Improve Your Corridor Silo Through Audits

114 silo audits on maize silages were conducted in winter 2020-2021 by Eilyps and now allow us to draw some observations and recommendations: points to monitor, conclusions to be drawn, strengths and weaknesses of a silo.

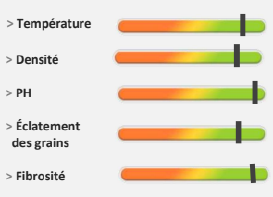

Parameters to monitor

Several parameters must be monitored in your silo. This is done notably using infrared technology and a thermal camera. Conducting an audit with an equipped expert is a good way to identify the weaknesses and strengths of your silo.

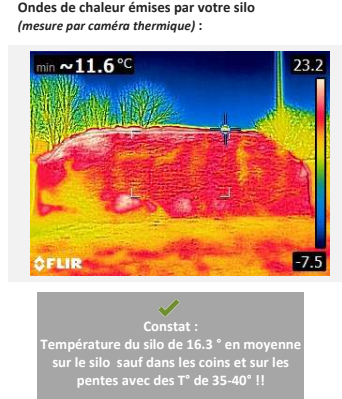

Temperature

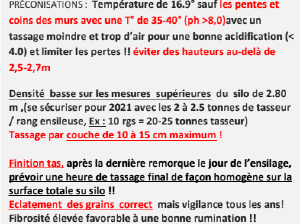

For the temperature to be homogeneous, there must be effective packing, and a silo without air ingress. If it is not homogeneous throughout the silo, the method should be reviewed and the silo should be packed at the end, preferably for one hour but at least between 30 and 45 minutes.

At the top and sides of the silo, it is common to find warmer zones corresponding to less well-packed areas. The temperature 10 cm inside the silo must not exceed the ambient temperature by more than 5°C. A warm silage results from prolonged respiration of molds, yeasts and bacteria following slow filling of the silo, air infiltration, too long chopping, poor packing or insufficient advance of the feed-out face.

The silo temperature is measured using a thermal camera.

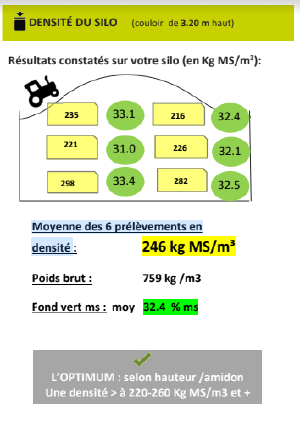

Density

When designing a silo, the farmer defines their silage needs. Density first allows calculating how much DM is available in the silo. It should be as high as possible; it is considered acceptable above 220-260 kgDM/m3. With a 4m silo, density can even reach 300 kgDM/m3.

Density results from several parameters:

- Silo height.

- Layer height.

- Average weight of the tractor(s).

- Number of tractors compacting.

- Thickness of the packing layer.

- Delivery speed of the silage.

- Compaction time.

For better compaction, attention must be paid to tractor tire slippage, meaning the slope must not be too steep.

If densities measured at the edges of the silo are not high enough, the packing method must be reviewed.

pH

The speed of pH reduction is very important; silage must become acidic as quickly as possible to prevent mold. pH must be below 4 for maize and between 4.5 and 5 for grass silage. If pH is too high, molds can develop. This often occurs on the edges of silos, indicating excess air and poorer packing in these areas.

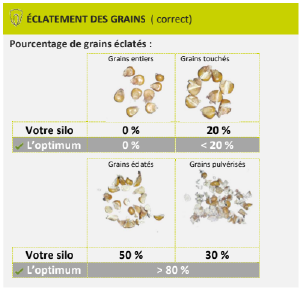

Maize kernel breakage

For good breakage, maize kernels must be broken into mostly 4 to 8 pieces in the silage. Optimal rates are 0% whole kernels, less than 20% slightly damaged kernels, and more than 80% broken or pulverized kernels.

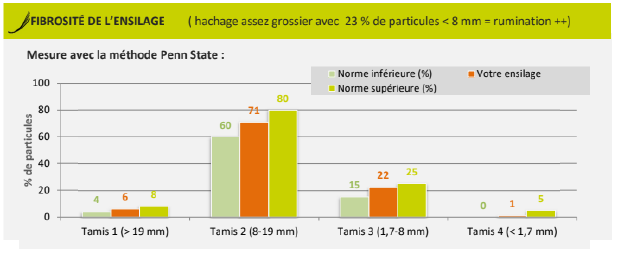

Silage fiber content

It must be sufficiently high to promote good rumination. The Penn State method is used, passing the product through different sieves to obtain the different portions of the ration by particle size (a 19mm sieve, an 8mm sieve, and a 1.7mm sieve).

First, silage is passed through the 19mm sieve. Particles retained are larger than 19mm. Then the 8mm sieve, then the 1.7mm sieve, yielding the desired proportions.

A fine ration allows good digestion but too fine a ration leads to insufficient chewing by the animal, which then does not produce sodium bicarbonate. The rumen pH decreases to 5, impacting the ration utilization and causing a drop in the BAC. Manure and milk production can also be monitored as good indicators of ration quality.

Nutritional value of silage

Infrared analysis of the feed-out face allows faster determination than chemical analysis of the silo composition and deduction of various nutritional values.

| CHEMICAL ELEMENTS (IR analysis) | Results | Assessment | Reference value |

|---|---|---|---|

| DM | 32.4 % | 32-35 % | |

| Crude Protein | 73 g/kgDM | >70 | |

| Starch | 309 g/kgDM | >320-330 | |

| RDS | 79 % | ||

| NDF | 411 g/kgDM | 400-420 | |

| ADF | 213 g/kgDM | 200-210 | |

| CC calculated | 195 g/kgDM | 180-190 | |

| Ash | 33 g/kgDM | 32 | |

| Fat | 27 g/kgDM | 25 | |

| Digestibility | 70.1 % | 69-70% | |

| CALCULATED NUTRITIONAL VALUES | Results | Assessment | Reference value |

| UEL | 0.98 | <0.95-0.96 | |

| UEB | 1.07 | <1.04-1.05 | |

| UFL | 0.97 | >0.96-0.97 | |

| UFV | 0.92 | >0.91-0.92 | |

| dOM | 72.3 | >73-74% | |

| DIP | 61 | >61-62 | |

| RPB | -37 | >-40 | |

| DIPAO | 11 | >11-12 |

If the farmer does not achieve a correct dry matter content, between 32 and 35%, losses will occur. Indeed, above 38-40%, silage is more likely to spoil. The chop length (8-10mm) must then be adjusted to limit this. If below, animals will ingest less forage and thus produce less.

Recommendations

All these factors and the difference from their optimum cause losses. On average, financial losses are 3 to 5%, but can reach 15-20% in severe cases. An audit allows issuing recommendations to reduce these losses. These recommendations must be case-by-case but from the 114 audits conducted, some points emerged:

- Strong impact of silo design height on density.

- % starch also impacts density according to a scale of +14-16 kg DM / +3 starch points at equal height.

- Chop length does not influence densities if adapted to DM, knowing that above 18 mm, it is mostly shredlage.

- At high DM content (>38%), density is maintained at average level if chop length is below 10-12 mm.

The following recommendations were formulated:

- For each trailer load, spread over a maximum surface for a 10-15 cm layer.

- Compact each layer before adding a new one.

- Respect a packer weight of 2 to 2.5 tons per forage harvester row... 10 rows = 20 to 25 tons.

- When silo size allows, having 2 tractors is favorable (one packer and one pusher) compared to one tractor of equal weight.

- Adapt chop length to DM content.

- Use a quality tarp for perfect anaerobic conditions and excellent preservation.

- Load the silo with tubes around the perimeter, and every 3-5 m across the silo (avoid any possible air ingress).

- Use a preservative containing homofermentative and heterofermentative bacteria (to be planned before ensiling).

- Keep the silo closed for 3 to 4 weeks mandatory to optimize rapid pH reduction (< 4.0).

For further reading

Also see the page on Conditions for successful silo establishment.