Fencing Your Grazing Plots

Choosing your fencing equipment means adopting your grazing management style. Building a fence should be considered an investment conditioned by the animal species to contain, the parcel layout, topography, watering points, and access paths. All of this depends on the available financial resources and the expected lifespan. Well-installed fences save time daily : quick maintenance, easier paddock changes, etc. Well-fenced pastures help to properly control grazing and increase pasture yields.

Choosing your fence

Mechanical strength and electrical conductivity are essential to judge the quality of a fencing wire. For permanent fences, robust steel wires with a substantial zinc coating (type « high tensile ») must be used. Electro-plastic fencing wires should only be used for mobile fences.

Fixed fence

Wire mesh

- Traditionally used in sheep farming.

- Medium tension for traditional and high for high tensile on wooden or iron posts.

| Advantages | Disadvantages |

|---|---|

|

|

Posts (ø 10cm) should be spaced 2.5 to 3 m apart for traditional mesh and up to 5 m for « high tensile » mesh. Solid corner posts (ø 20cm) with braces should be installed.

With classic mesh, it is necessary to install 2 to 3 steel support wires which will be tied to the mesh to reinforce the lower and upper lines.

Smooth or fixed tape wire

- Ideal for cattle and horses

- Low wire tension (around 25 kg)

- Electrification either by mains connection or with a battery and solar panel.

- Installation cost : €150/100m

- Installation : 2 wires and posts every 10 m

| Advantages | Disadvantages |

|---|---|

|

|

Smooth wire ø 1.6 mm (or tape 12 to 40 mm wide) is fixed using insulators nailed or screwed onto wooden, fiberglass (splinters during installation / dust when cutting), or concrete posts. Posts should be placed every 10 to 15 m. Commonly, 2 or 3 rows of wires (or tape) are found with ideally a circuit breaker every 600 m. When the fence borders the parcel with a hedge, 1 to 2 wires suffice. The wire height is chosen by the placement of the insulators. High-strength wire allows good fence aging and remains flexible with tensioners and springs on the line.

“High Tensile” wire

| Advantages | Disadvantages |

|---|---|

|

|

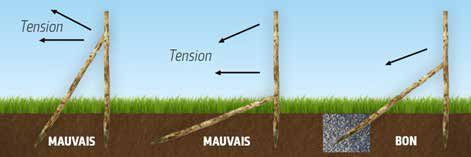

High tensile smooth wire (tension of 200 kg and more) ø 2.5 mm is fixed on wooden posts using screwed insulators. Commonly, 1 to 3 galvanized wires on wooden posts spaced 10 to 20 m apart depending on the terrain are found. Due to the required wire tension, very robust corner posts (railway sleepers or stakes over 20 cm diameter, driven one meter deep) with a brace are necessary. Installing this type of fence requires technical skill and should be discussed with the supplier. On corner starts, the use of tension insulators (4 € for 6) is essential.

Tensioners and springs are also essential for durability and robustness of the fence. There is no breakage on this type of fence (except under extreme conditions) and it requires little maintenance. Animals naturally maintain the area under the fence. However, the fence requires strict monitoring of electrification and surrounding vegetation to limit current loss.

Barbed wire

| Advantages | Disadvantages |

|---|---|

|

|

Posts (ø 10-15 cm) should be placed every 3 to 6 m and corner posts sufficiently sized (ø 20 cm). Well-tensioned wires are held by staples on the posts. Mechanization is possible with a barbed wire layer (cost €15,000 to €20,000 often purchased with a CUMA) which corresponds to a cost of €0.35 per linear meter (lm) of machine billing. Post installation can also be mechanized. The price per linear meter is around €260/100 m for a fence with 4 barbed wires and posts every 3.5 m.

Posts

Posts serve to hold the wires. In the case of electric wires, if the posts are not insulating, the wires must be fixed using insulators that prevent contact between the wire and the support (thus with the ground).

Wood choice

It is preferable to choose posts made of chestnut or acacia preferably and rather split wood. These woods have little sapwood and are naturally resistant.

Then, there are posts made of oak (very resistant but with sapwood and thick > risk of rot and breakage at the soil/air interface).

Coniferous species should be avoided as they deteriorate over time.

Installation

Posts should be 2 to 2.5 m long to have corner posts driven 50 cm to 1 m into the ground.

Particular attention is needed for corner posts; they are the framework of the fence and guarantee its durability. Other posts are then installed at variable distances depending on the chosen material (wires, mesh, or tapes), the number of wires, and the terrain. To make corner posts, railway beams can be used and set in concrete or braces made as shown in the following diagram.

Wires

Wire, tensioners, and springs

On a smooth wire, mesh, or high tensile fence, tensioners and springs are essential to allow the fence to work and last over time. It is recommended to place a tensioner (€4) every 500 - 600 m and a spring (€12) every 400 - 500 m. There are tensioners that allow not cutting the wire unlike springs.

The ideal spring tension is 90 - 120 kg. Regarding the wire, it is recommended to choose ø 2.5 mm wire for good longevity. For horses, colored smooth wire exists so the animal better perceives the fence.

Pasture entrance gates

As many gates as necessary but as few as possible should be installed. Indeed, gates are the weak point of fences. A spring (€10) allows an extensible gate up to 5 m; rope or tape (€20) are more visible. Galvanized gates are a good choice but require installation time and a higher budget (€200 to €280 depending on the desired width).

Insulators

There is a wide variety of insulators. Some are designed to keep wires away from fences, others serve simply as wire guides (which maintain the wire at the desired height).

Whatever the model chosen, the insulator must allow fixing the tensioned wire to the wooden or metal post without touching the post (which would cause grounding and make the fence ineffective). If the posts are plastic or fiberglass, insulators are unnecessary.

To fix wires to fiberglass posts, spring wire guides should be used, which allow easy height adjustment. Choose a solid and easy-to-install insulator that meets your needs.

Mobile fence

Mobile electric wire

The advantage of this type of fence is that it is easily movable and transportable. It allows quickly setting up or dismantling a fence of 1 to 3 wires. The wires are generally held by plastic or fiberglass posts spaced 8 to 10 m apart. There are systems that allow storing the posts and wires, carried either by the farmer or by a vehicle such as a quad.

Installing a fence for 1.5 ha takes 1 hour. This system is ideal for grazing catch crops, subdividing a pasture to stimulate grazing.

The cost of posts and 2 electric wires is around €100/100 m.

Mobile electric net

This is a mobile device that allows creating a paddock quite quickly (about 15 minutes for 50 ares).

This type of system is more hermetic than a classic 2 or 3 smooth wire electric fence, mainly used in sheep farming with ewes with lambs.

However, the net consumes more electricity and is less effective in situations with high biomass. Even without animals to contain, it is necessary to maintain the net electrification to prevent rodents such as rabbits, coypus, or others from gnawing the mesh.

The price of a mobile net with integrated posts is about €160 to €220/100 m.

Pasture spider

This is a tool adapted to wire grazing for cattle. It works like a fence post but is much easier to move.

Two of the 6 arms touch the ground without touching the wire; the other four rods are electrified and thus touch the wire.

The big advantage is that one person can move the fence very easily.

A spider should be placed every 25 m.

The unit cost of a spider is €60.

Points of vigilance

In a well-designed fence, current does not flow except when an animal touches the wires.

The energizer

It must be fixed in a secure place (beware of theft) and dry. It is advisable to place it as close as possible to the fence start.

Beware, the energizer is a significant expense item, from €100 to over €1,400 (if charged from solar panels).

Distributor websites offer tools to help you choose your energizer.

The grounding

This is the determining element of fence effectiveness : current must be able to flow into the ground.

The soil hosting the grounding device must be loose and moist to be a good conductor. In the shade, the grounding is more effective. For a fixed energizer, 3 stainless steel grounding rods of 1 m are needed; for a mobile one, 1 stainless steel grounding rod of 1 m.

The fences

For electric fences, you must test them with a voltmeter to know their "performance" at different points in the circuit. These measurements will serve as reference to verify its proper functioning in the future.

Priority testing should be done at "problem" spots : connections, crossings, places with many joints, near hedges, etc.

Sources

- Chambre d’Agriculture Centre-Val-de-Loire.2022.Fences for controlled grazing in peace.

- Electric fences : good practice guide CIHEAM - IAMM