Utilisation des macérations de plantes en grandes cultures :what role, what results

The macerations, fermented extracts or manures or Natural Substances for Biostimulant Use (SNUB), are natural preparations based on plants. They allow to boost growth, unlock yields, stimulate the natural defenses of plants... the effects of macerations are multiple.

Principle

The principle of a maceration is to extract the active substances (secondary metabolites) contained in a plant to spray them on the crop or on the soil. Under the action of the microorganisms they naturally contain, the plant species used (nettle, comfrey, kelp, alfalfa, horsetail, burdock) undergo fermentation. The result is the production of molecules of interest for the soil and the crops: it contains trace elements in chelated form, minerals, amino acids, enzymes, antioxidants and microorganisms that will promote the assimilation of these elements.

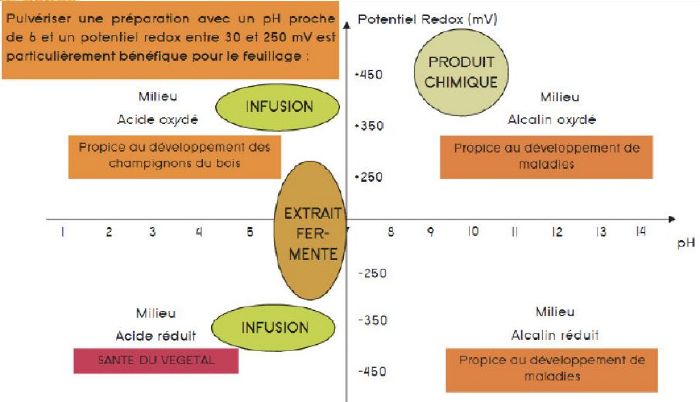

The Redox Cross

The notion of Redox is important to understand for the correct use of macerations. The principle of fermented extracts is to reposition the plant sap at a correct Redox level in order to limit the development of diseases.

- The pH is an indicator of the acidity level, of the concentration of H+ ions in the medium.

- The Redox is an indicator of the redox state of the sap of a plant, of the concentration of electrons (e-) in the medium:

- The more oxidized the plant is, the less concentrated it is in electrons, the lower its energy level and the less efficient the photosynthesis.

- The more reduced the plant is, the more concentrated it is in electrons, the higher its energy level and the more efficient the photosynthesis.

- Synthetic products such as fungicides have a curative action (neutralization of the pest and limitation of disease spread) but also oxidize the medium and cause stress to the plant.

Oxidized media with alkaline pH favored the development of fungi such as downy mildew or septoria.

Benefits

Macerations mainly act on two points:

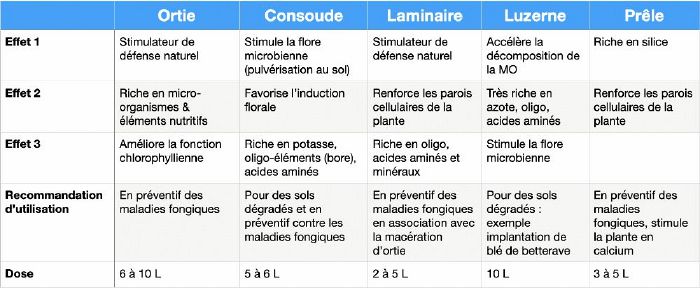

- Crop protection: some macerations, such as those of nettle and kelp, stimulate the natural defenses of plants. They also allow to reposition the sap of the plant at a correct redox level, making the environment less favorable to the development of fungal diseases.

- Stimulation of soil life: macerations of comfrey and alfalfa stimulate the soil microbial flora and accelerate the decomposition of organic matter.

Protocol

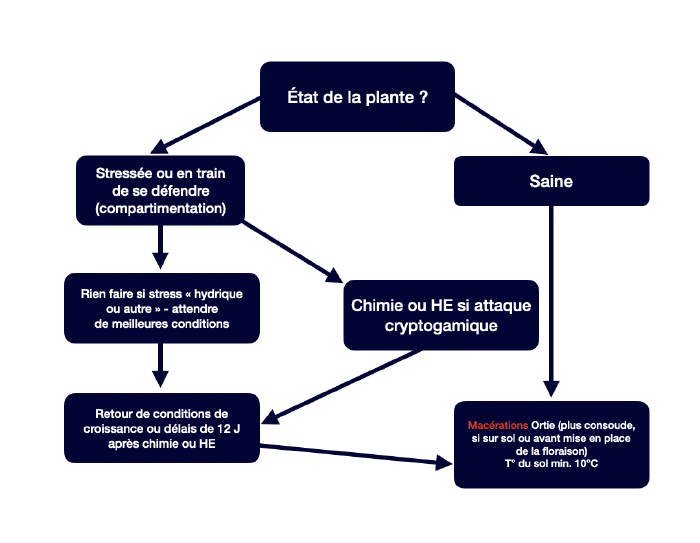

- First question: plant condition (stressed or healthy). If the plant is stressed or defending itself, wait for better conditions. Use chemistry or essential oils to intervene. Only 10 to 12 days later can you return with the maceration.

- Use sap analyses to adjust the necessary elements.

- Soil temperature: minimum 10°C.

- Proportion: a maceration is at least 10% of the spray mixture, which can be broken down into 2 times 5%.

Manufacturing process

Making it at home allows optimizing production costs compared to fermented extracts bought commercially. Here are two types of artisanal manufacturing:

- Anaerobic manufacturing: This type of manufacturing allows better control of the process (because the preparation is not in contact with air oxygen), but it is more tedious to carry out because it requires more monitoring.

- Open-air manufacturing: It is in contact with air oxygen but without an aeration system (as for aerated compost tea preparation). Easier to carry out but with less control.

Steps to follow

Step 1: harvesting

- In the morning;

- Just before flowering:

- Harvesting too early risks the plant not being rich enough in nutrients.

- Harvesting too late risks the plant having migrated its nutrients to its reproductive organs.

- Put into maceration no later than 3 hours after harvesting.

Step 2: putting into tank after harvesting

- The tank filling must be done no later than 3 hours after harvesting.

- The method differs depending on the type of manufacturing chosen.

Step 3: monitoring fermentation

Monitoring is essential to ensure the quality of the final product and identify the right moment to stop fermentation and start filtration. This monitoring can be done through indicators measured with specific devices: pH, Redox and conductivity. The cost of measuring devices can be a barrier to purchase (around €500), so there are also methods to monitor without devices.

Using measuring devices

- The first indicator to look at is the redox: it should be between -100 mV and +100 mV.

- The second indicator is the pH: it should be between 4.8 and 6.

Measuring without devices

There are visual methods to identify if fermentation is finished.

Foam test:

- Left: thick foam on the surface that remains on fingers when touched → fermentation in progress.

- Right: fine foam that dilutes → fermentation finished.

Color test:

- Left: light yellow-green color indicates that the maceration is correct.

- Right: brown color indicates that fermentation lasted too long and the product is of poor quality.

⚠️ If the product is light yellow at bottling and dark brown at use time, it means the bottle was not airtight and fermentation resumed during storage.

Step 4: bottling

A final step not to be neglected, bottling and storage must be done under good conditions to ensure a quality product at use.

- Macerations made in May-June at an ambient temperature of about 20°C take on average about ten days.

- There must be no air in the bottle to avoid restarting fermentation: the simplest technique is to let the bottle overflow.

- It must be stored in a dark room at a temperature between 7°C and 17°C and without thermal amplitude.

- To ensure good preservation for one year, it is recommended to add 0.2 g of acerola per liter of maceration (or 50 mg of vitamin C).

Anaerobic manufacturing

Necessary equipment

- Rainwater (pH 6-7; Redox below 200 mV; Conductivity below 0.3 mS/cm);

- A stainless steel or plastic tank;

- A rigid plate (plywood, plastic circle) + inner tube of the tank diameter for sealing (remember to pierce the plate to allow air evacuation);

- A tarpaulin to surround the rigid plate (also for sealing);

- A tap.

Filling the tank after harvesting

- Fill the tank 3/4 full with rainwater (water can be heated to 30°C to speed up fermentation);

- Put fresh plants in the water: 1 kg/10 L (only one species per tank);

- Place the tarpaulin on the water and plants to create anaerobic conditions (the tarpaulin must extend beyond the tank);

- Place the rigid plate on the tarpaulin;

- Place the inner tube of the tank diameter on the plate and inflate it to put the medium in anaerobic conditions;

- Place a weight on the plate to prevent it from rising;

- Pierce the tarpaulin to allow air evacuation;

- Close the lid.

Open-air manufacturing

Necessary equipment

1000-liter IBC (cut off the top part and keep it) or a stainless steel tank.

Filling the tank after harvesting

- Fill the tanks with freshly cut plants 1 kg/10 L (in a 1000 L tank: put a maximum of 80 kg of plants for 800 L of water).

- Heating the water speeds up fermentation (not mandatory).

- Place the lid with weights on the plants and water.

- Maceration must be done in a building without thermal amplitude and strong light.

Characteristics of main plant species used in maceration

Points of caution

- Application pressure: Too high a pressure will negatively impact microorganisms. Use a spraying pressure of 1.8 to 2 bars, no higher. Also, the nozzle tends to oxidize the maceration: the lower the pressure, the less the preparation is micronized, the less it is oxidized.

- Sprayer rinsing is very important. A complete cleaning is required before applying the maceration. Ideally, leave it in full sun for an afternoon as UV breaks down synthetic molecules.

- Overstimulating the plant can weaken it. “The goal is not to ask the plant to produce more, but to help it reach its production potential. Often, the best results are where there is little visual difference with the control. You have to go up to the yield. Sometimes visual results can be misleading. It’s the ‘green effect’ due to excess nitrogen or iron, plants are green and exuberant. In the end, this can penalize tillering or grain filling in cereals. It’s flattering but can sometimes be counterproductive.”

Economic data

Cost of manufacturing process

Commercially

- Prices of macerations vary on average between €1 to €3 per liter.

- For a nettle maceration used at 10 L/ha: the cost price is about €10 to €30/ha.

Artisanal manufacturing

Home manufacturing takes into account the labor cost to make it and equipment depreciation:

- Mowing and filling tank for 2500 L: 2 h.

- Monitoring: 1 h spread over 10 days.

- Bottling: 3 h.

In total, to make 2500 L of nettle maceration:

- It takes about 6 hours of labor.

- With an hourly rate of €80/h (labor and machinery included), this represents €480 to produce 2500 L.

- Home manufacturing allows obtaining a product at €0.20/L.

Cost of using macerations

Conventional fungicide program

- T1 = €25/ha

- T2 = €40/ha

- T3 = €20/ha

- Total cost of the program: €85/ha

Feedback from program using macerations

- T1 = €0/ha of chemicals (replaced by 3 passes of nettle + comfrey at €10/ha)

- T2 = €20/ha of chemicals

- T3 = €15/ha of chemicals

- Total cost of the program: €45/ha

Trial results of maceration use

These trials aim to show the concrete effects of plant macerations in a cereal cropping system compared to synthetic fungicide products.

Trial #1

This first trial was conducted at Antoine Chedru, member of AgroLeague in Seine-Maritime (76), within the Dephy farms, Ecophyto program from 2016-2020.

The objective was to compare the impact on yield of soft wheat of integrating different fermented extracts, with or without fungicide application.

Context

- Area: Seine-Maritime (76) - high disease pressure context.

- Soil texture: deep loam.

- Crop: varietal mixture of 10 different soft wheat varieties in no-till.

- The trial was conducted on strips of 19x100 m, with yield sensor analysis of the combine harvester (trial not conducted in micro-plots so no statistical analysis).

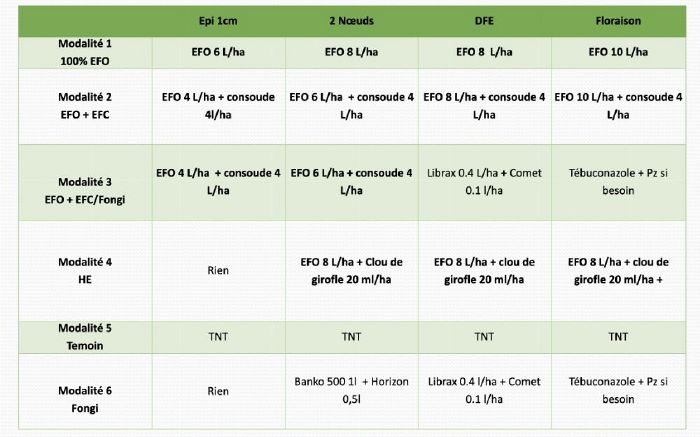

Tested modalities

- “EFO” = “fermented extract of nettle”

- “EFC” = “fermented extract of comfrey”

- “HE” = “essential oils”

Results

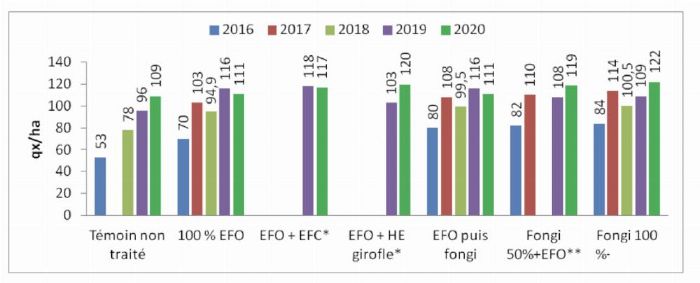

After 5 years of trials, here is the comparison of the different modalities in terms of yield:

- There is a yield gain for the 100% EFO modality compared to the untreated control. For the year 2016, when particularly high disease pressure was observed, the untreated control yielded 53 q/ha versus 70 q/ha for the 100% EFO modality, i.e. 17 q/ha more.

- That same year, the EFO + fungicide modality achieved a gain of +10 q/ha compared to the 100% EFO modality.

- Finally, the 100% fungicide modality only allowed a 4 q/ha gain compared to the EF + fungicide modality.

Margin comparison

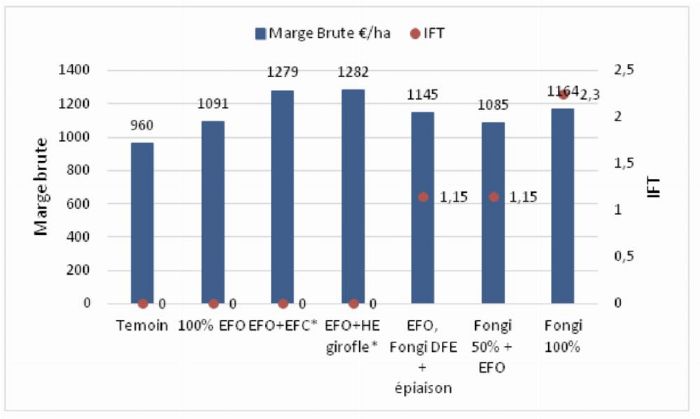

An average price of €180/t was used in this exercise for wheat:

- The 100% nettle macerations allowed a gain of +€131/ha gross margin compared to untreated controls.

- Between the EFO + fungicide DFE modality and the 100% fungicide modality, the difference in gross margin is only €20/ha in favor of the first. However, the treatment frequency index (IFT) dropped from 2.3 to 1.15. This aspect may be interesting to consider in a context of High Environmental Value (HVE) certification for example.

Trial #2

This second trial was conducted at Christophe Vandewalle in Damville in Eure (27) by Ver de Terre Production in 2021.

Similarly to the previous trial, the objective was to compare the impact on soft wheat yield of fungicides, fermented extracts, EF + fungicide and aerated compost teas.

Context

- Area: Eure (27).

- Crop: soft wheat.

- The trial was not conducted in micro-plots so no statistical analysis.

Results

In this context, nettle macerations did not provide a yield gain compared to the untreated control.

Plausible explanations:

- Septoria was present on the F2 at the time of passes with nettle macerations around the last unfolded leaf. In this hypothesis, it would demonstrate the amplifying effect of the disease and thus the negative effect on yield of maceration applications on declared diseases.

- The maceration used was of poor quality.

Video

Conclusion

Key points on the method

- Harvest just before flowering and put into tank within 3 hours. About ten days of fermentation with water at 30°C, anaerobic or not.

- Control the finished product: pH = 4.8 to 6; product clear and foam-free.

- Each species has a different role.

- Interesting if cost is lower than a fungicide.

Key points on their use

- Macerations stimulate growth by providing trace elements and microorganisms.

- They help the plant regain homeostasis after a stressful event (climatic or human origin).

- Effective in preventive, do not apply on declared fungus: applications on diseased or stressed plants are rather weakening.

- Do not mix a maceration with a synthetic product (effects of both are reduced).

- Macerations store very well under good conditions, unlike aerated compost teas.

We have seen that macerations are very effective tools that can stimulate defenses or restart plant growth. Stéphane recommends however to start using macerations on trials. “Do not add too many elements at once, otherwise you risk being lost in the effects. Go slowly and sustainably, do trials, observe and improve.”

Sources

- Maceration manufacturing process, AgroLeague

- Plant maceration - Economic data, AgroLeague

- Integrating macerations into an ITK in arable farming, AgroLeague

- Plant macerations: an economical alternative for crop protection, AgroLeague

- Plant macerations in arable farming: what role, what results? - the feedback from Stéphane Billotte, Article, AgroLeagueLa version initiale de cet article a été rédigée par Stéphane Billotte.