5.1 below.

This specific equipment has a significant cost: 35,000 to 50,000 euros for a 12-15 m pendulum boom or a 6 m incorporator with flow modulation system (DPA).

However, when including the fertilizer savings generated by reduced ammoniacal nitrogen losses, spreading costs become similar to those of a paddle nozzle.

Finally, digestate acidification equipment can also be used to limit volatilization. Indeed, in an acidic environment, nitrogen is favored in the form NH4+ and not in its gaseous form (NH3).

One can use an organic acid (lactic acid), inorganic (nitric, sulfuric or phosphoric acid) or add microorganisms that produce acid (lactic bacteria for example).

Acidification can be performed during storage or during spreading:

- the digestate can be pumped to a treatment tank where a dose of acid is added

- the acid can be added directly in the storage facility (where there must be an agitation system) just before the digestate is taken for spreading

- the digestate can be acidified continuously in a system mounted directly on the spreader. In this case, the digestate is spread normally and an additional acid tank is placed in front of the tractor. The device is equipped with a static mixer and an acid dosing system.

Several points of caution should be noted regarding this practice:

- handling of acid is dangerous

- qualitative changes in odors may be generated

- the technique involves additional energy expenses

- the technique may cause marginal soil acidification (to be corrected by liming)

To avoid compaction

Applications using a slurry tanker are often quite detrimental to soils.

It is recommended to:

- choose a tire setup considering the total weight of the tanker

- monitor the total weight of the tanker to avoid overloads

- use a central tire inflation system, which allows adjusting the air pressure inside vehicle tires to improve performance depending on the type of surface encountered.

Spreading without a tanker is a solution that allows less impactful traffic on the plot and lower traction needs (100-120 hp):

- it can be done using a self-propelled machine or a tractor equipped with a pendulum boom

- it preserves soil structure thus allowing digestate valorization on cereals after winter

- it allows a high work rate ranging from 50 to 130 m³/h.

However, it requires a parcel layout close to the pumping point (storage pit, truck, tanker or tank at field edge), a supply network (hoses) and a pump.

For these reasons, it is not well suited to small and scattered parcels and the operation can be made difficult by the presence of obstacles (trees, poles).

Videos

Spreading raw or liquid digestate before corn sowing with incorporation

Spreading raw or liquid digestate on mowing meadow after first cut

Sources

- Sophie Carton and Quentin Bulcke. The use of digestates in agriculture. [03/11/25]. https://projet-methanisation.grdf.fr/cms-assets/2022/06/Utilisation-des-digestats-en-agriculture-web_compressed.pdf

- ADEME, AILE, Solagro, Trame. September 2011. Methanization on the farm - Practical guide

- ADEME. January 2019. Setting up a methanization unit on the farm

- APESA (coordinator), BIOMASSE NORMANDIE, RITTMO. January 2015. Regulatory and legal framework of agricultural methanization and composting activities, Study conducted for ADEME

- Arvalis (coordinator), ADEME, CTIFL, Terres Inovia, IFV, ITAVI, IDELE, IFIP. 2020. GES’TIM+ Guide

- Regional Chamber of Agriculture of Lorraine. May 2019. Technical sheet Methanization digestates: Optimizing soil return to benefit agronomic and economic benefits - Trial results and farm monitoring - 4-year summary

- Chamber of Agriculture of Lorraine. October 2019. Practical guide for project leaders and advisors - Methanization digestates: Optimizing soil return to benefit agronomic and economic benefits

- Comifer. May 2013. Calculation of nitrogen fertilization, Methodological guide for establishing local prescriptions

- CPE Artois Picardie. Methanization units: Digestate spreading, Methodological guide. 2020 edition

- Doublet S., Leclerc B., Couture C. and Berger S. December 2004. Agronomic and sanitary quality of digestates from methanization - Final report

- EREP SA and EAWAG. 24/09/2009. State of the art of (cost-effective) methods for elimination, concentration or transformation of nitrogen for small/medium agricultural biogas plants - Final report

- Regional Federation of CUMA of the West. 2018. Properly spreading digestates from methanization, Technical sheet produced within the TEpLis project

- Gaillot B. and Lavarde P. (coordinator). July 2015. Spreading on agricultural land of fertilizing materials of residual origin - Prospective mission on regulatory framework and monitoring modalities - CGEDD report no. 009801-01, CGAAER no. 14074

- Levasseur P., Soulier A., Lagrange H., Trochard R., Foray S., Charpiot A., Ponchant P. and Blazy V. 2019. Agronomic valorization of pig, cattle, sheep, goat, poultry and rabbit manure effluents. RMT Livestock and Environment, Paris, 83 pages

- Nitrawal asbl, Chamber of Agriculture of Aisne, Chamber of Agriculture of the Nord-Pas de Calais region. Choosing your organic fertilizer spreading equipment. Sheet produced within the SUN (Sustainable Use of Nitrogen) project