Reducing Heat Stress in Cattle

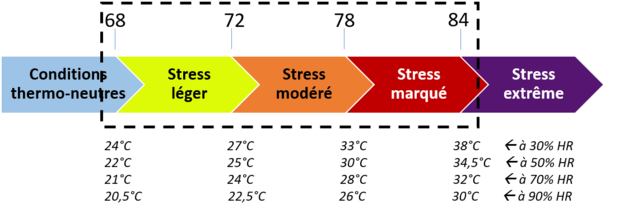

When the THI index, which combines temperature and humidity, exceeds 68, i.e. 22°C and 50% humidity, animals are uncomfortable : they stamp, pant, eat less. By creating a stressful situation, heat has harmful consequences on the physiological needs and welfare conditions of livestock animals, both short and long term[1]. Here is an overview of good practices to implement to limit heat stress in cattle.

Heat stress in cattle

Stress conditions

Heat stress is measured by the Temperature Humidity Index. It takes into account the ambient temperature and relative humidity. It is considered that beyond a value of 68, corresponding for example to a temperature of 22°C with a relative humidity of 50%, a dairy cow already suffers from mild stress impacting its production[2].

A cow’s sensitivity to heat stress depends on many factors[3] :

- the breed,

- the stage of lactation,

- the level of production,

- the feed intake and ration composition,

- the housing,

- the body condition,

- the behavior.

For example[3] :

- Prim-Holstein cows, high producers (> 9,000 liters) early in lactation and with parity 1, 2, and 3 are the most sensitive : their own heat production is twice as intense as that of lower producing or dry cows.

- Heifers generate less heat due to a lower metabolism and a higher size/weight ratio.

Impacts of heat waves on the herd

Heat waves cause physiological changes in animals[4]...

- Reduction in feed intake and rumination at a rate of 0.85 kg dry matter per degree beyond a critical THI value of 72[3].

- Decrease in ruminal pH, risk of acidosis, salivary losses.

- Increase in respiratory rate : from 20 breaths per minute under normal conditions, it rises above 100 during heat stress. Once temperatures exceed 25 °C, this rate can rise to 50 per minute, causing a decrease in bicarbonate levels.

- Increase in body temperature.

- Increase in standing time : this allows the animal to increase heat exchange capacity between its body and the environment (losses by radiation).

- Increase in peripheral blood circulation for thermoregulation purposes. [3]

- Sweating : loss of sodium, potassium and bicarbonate.

- Reduction in activity.

- Disruptions in hormonal secretions.

- When THI is above 84 for several hours, without dropping below 74 during the night, mortality may be observed[3].

.... and impact animal performance[4] :

- Decrease in reproductive performance : an increase in THI can have repercussions for 3 to 5 weeks, leading to an increase in non-pregnancy rates[3].

- Decrease in milk production up to 600 to 900 kg of milk per cow[3].

- Impact on milk composition : decrease in contents, modification of fatty acid profile.

- Impact on pregnant cows and newborns : decrease in calf birth weight, abortions, decrease in IgG content of colostrum as well as reduced calf vitality. Furthermore, housing calves in hutches contributes to worsening heat stress for this category of animals.

- Metabolic problems.

- Fatigue, lameness.

- Impact on udder health : cells, mastitis.

Limiting the impact of heat waves

Water supply

- The water requirement can double during heat waves[3].

- Check if the number of drinkers, their capacity and accessibility are adequate and if cows actually have access to water ad libitum. Water availability at drinkers is often a limiting factor in farms while water consumption in hot weather allows thermoregulation of cows.

- The water reserve and/or flow rate are insufficient when suction noises are heard.

- If cows wait before drinking, it means the number, length or space around drinkers is insufficient.

- Increase the total width of drinkers up to 9 m for 100 cows and provide cool water (10 °C for example), clean drinkers every 2 days.

- Control the water quality of drinkers (chlorine, sulfates).

Recommendations for sufficient water access

- Drinker length per cow : minimum 6 cm, optimum 10 cm in summer.

- Maximum distance between two drinkers : 20 m.

- Water flow rate : 15 to 20L/min.

- Minimum water height in drinker : > 7 cm.

- Drinker height : 0.70 to 0.75 m.

- Lateral space : ≥ 3.60 m[5].

Feeding

With a risk of reduced feed intake, accompanied by lower ruminal activity and decreased salivation, animals can develop ruminal acidosis. To prevent this, various levers can be implemented :

- Increase feeding frequency during the day and provide a large meal in the evening, after milking : increase from one-two times to four-six times per day, to limit the rise in core temperature following feed intake, especially for high producers[3].

- Reduce the effects of peripartum energy deficit by maintaining intake in dry cows (4 weeks prepartum)[3].

- Adjust ration composition[3] :

- Moisten the ration : adding 1 to 2 liters of water per cow to the total mixed ration compensates for daily losses[4].

- Regularly monitor mineral balance (K, Na, Cl, P) : if necessary, increase K, Na and Mg levels in the ration.

- Beware of the cation-anion balance (Baca in lactation), which should reach 300 to 400 mEq (milliequivalents) per kilogram of dry matter.

- Beware of silo feed-out rate which must be sufficient to avoid heating and maintain cleanliness of troughs.

- Yeast supplementation is interesting in combating acidosis, especially during this period.

Animal shading

- Create and facilitate access to natural shade.

- Reduce movement between the milking parlor and the pasture.

- Reduce time spent outside during the hottest hours (11 a.m. - 5 p.m.).

- Shade is provided by trees and their foliage in pastures. Trees not only block solar rays, evaporation of moisture from leaf surfaces also cools the ambient air. Improving the sensation of coolness, tree shade is therefore very appreciated by animals.

- Temperature in the shade of trees, edges, undergrowth can reduce ambient temperature by 3 to 5°C.

- In the absence of shade in grassland, favor night outings.

Bring animals indoors

If tree shade is insufficient or nonexistent, the building must provide a comfort zone for the herd :

- Reduce the number of cows to avoid overcrowding in the building.

- Reduce the number of cows per group in the waiting area to small groups, even if milking is brief (rotary) to avoid crowding in this zone.

- Observe cows’ preference for certain cubicles or areas, which may indicate direct solar radiation in other zones (especially afternoon).

- Shade the feeding area (4 to 5 m² of covered area per cow).

- Animals must be protected from direct or indirect solar radiation by limiting or removing (for roof skylights exposed to sun) translucent roofing, making skylights opaque with paint, installing roof overhangs, shade nets, and reducing the height of concrete walls near animals.

Improve natural ventilation

Wind is a valuable ally to renew air and reduce the perceived temperature by animals.

- The building should resemble a parasol with large openings at the lower part on the long sides allowing cross ventilation.

- Depending on orientation, claddings can be temporarily removed or replaced by adjustable openings (shutters, etc.).

- Regarding artificial shade, not all materials are equal. Thus, white aluminum, nylon with double neoprene layer, white galvanized metal, unpainted wood and forage bales are the best insulators.

- A roof slope greater than 33% hinders evacuation of hot air through the upper part of the building.

- To optimize ventilation, side walls should be at least 4.30 m high.

- The best barn orientation is southwest. Indeed, a north-south or east-west orientation increases direct radiation on it, especially in the afternoon.

- On a north-south oriented building, installing curtains on the west side will limit heat entry between 1 p.m. and 8 p.m. Outside this period, curtains are raised to allow air exchange and ventilation.

For more information on optimizing natural ventilation in a livestock building, see this article.

Install mechanical ventilation

Mechanical ventilation has two objectives :

- Help renew ambient air in all seasons[5] : a volume of air is moved and will favor fresh air entry by slight depression, provided the building is sufficiently open. Mechanical ventilation supplements natural ventilation deficits due to insufficiently wind-exposed buildings or excessive width or to dry bedding areas.

- Provide high air speeds at animal level to promote heat dissipation[5] : if building improvements and farming practices are insufficient, mechanical ventilation can be an option to increase air speeds and thus reduce perceived temperature by animals. By creating high-speed air circulation (about 1 to 3 m/sec), water evaporates from the skin surface and animals perceive a cooling sensation. This is the goal during heat waves. In hot periods, the objective of mechanical ventilation is to achieve speeds over 1 m/s at animal level. Fans equipped with speed controllers should accelerate between 16°C and 21°C to reach maximum speed between 27°C and 29°C.

Criteria for choosing a mechanical ventilation solution depend on :

- building configurations.

- objectives sought.

Several solutions are currently offered on the market[5] :

Old generation horizontal flow fans

- Action length of 9 to 12 m

- Action width of 2 m to 2.5 m

- Disadvantages :

- Reduced efficiency.

- High noise and electricity consumption.

- Very large number of fans to install.

New generation horizontal flow fans

- Action length of 9 to 15 m

- Action width of 5 m to 7 m

- Advantages :

- High air speeds at the animal’s flank.

- Greatly improved performance compared to older generation equipment, with reduced electricity consumption and noise level.

- Disadvantages :

- Higher noise level compared to blade fans.

Directed flow fan

- Action length of 12 to 14 m

- Action width of 4 to 5 m

- Advantages :

- Can be installed quite low in low-height buildings or above rows of cubicles.

- Disadvantages :

- Narrower “working” width and lower air speeds compared to new generation fans.

Blade fans with inclined flow

- Action length of 12 to 14 m.

- Action width of 5 to 6 m.

- Advantages :

- Air speeds directed towards animals.

- Limited noise.

- Disadvantages :

- Sufficient height required.

Large blade vertical flow fans

- Action diameter of 10 to 12 m depending on fan sizing (generally double that of the fan).

- Advantages :

- Air renewal within the building.

- Ventilation (drying) of resting areas.

- Limited noise.

- Disadvantages :

- Limited air speeds.

- Not adaptable in all buildings (depending on available height and roof structure clearance).

Vertical flow fan with deflector

- Action diameter of 8 to 10 m.

- Advantages :

- Air renewal within the building.

- Ventilation (drying) of resting areas.

- Limited noise.

- Disadvantages :

- Limited air speeds.

Positive pressure ventilation duct

- Length : Case by case.

- Width : One row of cubicles or a double row head-to-head.

- Advantages :

- Limited electricity consumption.

- Adaptable in low-height buildings, or low position above cubicles.

- Disadvantages :

- Limited air speeds at animal level.

- Limited working width.

- Design and implementation constraints.

Priority order when installing fans

| Priorities | Conventional milking | Robotic milking |

|---|---|---|

| 1 | Waiting area | Resting areas, feeding access zone and waiting area in front of robots |

| 2 | Resting areas and feeding access zone | Traffic aisles between rows or behind cubicles |

| 3 | Traffic aisles between rows or behind cubicles |

Cost

The annual cost of a properly sized mechanical ventilation system, including loan repayment and operating costs (electricity), averages 47 to 80 euros per cow per year (amortized over 10 years).

Installing misting or showering systems

The use of water in the form of misting or showering to cool animals is only feasible under certain conditions and precautions, as it is important not to increase the air humidity level (to avoid raising the THI). The principle consists of spraying cows with a fine mist, and the evaporation of the water spread ensures cooling of the animals and a repellent effect against insects.

Some good practices for misting and showering :

- Sequences must be intermittent and the use reserved for the hottest periods with limited humidity. The watering frequencies are :

- every 5 minutes for severe stress.

- every 15 minutes for less severe cases.

- Warning, misting and showering must be avoided in overly enclosed buildings, especially in the vast majority of milking parlors which are often poorly ventilated.

- Cool dry cows starting from 4 weeks before calving (shade + watering + ventilation).

- Nozzles must not be placed on cubicles or straw-bedded areas. They should be behind the headlocks or feed barrier and in exercise areas.

- Installing such systems requires compatible infrastructure. Often, it is difficult to cool cows because sprinklers are located in windy places that disperse the mist before it reaches the animals.

Misting

- Principle : Cooling around the animal.

- Advantages :

- Misted zones appreciated by cows.

- Limited water consumption.

- Disadvantages :

- Gathering of animals in misted zones if fan equipment is too heterogeneous.

- Regular maintenance required for high pressure.

- Comments :

- Cleaning and unclogging of nozzles must be regular in high pressure systems.

- The building must be very well ventilated.

There are two types of misting : low pressure and high pressure. For misting to be effective, the droplet size must be limited.

Low pressure misting can only be used if it is projected towards the fans to break up the droplets.

Priority order when installing misting systems

| Priorities | Conventional milking | Robotic milking |

|---|---|---|

| 1 | The waiting area | The lying areas, the access zone to the feed barrier, and the waiting area in front of the robots |

| 2 | The access zones to the feed barrier | Misting throughout the building if it is fully equipped with fans |

| 3 | Misting throughout the building if it is fully equipped with fans |

Showering

- Principle : Direct reduction of body temperature.

- Advantages : Faster reduction of body temperature.

- Disadvantages : Water consumption.

- Comments :

- Showering can be done in the waiting area (in conventional milking) or at the feed barrier, or even in an outdoor exercise area.

- The building must be very well ventilated.

Priority order when installing showers

| Priorities | Conventional milking | Robotic milking |

|---|---|---|

| 1 | The waiting area | The access zone to the feed barrier and the waiting area in front of the robots |

| 2 | The access zones to the feed barrier |

Cooling mattresses

Bioret offers a air-conditioned version of water pocket mattresses for cubicles. This mattress allows :

- equal pressure over the entire contact surface. Blood circulation is thus optimal, especially in the udder area.

- to capture calories : heat transfer by contact is recognized as the most efficient.

- to dissipate heat.

- to evacuate calories outside the barn and return them to a water/water or air/water heat pump. Depending on the farmer’s needs, this heat can be used to clean the milking installation, heat calf drinking water, or supply a hay dryer. According to Bioret, it is possible to heat up to 2.5 m³ of water to 50°C per day with 50 cows.

Fighting flies

With heat, the proliferation of flies accelerates and harms the environment of livestock herds. It is therefore necessary to fight flies as soon as they appear to prevent their proliferation.

For more information on control methods, see this article.

Decision support tools

- Self-assessment from the Chamber of Agriculture, Evaluate the welfare of your dairy cows during heat waves

- ↑ Julien C., Bachelet A., online, How to protect animals from heat stress in buildings or pastures?, Web-Agri

- ↑ Fagoo B., Pavie J., online, In heat stress situations, react to protect animals, Institut de l'Elevage.

- ↑ 3.00 3.01 3.02 3.03 3.04 3.05 3.06 3.07 3.08 3.09 3.10 Bonnefoy JM., Noordhuizen J., Managing heat stress in dairy cows, Bulletin des GTV.

- ↑ 4.0 4.1 4.2 Chamber of Agriculture Nouvelle-Aquitaine, Climate change : it’s heating up for your dairy cows.

- ↑ 5.0 5.1 5.2 5.3 Fagoo B., Improving thermal comfort of dairy cows in buildings during hot periods : Practical solutions for building adaptations, Cniel.