Success Conditions for Implementing a Corridor Silo

Silage is the method of forage storage that allows the best preservation of energy value for up to one year. However, the silo that will enable this storage must be properly constructed. What are the keys to a good setup of a bunker silo?

Before harvest

First, it is necessary to repair and seal cracks in the walls, remove debris (feed, plastic, weighting materials), mow adjacent areas, and develop a plan for harvest, transport, wrapping, and plan equipment and labor. Several key steps follow.

Choice of the silage tarp[1]

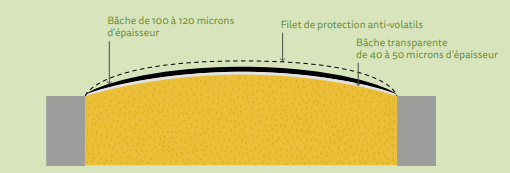

It is essential to choose a high-quality tarp that allows no exchange between outside air and inside air and has UV resistance. The tarp must also be resistant to punctures and tears. The size is defined according to the silo dimensions. For bunker silos, 30% extra width should be planned.

What elements should be considered?

- Color : The silo tarp functions as a barrier to oxygen and light, which is why it is dark-colored : usually black or bi-colored black-green for example.

- Light tightness : A silo tarp of 100 to 150µ is the best solution for excellent light tightness.

- Air tightness : Overlaying a silo tarp on a thin 40µ film, very flexible and that will conform to the silage surface and adhere from the first fermentations, ensures excellent airtightness quickly.

- It may also be useful to add a protective net against bird damage.

Silo dimensions

Several factors must be considered when choosing silo dimensions. First, know the current and future needs of the herd in forage. Then recall the target feed-out rate.

The minimum width of the bunker silo must be calculated based on the distance between the outside of the tractor wheels so that the middle of the silo can be compacted.

The goal is to plan a maximum surface area to allow layers of 15cm height. Then, always respect a respectable height relative to the walls, up to 50cm above the walls.

Tips :

- The silo width must be a multiple of the width of its feed-out tool to ensure homogeneous daily feed-out with optimal forward speed.

- The silo wall height must not exceed the maximum height reachable by its feed-out tool.

- A forward speed of 10cm/day is recommended as long as the outside temperature does not exceed 15°C and 20 cm beyond that.

Example

Step 1 : Calculate the daily need of your animals.

For a farm with 80 dairy cows fed with 6kgDM of corn ear per day. Convert to fresh matter. One kg of corn dry matter equals 55% fresh matter (FM).

6 kg DM / 0.55 = 11 kg FM.

Total daily need = 11 x 80 = 880 kgFM.

Step 2 : Estimate the volume representing this daily need.

Total daily volume (m3FM/day) = Total daily need (kgFM/day) / Density of corn ear silage (on average 775 kgFM/m3 FM).

Total daily volume = 880 kgFM/day / 775 kg/m3 FM = 1.14 m3 FM/day.

Step 3 : Silo sizing.

- Calculate height if wall width is fixed :

Height (m) = Total daily volume of corn ear (m3 FM/day) / (Width (m) x Forward speed (m/day)).

- Calculate silo width if wall height is fixed :

Width (m) = Total daily volume of corn ear (m3 FM/day) / (Height (m) x Forward speed (m/day)).

- Calculate silo length when wall height and silo width are fixed :

Length (m) = Total daily volume of corn ear (m3 FM/day) x number of feeding days / (Width (m) x Height (m)).

Reminder : The specifications for PGI allow distribution of corn ear silage only from October 1 to May 1, a maximum of 210 days.

Farm with a total daily need of 1.14 m³ FM/day of corn ear, distribution over 210 days, and an average forward speed of 15 cm/day. The farm has a silage bucket 2.4 m wide and wants to feed out using 2 bucket widths. The silo width must therefore be at least 4.8 m. Thus, the wall height and silo length will be :

Wall height = 1.14 / (4.8 * 0.15) = 1.6 m.

Silo length = 1.14 * 210 / (4.8 * 1.6) = 31.2 m.

Preservatives

Preservatives[2] help prevent silage mold. They must be planned before the installation period of the silo. There are three main families of preservatives :

- lactic acid bacteria (with or without enzymes),

- organic acids,

- tannins.

Note that the use of preservatives is done without chlorinated water because chlorine would kill all present bacteria.

To choose the right preservative, first select one specific to the forage type. The preservative formulation must address the crop's issues. For example, corn is prone to aerobic instability because it has a high sugar and DM content. One can use a strain of Lactobacillus buchneri which improves aerobic stability. Conversely, grass silages have lower sugar and DM contents that do not ensure optimal acidification. It is better then to use a homofermentative lactic acid bacteria strain that produces acid lactic acid.

If corn is too dry, these bacteria are also used.

Preservatives are applied uniformly during harvest.

Harvest and silo setup

Harvest

Grass

A cutting height of 8-10 cm and a cutting length of 3.5-4 cm should be planned.

Corn

Whole plant corn silage

A cutting height of at least 20 cm for whole plant corn is preferred. The objective is to harvest grain with a dry matter content between 50 to 60% DM (36 to 40% grain moisture) and an average DM of 32 to 35% for the whole plant.

Too early harvest limits yield and starch content, which can cause juice losses and reduced silage digestibility.

It is advisable to adjust the cutting length from 13 to 19 mm depending on :

- overall DM content,

- type of feed-out tool (forage harvester, bucket, silage unloader),

- distribution method,

- amounts of concentrates and other forages associated at the feed bunk for sufficient ration fiber (see Pen State sieve standards).

If a Schredlage-type cracker is used, aim for an average length of 22-26 mm or more.

Corn ear

For corn ear, aim for maximum grain cracking with an average DM of 55 to 65% (grain vitreous stage).

Filling and compacting the silo[3]

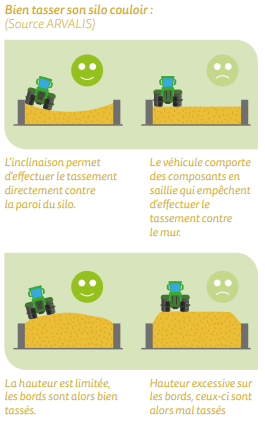

Plan a maximum surface to obtain layers of 10 to 15cm. This will allow better compaction. It is imperative to compact the layer well before adding the next one.

At the start of the work, it is advised to form a basin with the forage as this allows compaction against the walls. If the silage height has been limited to 50cm above the walls, the edges will be well compacted.

At the end of the work, it is better to compact the upper layers longer as they do not benefit from the weight of forage above.

Anaerobic conditions

The silo must be in strict anaerobic conditions. It is necessary to check that no air enters after hermetically closing the silo using tubes (or tires) placed either along the entire length or in rows every three meters so that the tarp perfectly fits the silo. These anaerobic conditions must be maintained for at least 4 weeks where the pH will then be below 4.

It is very useful to add tarps on the walls as this prevents air and water from passing through cracks and extends their lifespan.

Risks if good practices are not followed

In the presence of oxygen and a suitable substrate, molds[3] can develop. This can be due to stressed harvest, slow silo filling, too long chopping, poor compaction, and insufficient feed-out front advance.

If bands are observed across the entire width of the feed-out face, molds are due to a work stoppage during silo setup causing a dehydration zone. If they develop in pockets across the entire height of the feed-out face, it indicates insufficient compaction.

| Molds with toxicity risks | Molds without toxicity risks | ||

|---|---|---|---|

| Fusarium | White then pink, cottony appearance and present in the mass. Can cause diarrhea and intestinal hemorrhages. Must be sorted out! | Monascus | White then red, localized on the periphery or even in the mass in case of very dry and poorly compacted corn. |

| Aspergillus | Dark green with diffuse appearance, develops on a feed-out face advancing too slowly. Does not affect the palatability of corn ear silage. | ||

| Byssochlamys | White with compact appearance. Decreases palatability and presents risks of bloating and rumen blockage. | Penicillium | Blue to light green, present on the feed-out face at the start of silo opening. Does not affect the palatability of corn ear silage. |

| Mucorales | White then gray spotted with black dots, develops on the feed-out face at the start of silo opening with too dry harvested corn. Does not affect the palatability of corn ear silage. | ||

For further reading

Also see the page on how to improve your bunker silo through audits.

- ↑ https://www.vital-concept-agriculture.com/blog/ensilage

- ↑ Large herds, Choosing your silage preservative well : https://www.grands-troupeaux-mag.fr/3-conseils-pour-bien-choisir-son-conservateur-densilage/

- ↑ 3.0 3.1 Guide to good practices for making and distributing corn ear or wet grain corn silage : https://www.emmental-de-savoie.com/wp-content/uploads/2020/08/Guide_Ensilage_Mais_2020_Web.pdf