Optimizing Herbicide Application

By definition, a herbicide is always toxic. Optimizing its use means giving yourself the most guarantees of its effectiveness with the lowest possible doses. Conversely, misuse can result in an almost total loss of effectiveness at a higher cost and pollution.

It is possible to optimize the effectiveness of herbicides during their use through preventive and curative methods :

- Knowledge of weeds to better combat them.

- Low volume technique for glyphosate.

- Preventive and curative agronomic levers.

- Taking into account the different application conditions (weather, spray mixture preparation, spraying equipment, etc.).

The effectiveness of a herbicide greatly depends on external factors, the development stage of the weed, the application period, and the equipment used. Better control of herbicide application helps reduce the IFT and is part of an agroecological transition.

Weather conditions

- Humidity : During drought, the leaf cuticle tends to thicken and will prevent the herbicide from penetrating the plant. The optimal humidity is 70% or more.

- The wind : It can cause drift away from the targeted area and drying of the leaf surface. It must be below 19 km/h.

- The temperature : For most products, it should be between 5 and 20°C, avoiding day/night temperature swings greater than 15°C.

- Soil moisture : It must be sufficient to promote absorption (especially for root / pre-emergence herbicides).

- The rain delay : Heavy rain can cause herbicide leaching; it must not rain within 2 hours after treatment[1].

Soil condition

Pre-emergence herbicides are highly dependent on the physical condition of the soil.

- Applications will be uneven on a too cloddy soil and the breaking of clods will expose soil that has not received product.

- If the soil is covered by a dense mulch, the spray will be intercepted and will not reach the root zone.

- If the soil is too waterlogged, there is a risk of phytotoxicity.

- The availability of the herbicide in the soil solution depends on the texture :

- The product is adsorbed by clay platelets or organic matter colloids. In this case, the application dose must be increased.

- In sandy soil, the risk of phytotoxicity is increased, since all the applied product is available.

Application conditions

The first rule to reduce quantities without impacting performance is to spray under good conditions (climatic, equipment, vegetative), and other factors must be considered:

- The dose : The effectiveness of a herbicide depends on the applied dose with a minimum effective dose that can vary depending on the target plant and application period (efficacy spectrum).

- Choice of nozzle and spraying equipment : Use equipment adapted to herbicide spraying, equipped for example with flat fan nozzles (obtained with brush or mirror nozzles). Moreover, special care must be given by operators for adjustment and maintenance after use (rinsing, cleaning, ...).

- Calibration of equipment must be regularly checked to correct equipment defects (worn nozzles) or operator errors; the amount of spray mixture applied per hectare must be determined to calculate spray mixture dilution.

- The application technique must be well mastered; it is essential that the distribution over the treated surface is perfectly homogeneous.

- Target the stage of the weed.

Spray mixture preparation & water quality

Adjuvants

Adjuvants are not herbicidal products but improve herbicide performance without reducing the doses used. There are 3 types of adjuvants : [1]

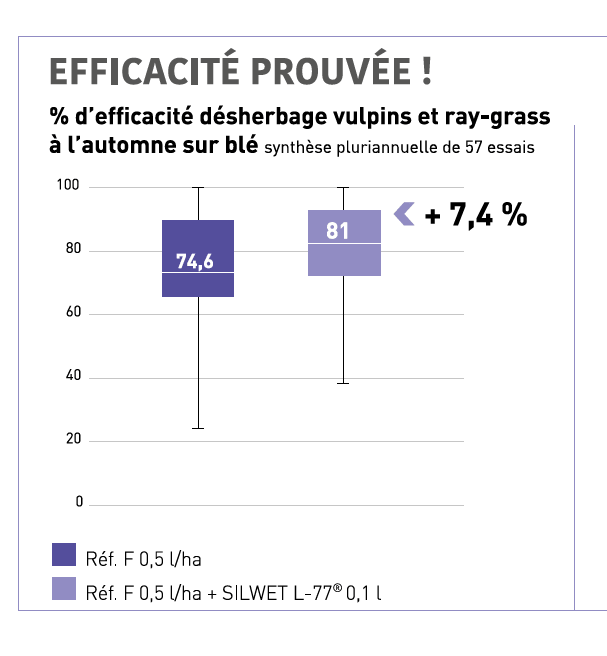

- Wetting agents : spread droplets and help them adhere better to foliage. Their effectiveness depends on the "wettability" of plants (e.g., Biofix, Break Thru S240, etc.)

| "Wettable" plants | "Less wettable" plants |

|---|---|

| All grasses (Black-grass, ryegrass, wild oats, etc.) |

- Oils : facilitate product penetration into plants and are used with systemic products on less wettable plants (e.g., Actilandes, Actirob B, etc.)

- Humectants : prevent desiccation by capturing moisture from the air (e.g., Actimum, Jonxion, etc.)

Adjuvants also have various roles from spray mixture preparation to spraying :

- Precipitation and excessive foam in the tank : Adjuvants limit undesirable phenomena and maintain the physicochemical properties of the spray mixture within optimal ranges.

- Spray quality : Especially by improving the spray jet (less drift, homogenization of droplet size, higher proportion of droplets).

- Droplet spreading and retention on surface : Adjuvants allow good distribution of the spray mixture over the soil surface and better retention of the product on leaf surfaces.

- Prolonged effectiveness despite rain : In case of heavy rain, herbicides can be leached; adjuvants help the herbicide remain in the top centimeters of soil despite heavy precipitation.

- Overall increase in herbicide effectiveness : Adjuvants increase herbicide penetration into the plant by limiting droplet explosion and bounce upon impact[2].

Spray mixture preparation

Spray mixture preparation is also an important element of spraying : It is essential :

- To use good quality water for spray mixture preparation : In particular, monitor the pH, conductivity, temperature of the water, and its hardness. The latter can be managed using ammonium sulfate.

- To ensure homogeneity of the mixture.

- To use a filter.

Solutions such as AG'EAU-VITAL allow water preparation to increase the solubility of phytosanitary products to 95% (versus 40 to 60% normally) and regulate water temperature to 22°C. Such solutions can increase the effectiveness of chemical weed control by 30 to 50%.

In order, to prepare the spray mixture, you must :

- Fill the tank to 2/3 with the desired water

- Stop filling and start agitation

- Add products acting on water quality (acidifier, water hardness corrector, ammonium sulfate)

- Incorporate phytosanitary products in the following order :

- Solid formulations

- Liquid formulations

- Adjuvants (details in the chapter above)

- Add the remaining 1/3 of water to the tank

Respecting manufacturer recommendations

Successful herbicide application also depends on following the manufacturer's recommendations.

- Product mixtures during the same application must consider the characteristics of each active ingredient used, to avoid unnecessary or even counterproductive combinations and to adapt the doses to be applied. Note that the same product can change formulation, for example changing pH level, suddenly making it unsuitable for mixing with other products. Always check labels even on "known" products.

- Respect the recommended intervention timing. For example, pre-emergence products must not be applied on already emerged plants. Post-emergence herbicides are applied according to the weed development stage, especially if they have contact action.

- ↑ 1.0 1.1 Chamber of Agriculture Ile de France, 2019 : Evolving crop rotations and optimizing technical itineraries http://www.ile-de-france.chambagri.fr/pro77/rep-agronomie/grande_culture/files/181221_Guide_culture_2019_internet.pdf

- ↑ AFA, 2014 : Adjuvants, a tool for optimizing phytopharmaceutical protection https://ecophytopic.fr/sites/default/files/2020-04/AFA%20-%20BROCHURE%20TECHNIQUE%20-%20%C3%A9dition%202014%2011%2028%20-%20LIEN%20PUBLIC.pdf

- ↑ Sangosse, 2022 : Securing autumn weed control thanks to adjuvants https://www.reference-agro.fr/innovation/securiser-le-desherbage-dautomne-grace-aux-adjuvants/