Electric weeding

Elimination of weeds by an electric current

Elimination of weeds by an electric current

Electric weeding consists of passing an electric current through the aerial part of the plant, which is conducted down to the roots and eradicates the entire plant (in a closed circuit). It is an alternative to chemical, mechanical, and thermal weeding, notably for the safety of users and soil life.

Operation

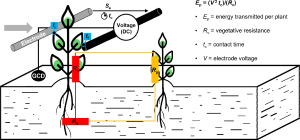

The electricity comes from converting the tractor's power into a high-voltage current. Electrocution is performed using a series of applicator plates that drag over the vegetation one after another. The positive charge carried by the first rows of electrodes generates an electric current that passes through the plant. The second row of electrodes, with opposite charge, returns the current to close the circuit. The electric current transforms into thermal current which vaporizes internal liquids and causes the bursting of vascular tissues, killing the plant or preventing its growth. The electric current passes through the entire plant, leaves, stems, down to the roots.

Conditions

- Weed density: Equipment performance may be reduced if density is too high.

- Plant moisture content: Plants with higher internal moisture content can better conduct the current, resulting in better control.

- Soil moisture: Higher soil moisture can provide better soil conductivity which dissipates the current in the plant and reduces its effects.

- Slope: Uneven terrain can cause weeds to be missed by electric treatment when using a fixed-height electrode set.

- Gap between crop and weeds: If there is insufficient height difference between the weed and the crop, the risk of accidental contact causing crop injury is increased.

- Biomass, aerial plant density: Continuous conductivity with aerial parts limits root action as the effect may be more superficial. If biomass is too high and may reduce weeding efficiency, it may be advisable to mow the cover before electric weeding.

- Speed: Working speed determines the amount of energy applied and the contact time of electrodes with weeds. Effectiveness is higher at 2 km/h than at 3 km/h. Increasing application speed reduces electrode contact time and thus the energy applied. Studies have shown that for each doubling of voltage, electrode contact time can decrease by at least 4 times with the same result.

Advantages

- Does not use chemical products: No legal restrictions.

- Leaves no toxic residues in the soil: No impact on soil life.

- Systemic effect (current travels through the plant, from leaves to roots): Higher durability of weeding.

- Closed circuit: Limits drift into the soil, if moisture conditions are met.

- No soil movement: Erosion minimized and preserves soil structure.

Disadvantages

- Soil moisture: Effectiveness is improved in dry conditions but if too dry there is a risk of fire start. Too wet soil is penalizing, current can dissipate into the soil and not remain concentrated in the plant.

- It is not selective: Care must be taken not to cause injury to crops.

- Grasses are harder to destroy because their leaves have less contact surface.

- The larger and more lignified the plants, the harder it is to achieve complete electric arc action, which flows better when plant conductivity is high. Higher cellulose and lignin content in cell walls can increase cell resistance to bursting.

- Multi-branched weeds may have reduced mortality due to energy dissipation.

- Working time: Reduced speed limits worksite speed.

Compared to other systems

Thermal weeding

Electric weeding should not be confused with thermal weeding which consists of creating a thermal shock using air heated to 650°C by a resistance subjected to electric current. Although the principle is the same in drying weed cells and causing their bursting, for purely electric weeding, a second electrode is placed at soil level to recover the current and thus close the electric circuit.

Mechanical weeding

Unlike manual or mechanized hoeing, electric weeding does not cause soil movement. Thus, it avoids erosion, disturbance of soil structure, and induction of seed dormancy. As killed plants remain in place, the soil surface remains shaded and new seeds will not find a favorable seedbed for germination. Thus, weed regrowth is delayed.

Economic consequences

In arable crops, the cost of use ranges between €110 and €250/ha, including labor, from 200 ha deployed per year. This cost is linked to the low forward speed which lengthens operation duration. The technique is therefore much more expensive than management by glyphosate or soil tillage (these figures come from trials conducted by Arvalis in 2018 and 2019) but these results may evolve according to progress by various manufacturers.

Compared to manual weeding, in market gardening or viticulture, the cost is greatly reduced, between 20 and 28 times lower.

Environmental consequences

- Impact on soil life: Electric current can potentially affect cellular components, structure, and viability of soil organisms, especially those directly attached to shoots and roots of the treated plant: earthworms, pests... However, compared to other methods (chemical and mechanical), it is comparable or more stable. Further research is needed for more details.

- Impact on seeds: Electric current can also reduce pollen production and seed viability.

For more information

- Review, Western Australian Agricultural Authority and Zasso Group AG, 2023, Exploring the potential of electric weed control

- Trial results, Arvalis, 2022, Alternatives to glyphosate - Electric weeding, a promising no-till approach

- Technical sheet, GECO écophytopic, 2019, Practicing electric weeding

- Technical sheet, GECO écophytopic, 2022, Electric weeding in vineyards

- AgroNotizie, 2023, XPower XPR: the electric solution for row crop weeding

- Herbicide-free agriculture - Joseph Pousset France Agricole, Book, 2003 Joseph Pousset is an organic farmer from Normandy (Department of Orne).

- Article, Michigan State University Extension, 2023, Electrical weed control in vegetables and field crops

Appendices

Contribue à

S'applique aux cultures suivantes